Bundled light is a core element of Industry 4.0, in which the virtual, digital world is connected to real manufacturing.

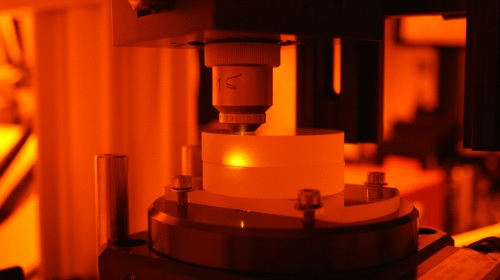

Localised welding in glass by way of ultrashort laser pulses © Fraunhofer IOF

The laser is the universal tool in production: It cuts, hardens, welds, polishes, measures, produces microstructures, traces errors and removes material. In the process, lasers impress with their high precision and speed. In contrast to mechanical tools, bundled light works on a contact-free basis and does not wear out even when processing high-strength steels or hardened glasses for smartphones. The fact that lasers are so widely used in production technology today is thanks in part to Fraunhofer.

In the last few decades, scientists, particularly from the Fraunhofer Light & Surfaces group (see box on page 8 and interview on page 14), have provided crucial impetus both in the development of new lasers and for their integration into production. Through research and development on behalf of laser manufacturers and innovative users, they contributed to Germany's current leading position in this market.

According to the industry report of the associations Spectaris, VDMA and ZVEI as well as the Federal Ministry of Education and Research (BMBF), approximately 35% of the ray sources sold worldwide and 20% of laser systems for material processing come from Germany.

© Fraunhofer ILT

However, the potential of lasers is far from exhausted. Fraunhofer researchers work on next-generation lasers, readying them for use in production. An example is the high-performance ultra-short pulse laser (USP laser). It produces light pulses that are only a few picoseconds or femtoseconds short (trillionths or quadrillionths of seconds), but are very rich in energy.

For the sake of comparison: While a ray of light requires approximately one second to go from the earth to the moon, in a picosecond it travels only 0.03 millimetres. Important foundations for the development and use of ultra-short pulse lasers were laid by experts of the Fraunhofer Institute for Applied Optics and Precision Engineering (IOF) in Jena and of the Fraunhofer Institute for Laser Technology (ILT) in Aachen.

For instance, in 2009 scientists of the IOF demonstrated an ultra-short pulse laser with a capacity of 830 watts. In 2010, the ILT experts in Aachen surpassed the magic mark of 1kW with a femtosecond laser. Since then, 1.5kW has even been reached at the ILT with a scaled version of the femtosecond laser. However, the researchers at the ILT do not work just on performance enhancement, but they also develop tailored ray sources and new applications for ultra-short laser pulses.

But what distinguishes ultra-short pulse lasers from traditional systems? "Thanks to the expert selection of the pulse duration, the pulse energy and the right focus, the material can be heated so quickly and so strongly that it evaporates without melting," explains Professor Andreas Tünnermann, Chairman of the Fraunhofer Light & Surfaces group and Head of IOF in Jena. Material removal takes place precisely and only where it should, micrometre by micrometre.

Such "cold processing" is not possible with conventional lasers. The latter produce heat influence zones. For example, if a laser ray comes into contact with metal, the material melts partially and unevenness can form. The material must then be elaborately post-processed. This costs time and money.

Bundled light for Industry 4.0

For a few years, researchers from IWS Dresden have been developing processes and the necessary system technology in order to produce components directly using metallic materials in virtualised process chains. In the project "Additive-generative manufacturing – AGENT 3D", they are working on first designing products on the computer and then manufacturing them directly in an automated process, without further intermediate steps, as products ready for installation.

The aim is to develop additive-generative manufacturing into the key technology of Industry 4.0. To this end, a consortium has been formed with 75 partners from business and science. The research project is part of the programme "Zwanzig20 – Partnerschaft für Innovation" (Twenty20 – Partnership for Innovation) supported by the Federal Ministry of Education and Research (BMBF).

How light can be used as a tool in production that will be increasingly digitalised in future is being investigated in Aachen at the "Digital Photonic Production" research campus. Behind the term "Digital Photonic Production" (DPP) is the concept of controlling laser radiation photons with bits (computer data) and using them to combine atoms into materials – at any level of complexity and at as low unit numbers as desired, at permanently low unit costs.

"The laser is the only tool that works as quickly as a computer thinks," explains Christian Hinke, who leads the group for integrative production at the Chair for Laser Technology of RWTH Aachen University and coordinates the DPP Initiative, which is being strategically promoted by the BMBF over the next 15 years. One of the initiators and spokespersons of the DPP Research Campus is Professor Reinhart Poprawe, Head of the ILT.

The following areas of focus are being worked on at the DPP research campus: Selective laser melting, the use of ultra-short pulse lasers and selective surface processing with innovative semi-conductor ray sources, whereby the light is radiated perpendicularly to the level of the semi-conductor chip. With such vertical-cavity surface-emitting (VCSE) lasers, surfaces can be refined selectively – i.e. on a space-resolved basis – in a very efficient manner.

The ILT brings already existing activities into the research campus – for instance the EUR 10 million-strong Fraunhofer innovation cluster AdaM. In the cluster, the ILT works with organisations such as the Fraunhofer Institute for Production Technology (IPT) on generative manufacturing processes with which components for aircraft engines and gas turbines for energy generation can be manufactured.

A key objective of the DPP research campus is to connect basic research, applied research and industry more heavily with each other. For this reason, the parties involved are testing new forms of cooperation, such as the enrolment model. Here, companies take up residence on the university campus and together with the scientists from RWTH Aachen University and Fraunhofer, they research topics that go beyond the short-term interest in new products.

The companies do not just maintain small offices on the campus; their experts are also actively involved in research and education. This facilitates the knowledge transfer between science and business. The researchers find out what industry is interested in. And the companies can convert current research results more quickly into new products. Industrial groups such as BMW, MTU, Philips, Siemens and Trumpf as well as small and medium-sized companies such as Amphos, Innolite, ModuleWorks and SLM Solutions are involved at the research campus.

The Federal Ministry of Education and Research (BMBF) is supporting the project for a total of 15 years with up to EUR 2 million per year. Additionally, by the end of the year an innovation centre – financed by private investors with more than EUR 11 million – will be completed, in which interested cooperation partners from industry can rent office rooms and laboratories in direct proximity to the ILT.

With their work, Fraunhofer researchers contribute to making production using light as a tool fit for the challenges of the future.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login