WHEN chips are too thin, cutting takes place on a smaller portion of the cutting edge and increased friction creates heat that results in rapid wear.

Chip thickness is measured perpendicular to the effective cutting edge. As discussed earlier, the chips generated in milling continually change in thickness as the cutting edge passes across the workpiece. For programming purposes, tool suppliers utilise the concept of “average chip thickness.” The average thickness is the numerical average of the chip’s thickest and thinnest dimensions. Toolmakers provide average chip thickness data for specific tool geometries that when applied and maintained will produce maximum tool life and productivity.

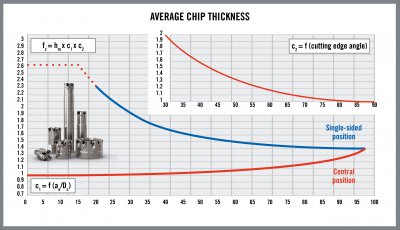

Machinists use that data to determine cutter feed rates that will maintain the recommended average chip thickness. The radial engagement of the cutter, the diameter of the cutter, the cutter positioning and the cutting edge angle of the cutting edge are factors in determining the correct feed rate. Radial engagement is defined as the ratio of the radial depth of cut (ae) to the diameter of the milling cutter (Dc). The greater the radial engagement of the cutter, the lower will be the feed rate required to generate the desired chip thickness. Similarly, with lesser cutter engagement the feed rate must be higher to achieve the same chip thickness. The cutting edge angle of the cutting edge also affects feed requirements. Maximum chip thickness occurs with a cutting edge angle of 90 degrees, so lesser angles require a higher feed rate to achieve the same chip thickness.

Sharp cutting edges produce lower cutting forces but are also more fragile than honed or chamfered edges. Mechanical load on the cutting edge must be limited to prevent chipping and breakage, so smaller average chip thicknesses are recommended when applying sharp cutting edges. In this case, the cutting edge geometry used determines the correct average chip thickness and vice versa.

Machinists can utilise these principles and methods in basic milling applications to control the intermittent stresses on milling tools. However, as part requirements become more complex — even at the level of simply milling into corners — manually changing feed rates to maintain recommended average chip thicknesses is essentially impossible. For those cases and beyond, including very complex 5-axis milling, makers of CAM software and advanced CNC equipment have developed techniques such as trochoidal milling and corner peeling as well as constant tool engagement tool path programs such as Dynamic Milling, Volumill, or Adaptive Clearing. These software and machine control advances represent the high-tech evolution of the basic concepts of management of tool entry, exit, and chip thickness to control the effects of the intermittent milling process on the cutting tool.

Manufacturers have employed milling machines and tools for more than a century, producing countless parts in high volumes and top quality. Over that time, the basic milling process has remained the same, namely the use of a rotating cutter on a workpiece to machine a surface. The intermittent cutting nature of the process has remained the same as well.

Milling machines and milling tooling have evolved to an unbelievable extent, but in many cases their users are not taking full advantage of that technical progress. Recognising the unique interaction of workpiece and tool that takes place in milling and working to moderate the intermittent stresses involved in the process enables manufacturers to achieve the rarely-attainable triple goal of maximum productivity, quality and tool life.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login