THE continued growth of China’s economy in recent years has contributed to the busy lifestyles of city dwellers in the country. This has affected consumer preference as they seek convenience products, to fit better with increasingly active and mobile lifestyles. As such, manufacturers have to produce food products that suit these preferences – and that can be consumed on-the-go. This means that consumption of goods such as pre-packed fruit and salads and ready-made meals is rising, while snacking products such as packaged nuts and seeds, and breakfast cereals are also very popular. In food inspection terms, these products provide challenges, due to the complex, variable density of the food stuffs and also the innovative packaging they come in. Stones in grains and cereals, salads, dried fruit and vegetables are common contaminants, and rice products are commonly contaminated by stones and glass.

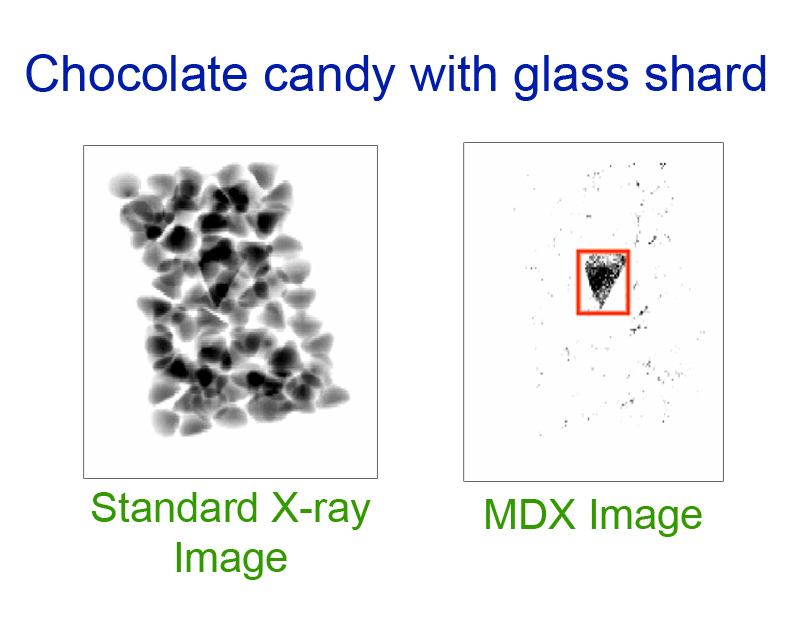

The MDX by Eagle Inspection Technology can identify foreign objects in mixed-textured products, a capability not found in standard x-rays

Conventional x-ray inspection technology is excellent at detecting certain types of contaminants in food products. Stainless steel, ferrous and non-ferrous metals, glass, calcified bone, mineral stone, and high density plastics and rubber can all be identified in food products and rejected accordingly. However, conventional x-ray technology has difficulties detecting inorganic contaminants such as glass shards, low density plastics and rubber, and stones or rocks within a complex density product i.e. product with high variations in density, such as instant congee. Typically, the image produced by conventional x-ray technology in such products is crowded and indecipherable.

Clearly, this is a problem for food manufacturers, even more so in an age when consumers are increasingly conscious of food standards issues, especially after the series of food scandals in China. There have been a number of complaints and reports of glass shards and foreign bodies found in instant food products in China. When these problems occur, brand reputations are at stake and no manufacturer wants to endure the embarrassment, not to mention the short- and long-term costs, of a product recall due to contamination of food by objects that should have been removed before reaching the supermarket shelves.

A ground-breaking solution

It is for this reason that Eagle Product Inspection has harnessed its cutting-edge Material Discrimination X-ray technology, or MDX, for use by food manufacturers. MDX is an enhanced dual energy x-ray technology that can discriminate between high and low x-ray channels. When x-rays are directed onto a food product, a proportion of the x-ray energy is absorbed by the product, depending on the product’s composition, while the rest of the energy passes through to a detector.

Each ingredient in a product has its own atomic number, and the higher the atomic number, the greater proportion of x-ray energy is absorbed. Carbon, with an atomic number of six, therefore absorbs much less x-ray energy than lead, which has an atomic number of 82. MDX has a detector array that gives values at two different energies and a relative ratio of energy absorbed can be calculated to determine a material’s composition. Foreign body detection therefore becomes based on chemical composition i.e. atomic number rather than just density variation or product thickness.

Material Discrimination X-ray technology (MDX) tells apart objects based on chemical composition and not only on density variation or product thickness

MDX can detect flat glass and stone in mixed nuts, for example, which conventional x-ray finds very challenging. Nor is it just the food within the packaging that can affect detection. Innovative packaging designs such as fold-out cardboard sandwich packaging and corrugated card encasements also provide challenges to foreign body detection for standard x-ray inspection technology – challenges that MDX is able to overcome.

The development of MDX for product inspection has followed the demands of food manufacturers that need a reliable solution to detect and remove contaminants regardless of product type or packaging format. In the case of MDX, this technology has also been used in the security industry for some years to help find contraband, weapons and stowaways in cargo containers.

Looking to the future

There are also potential future uses for MDX beyond that of the inspection of complex density food products. For instance, the technology might also be used to measure ingredients to simplify the classification of products for food labelling.

What is certain is that with modern lifestyles calling for ever greater convenience in food consumption, the issues of contamination and complexity in the food production chain are not going to go away. The consumer needs to feel confident that every effort is being made to ensure that only high quality produce makes it to the supermarket, and the damage to a brand through failing to meet these exacting standards is something that food manufacturers can ill afford. Ground-breaking x-ray technologies such as MDX can make that failure a thing of the past.

*Jeff Jia is channel sales manager (China) of Eagle Product Inspection

Nike Hyperdunk 2018

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login