THE SpeedUp module increases the speed of MULTIVAC cross web labellers when thermal transfer printers are used at low ambient temperatures. Besides speed which is crucial in printing, the new module not only enhances quality but will enable significant savings in the consumption of thermal transfer ribbon as well as shorter downtime, according to the company.

Thermal transfer printers feature a high level of print quality and flexibility as regards the print layout. These features make them suitable for product marking, since the information content on labels is increasing continually. For instance, food information regulations demand detailed information about nutritional values. Such features would also be useful in meeting demand for multilingual information on labels. Furthermore, QR codes are enjoying increasing popularity, since consumers can conveniently download additional product information to their smartphones, such as for example information on the origin of meat and sausage products.

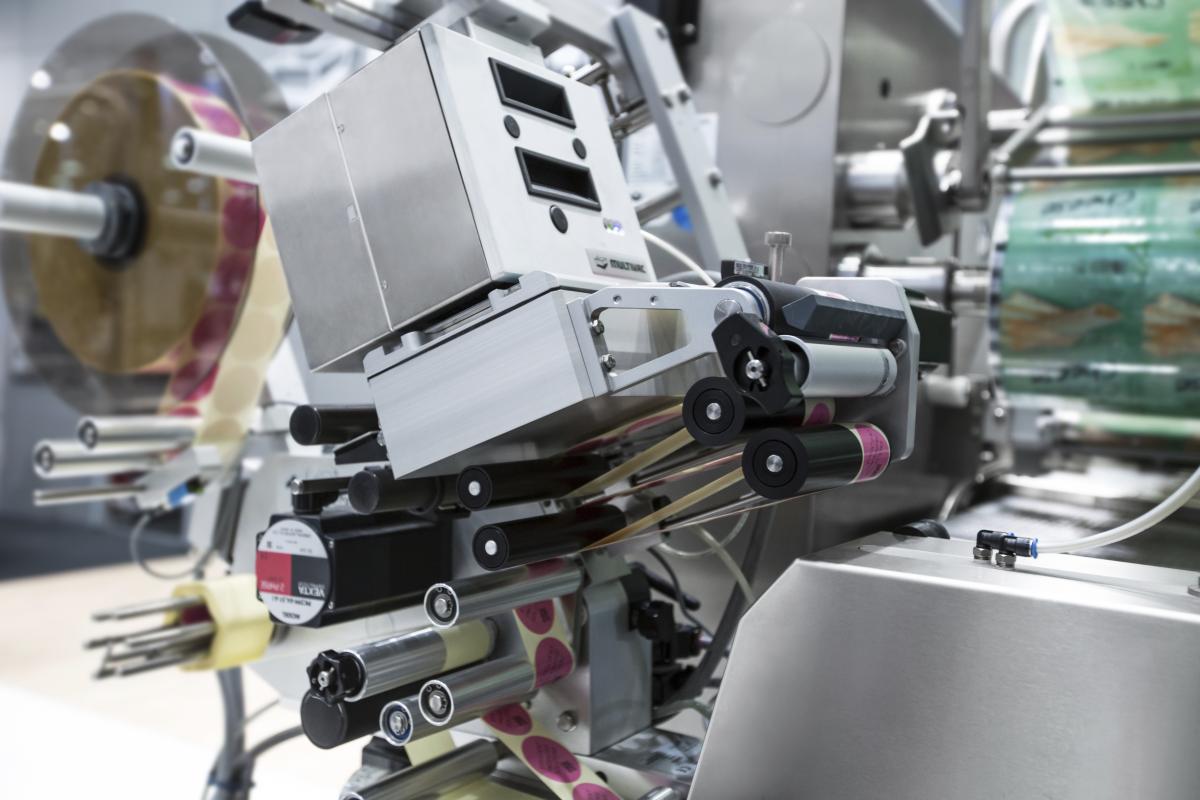

The caveat with thermal transfer printers is that they can’t achieve their maximum printing speed at the low ambient temperatures, commonly used in food processing. Since this also adversely affects the cycle output of the labeller, MULTIVAC created the SpeedUp module that consists of a servo-driven label advance and a label buffer, in which the pre-printed labels are temporarily buffered.

The module decouples the labelling process from the printing process: the printer is therefore also able to print while the labeller is at a standstill. The printed labels are advanced into the loop that serves as the buffer, are removed from the dispensing edge and then applied at maximum speed to the packs. This means that the overall line output is no longer adversely affected by the thermal transfer printer. As an option, the SpeedUp module can be extended with a holding device for an inkjet printer for simple marking tasks. In this case, there are then two printing processes available on the one line.

Working together, the SpeedUp module and the MULTIVAC TTO printers, enable customers to use the thermal transfer printers at low temperatures. Due to their intermittent operation, TTO printers are capable of being turned, so that they can print in either the longitudinal or cross direction relative to the running direction of the label. This means that the thermal transfer ribbon is used to its optimum for each print layout. Together with the only 0.5 mm gap between each print impression, this results in significant savings in ribbon consumption. If a thermal transfer ribbon with a length of 1,000 metres is chosen, as is the case for example with the TTO 10, then downtime for ribbon change is also reduced significantly.

Aside from these, the high-performance printers completely integrate into the MULTIVAC machine control and operated via the HMI 2.0 user interface of the packaging machine. Recipes are downloaded reliably and in a user-friendly way. The print layouts are managed centrally and assigned to the individual recipes, and they are loaded directly with the recipe itself. This means that incorrect labelling due to selection of the wrong label can be avoided. Since no separate printer control terminal or connection cables are required, the TTO printers also stand out from the rest due to their high level of hygiene.

Air Jordan XVIII 18

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login