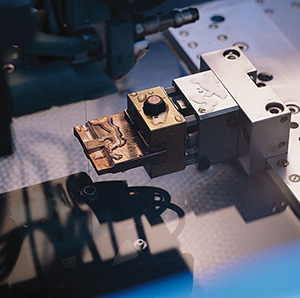

Equipping various wire electrical discharge machining (WEDM) machines with an identical tooling system is becoming simple these days. For a more productive WEDM, tool-making expert EROWA AG offers Basic WEDM Tooling, a new solution that provides good value for money.

Its basis is a flat chuck, which you fit to the Z=0 level of the WEDM machine. With an easy-to-use range of clamping accessories, workpieces of up to 10kg in overall weight can be quickly and accurately prepared outside the machine. The advantages of this system are evident.

The workpieces are set up while the machine is at work, and this saves valuable production hours. The machine is not blocked by unproductive set-up work.

Product quality increases, and parts being reproduced are made simpler. The system's repeatability of 0.002mm makes production processes easier to control.

The EROWA Basic WEDM Tooling can be modularly extended with standardised components and can thus be adapted to new requirements at any given time.

6000 hours of productivity per year

Down times on a wire cutting machine are mostly due to the fact that jobs are set up right in the work tank. There are times when the job is ready, but the NC program needs to be prepared or modified. What can be done about that? One way of pushing productive time up to the limits is the application of a suitable tooling system for holding and positioning the workpieces. EROWA presents the PalletSet W system; the best way to improve the return on investment of your WEDM machine.

Basics

The main decision is which tooling system fits the purpose of the factory best. Therefore some thought needs to be given to the size, shape, number, and variety of workpieces to be machined.

Machines

Machines with large ranges of X and Y axis travel tend to be equipped with some multiple part palletizing system, to make the most out of the entire working range. Smaller machines may not be loaded with many different parts, so the unattended production time is much shorter.

Tooling

A suitable tooling system must meet the following requirements:

Positioning accuracy of 0.002 mm: With this accuracy it becomes possible to prepare parts outside the machine, and still be sure that the workpiece is repositioned on every machine with the tooling system within the tolerance of 0.002 mm.

Ability to align parts in all axes X, Y, Z and C (swivel head): This means that work parts with finished surfaces may be aligned until they are exactly in position.

Safe and easy operation in manual and automatic mode: Only if the system checks the correct positioning automatically, it will be possible to automate the loading process if necessary.

Advantages

- It is obvious that a machine’s productivity can be enhanced by eliminating the down time. On WEDM machines, it is possible to do so with the additional gain of precision by using the PalletSet W as a tooling system.

- Valuable productive hours are gained by doing the set-up work while the machine is producing something else. The machine is not blocked by unproductive set-up work.

- Product quality is increased, and reproducibility is made easier. Thanks to the system's repeatability of 0.002mm, production processes are easier to control.

- Automation enables the utilisation of further valuable production hours at night and on weekends. In this way, 6000 productive hours per year are quickly realised.

- With the compact range of tooling accessories, workpieces of up to 30kg in weight can be prepared easily, quickly and accurately outside the machine.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login