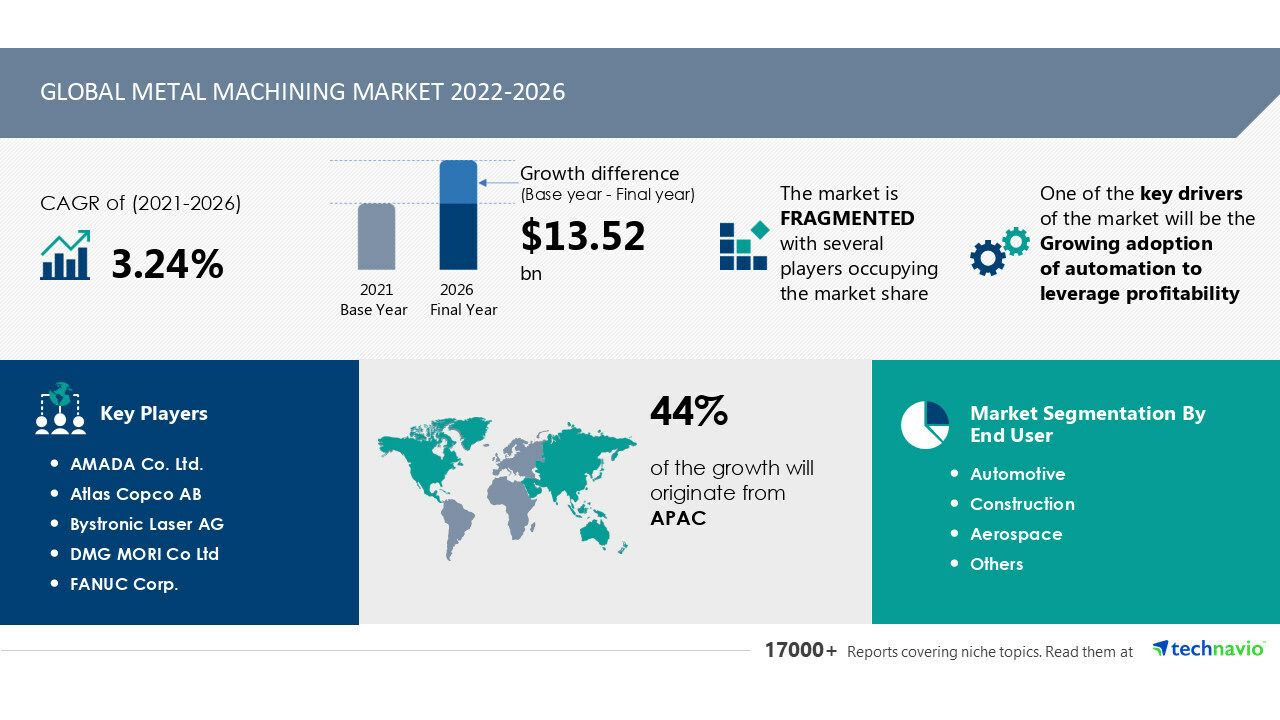

The metal machining market is projected to grow by US$13.52 billion with a CAGR of 3.24% during the forecast period 2021 to 2026 according to Technavio. The growing competition in the market is compelling vendors to adopt various growth strategies such as promotional activities and spending on advertisements to improve the visibility of their services.

The construction of equipment and structures requires extensive machining processes. The demand for metal processing machines is increasing owing to the rising investment in infrastructure projects around the world.

Real-time data collection is one of the strengths of IoT solutions across the metal process. Employees can evaluate whether the components within a workflow are delivering the expected or intended results and whether there is an opportunity for improvement, making the overall workflow a more efficient manner. The industrial Internet of Things (IoT) can also prevent the problem of sudden machine failures that interrupt workflows. Organisations might miss deadlines or have to reduce the number of specialists working particular shifts as a result of broken metal fabrication machines. IoT sensors can anticipate these challenges by capturing operational information that indicates abnormalities or that a machine requires maintenance to prevent problems. Hence, the emergence of IoT in the metal fabrication industry will drive the growth of the metal machining market during the forecast period.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login