Inkjet coding printers, such as this 9000 Series from Markem-Imaje, play a critical role in tracking and tracing food and pharmaceutical products throughout the supply chain FOOD safety has become a high-profile issue worldwide. In the United States alone, the Produce Safety Project (PSP) estimates acute foodborne illnesses cost the U.S. an estimated $152 billion per year in healthcare, lost time in the workplace and other economic measures. The 2010 study, Health- Related Costs from Foodborne Illness in the United States, by former U.S. Food and Drug Administration (FDA) economist, Robert L. Scharff, further reports that about $39 billion of those losses can be attributed to fresh, canned and processed produce. As a result, the FDA is proposing standards that would trace every individual unit of product from farm to store shelf, with complete compliance mandated by 2012. In a white paper, David Habib, product manager-Strategic Accounts and Solutions for Markem-Imaje explains how product traceability became a necessity: "The product identification process was born out of international legislation requiring almost all food and drink products to display expiration dates. For some years, the need to add date codes to packages was viewed merely as an additional manufacturing cost, but a series of major food scares affecting such products as fresh and processed meat, seafood, baby food, ingredients, and even spring water, threw the question of product traceability into much sharper focus.

Markem-Imaje is just one of dozens of processing and packaging exhibitors at PACK EXPO International 2010 (31 Oct to 3 Nov, McCormick Place, Chicago) who will feature products to help manufacturers respond to the current level of concern and bolster safety efforts. "Retailers began to be more forceful in their demands for product code accuracy, levying fines and other penalties on suppliers guilty of date and packaging errors. Manufacturers began to realise that an effective product ID and traceability processes offers a measure of protection from such issues," Mr Habib adds. Another white paper from Markem-Imaje (Booth 2200), offers help on implementing effective product traceability: "The ability to closely monitor the codes being printed on each product at all levels within the packaging line process is critical to most industries. Wrong, missing or illegible codes could lead to fines, product recalls and, potentially, products not being accepted by the retailer or customer. All of these consequences could affect your brand perception for identity and quality. Wrong or illegible codes impinge on the brand in many ways including additional labour costs, product and packaging materials, disposal of the used materials and packaging line time to potentially rework the product versus recoding and marking and verifying the mark on the product correctly the first time." In mid-2009, Markem-Imaje introduced its 9000 Series line of ink-jet coding printers for primary package coding. The versatile,

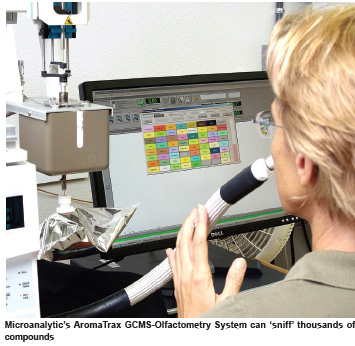

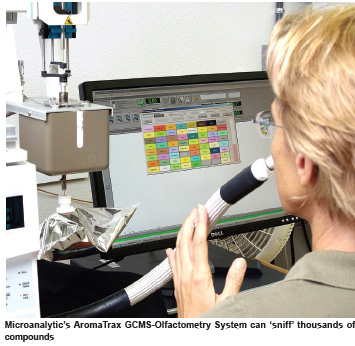

heavy-duty and reliable line comprises three printers: 9020, 9030 and 9040. With single-jet and bi-jet printheads available and a wide choice of configurations, the 9000 Series is especially suitable for the food, beverage, pharmaceutical and cosmetic industries. A large selection of inks makes printing possible on just about any substrate. An intuitive user interface and easily accessible consumables mean this series is user-friendly. Nose needed here Several recent product recalls have been sparked by consumer complaints about mouldy or musty odours associated with nausea, stomach pain, vomiting and diarrhoea. Microanalytics, a subsidiary of MOCON, Inc. (Booth 6232), has developed improved approaches to identifying the source of industrial odours and can help g

