Together with local partner Thonburi Automotive Assembly Plant (TAAP), the German carmaker will invest a total of over 100 Million Euros in the production operations in Bangkok until 2020. The investment will go into an extension of the existing car plant and into a new battery assembly built on the site ensuring availability of cutting-edge technology for electrified and “EQ Power” Plug-In Hybrid vehicles produced in Thailand.

The electric initiative in the flexible and efficient global production network of Mercedes-Benz Cars is progressing well and with ultimate speed. As part of our strategy, we are now preparing for the future of electromobility in Thailand together with our partner TAAP. With our highly standardized and scalable battery production concept we are able to start operations in any region at short notice and at the right size. The battery production in Thailand will enhance our global battery production network to six factories on the three continents. Markus Schäfer, Member of the Divisional Board of Management Mercedes-Benz Cars, Production and Supply Chain.

Thanks to a standardized production and plant concept, the battery production concept of Mercedes-Benz Cars can be scaled in such a way that various value-added stages as well as production concepts can be implemented flexibly and in line with the markets worldwide.

By 2022, Daimler will electrify the entire portfolio of Mercedes-Benz, offering customers at least one electrified alternative in all segments from compact cars to large SUVs. The company is planning to offer more than 50 electrified vehicle variants. Mercedes-Benz will be continuously supporting the development of Plug-In Hybrids and the introduction of 48-volt-systems. The first EQ series model- the EQC - will go into production in 2019 in Bremen, Germany.

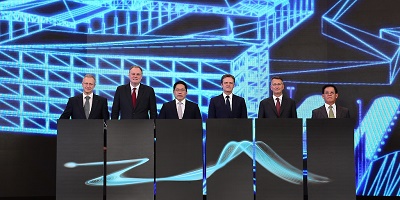

Sixth Mercedes-Benz factory to produce batteries

The battery production in Bangkok will be part of the global battery production network of Mercedes-Benz Cars for local demand and export. In total, Daimler will invest more than one billion Euros in the battery production network, which will also include production facilities in Germany, the U.S. and China. As in vehicle production, the battery production network will react flexibly and efficiently to market demand. This strategy ensures the ongoing availability of modern battery technology through local production hubs and puts Mercedes-Benz in a highly competitive position for its electric initiative. Local production of batteries in Thailand is planned to start by 2019.

Confidence in the potential of Thailand’s passenger car market

Part of the joint investment of Mercedes-Benz Cars and local partner TAAP is the extension of the existing car plant leading to a substantial increase in the production portfolio, adding new models.

In 2017, thanks to a double-digit growth rate Mercedes-Benz achieved its highest ever unit sales in Thailand with more than 14,000 units sold. The best-selling models were the E-Class Saloon, the C-Class Saloon and the CLA Coupé. Mercedes-Benz Thailand currently offers a range of nine locally-assembled models.

Crucial for the success story of Mercedes-Benz in Thailand is the close cooperation of Mercedes-Benz Manufacturing Thailand and partner TAAP, who operates the plant in Bangkok. In 2017 alone, TAAP produced over 12,000 cars for Mercedes-Benz. The plant currently employs over 1.000 people. It is expected that, once completed, the investment will create more than 300 additional jobs at the site, thereof nearly 100 for battery production alone.

Metal News Asia on Twitter

Jordan XII Slide

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login