SNACK manufacturers may add new shapes, sizes and flavours to their snacks using the 16-stream die from Baker Perkins. The company’s CoEx Master Systems co-extrusion product now features a 16-stream die for increased output capability. This is a step up from the previous maximum of 12 streams, providing customers with a wider range of choices now covering four to 16.

As with most of the company’s products, the CoEx Master Systems offers food manufacturers with an uncomplicated extrusion system for making standard, direct-expanded snacks such as corn curls, chipsticks and maize rings, and with options for scalability as the business grows.

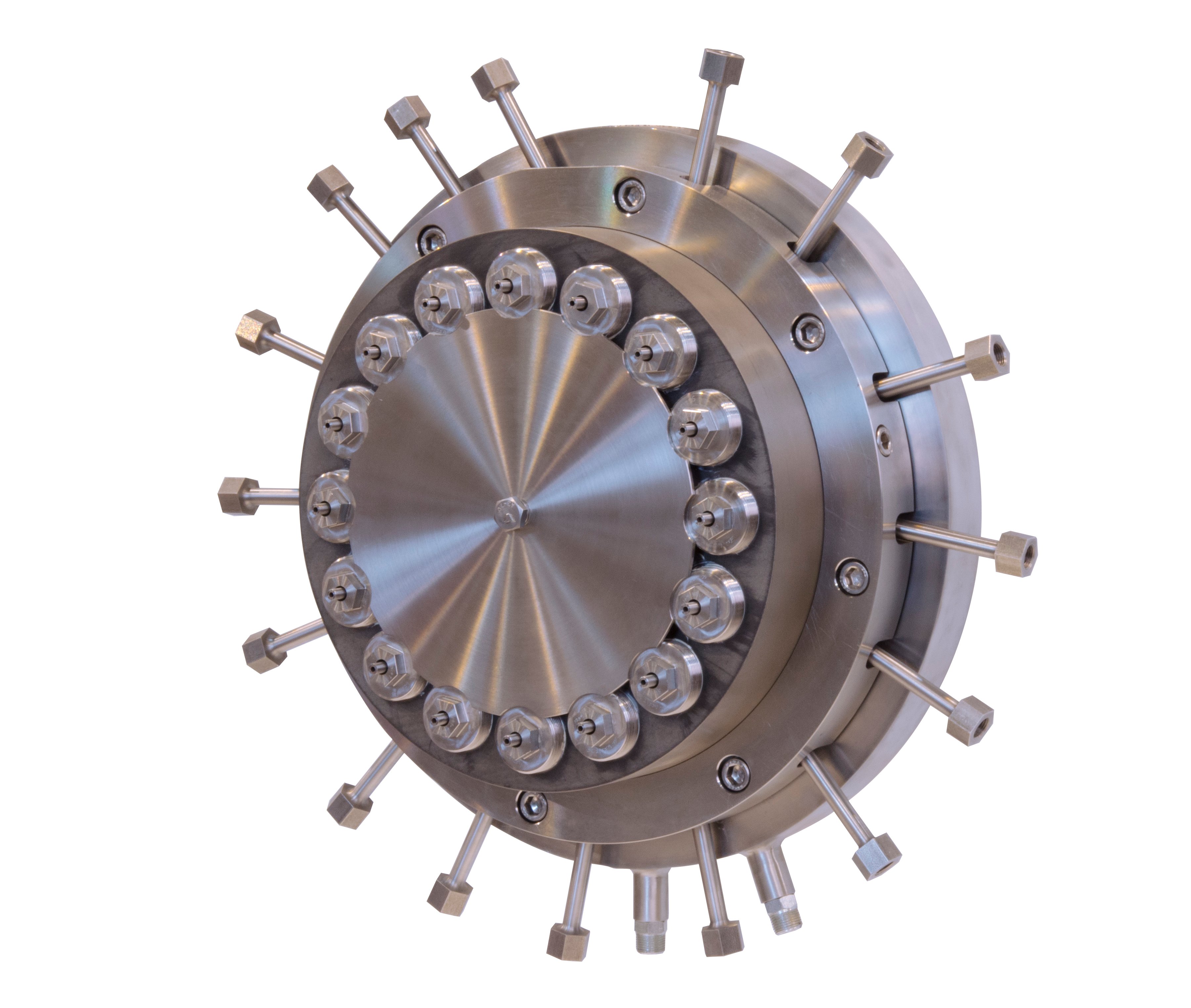

The equipment produces snacks with a cereal outer and a centre filling. The extrudate and filling combine into concentric streams at the die. The flow at each outlet can be adjusted individually to control consistency and weight. A cereal tube connected to a twin-screw extruder hosts the filling. The product also includes a cream feeder and pillow-crimper. The first supplies the die whilst the latter is where the product stream from the die is cut to length and sealed.

Baker Perkins provides customers with a wider range of choices with new 16-stream die

Simply put, name the filling and coating, and the machine may be able to do it. The typical filling flavours include sweet and savoury creams, fruit pastes, chocolate praline and cheese. Expanding this range of familiar choices are Asian, Middle Eastern and Hispanic tastes. Chilli, paprika, teriyaki, guacamole, sweet and sour, black bean sauce and a wide family of curries can also be used, individually or in combination.

Snacks can come in pillow, tube, bar, or wafer of different proportions, including sticks and bite-sized pieces. ‘Standard’ shapes such as squares are supported, and with an outline more clearly defined than that produced using older-generation equipment. Novel patterns in the form of chevrons, waves, and trapeziums can also be adopted for co-extruded pillow snacks. Even variety packs can have different shapes and flavours simultaneously.

The CoEx Master Systems, which is a component of the Baker Perkins Snack Master flexible systems, can be part of a new extrusion line or added as an upgrade. A standard line comprises an SBX Master twin-screw extruder, a dryer and a flavouring system. Special dies and cutters, co-extrusion equipment, dryers, fryers, ovens, and coolers can be added. The line can be extended in stages to support more products, including traditional and new-generation snacks such as whole grain and savoury filled pillows.

Air Max 2017

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login