Pure Boost Shoes Inkjet coding printers, such as this 9000 Series from Markem-Imaje, play a critical role in tracking and tracing food and pharmaceutical products throughout the supply chain FOOD safety has become a high-profile issue worldwide. In the United States alone, the Produce Safety Project (PSP) estimates acute foodborne illnesses cost the U.S. an estimated $152 billion per year in healthcare, lost time in the workplace and other economic measures. The 2010 study, Health- Related Costs from Foodborne Illness in the United States, by former U.S. Food and Drug Administration (FDA) economist, Robert L. Scharff, further reports that about $39 billion of those losses can be attributed to fresh, canned and processed produce. As a result, the FDA is proposing standards that would trace every individual unit of product from farm to store shelf, with complete compliance mandated by 2012. In a white paper, David Habib, product manager-Strategic Accounts and Solutions for Markem-Imaje explains how product traceability became a necessity: "The product identification process was born out of international legislation requiring almost all food and drink products to display expiration dates. For some years, the need to add date codes to packages was viewed merely as an additional manufacturing cost, but a series of major food scares affecting such products as fresh and processed meat, seafood, baby food, ingredients, and even spring water, threw the question of product traceability into much sharper focus.

Inkjet coding printers, such as this 9000 Series from Markem-Imaje, play a critical role in tracking and tracing food and pharmaceutical products throughout the supply chain FOOD safety has become a high-profile issue worldwide. In the United States alone, the Produce Safety Project (PSP) estimates acute foodborne illnesses cost the U.S. an estimated $152 billion per year in healthcare, lost time in the workplace and other economic measures. The 2010 study, Health- Related Costs from Foodborne Illness in the United States, by former U.S. Food and Drug Administration (FDA) economist, Robert L. Scharff, further reports that about $39 billion of those losses can be attributed to fresh, canned and processed produce. As a result, the FDA is proposing standards that would trace every individual unit of product from farm to store shelf, with complete compliance mandated by 2012. In a white paper, David Habib, product manager-Strategic Accounts and Solutions for Markem-Imaje explains how product traceability became a necessity: "The product identification process was born out of international legislation requiring almost all food and drink products to display expiration dates. For some years, the need to add date codes to packages was viewed merely as an additional manufacturing cost, but a series of major food scares affecting such products as fresh and processed meat, seafood, baby food, ingredients, and even spring water, threw the question of product traceability into much sharper focus.  Markem-Imaje is just one of dozens of processing and packaging exhibitors at PACK EXPO International 2010 (31 Oct to 3 Nov, McCormick Place, Chicago) who will feature products to help manufacturers respond to the current level of concern and bolster safety efforts. "Retailers began to be more forceful in their demands for product code accuracy, levying fines and other penalties on suppliers guilty of date and packaging errors. Manufacturers began to realise that an effective product ID and traceability processes offers a measure of protection from such issues," Mr Habib adds. Another white paper from Markem-Imaje (Booth 2200), offers help on implementing effective product traceability: "The ability to closely monitor the codes being printed on each product at all levels within the packaging line process is critical to most industries. Wrong, missing or illegible codes could lead to fines, product recalls and, potentially, products not being accepted by the retailer or customer. All of these consequences could affect your brand perception for identity and quality. Wrong or illegible codes impinge on the brand in many ways including additional labour costs, product and packaging materials, disposal of the used materials and packaging line time to potentially rework the product versus recoding and marking and verifying the mark on the product correctly the first time." In mid-2009, Markem-Imaje introduced its 9000 Series line of ink-jet coding printers for primary package coding. The versatile,

Markem-Imaje is just one of dozens of processing and packaging exhibitors at PACK EXPO International 2010 (31 Oct to 3 Nov, McCormick Place, Chicago) who will feature products to help manufacturers respond to the current level of concern and bolster safety efforts. "Retailers began to be more forceful in their demands for product code accuracy, levying fines and other penalties on suppliers guilty of date and packaging errors. Manufacturers began to realise that an effective product ID and traceability processes offers a measure of protection from such issues," Mr Habib adds. Another white paper from Markem-Imaje (Booth 2200), offers help on implementing effective product traceability: "The ability to closely monitor the codes being printed on each product at all levels within the packaging line process is critical to most industries. Wrong, missing or illegible codes could lead to fines, product recalls and, potentially, products not being accepted by the retailer or customer. All of these consequences could affect your brand perception for identity and quality. Wrong or illegible codes impinge on the brand in many ways including additional labour costs, product and packaging materials, disposal of the used materials and packaging line time to potentially rework the product versus recoding and marking and verifying the mark on the product correctly the first time." In mid-2009, Markem-Imaje introduced its 9000 Series line of ink-jet coding printers for primary package coding. The versatile,  heavy-duty and reliable line comprises three printers: 9020, 9030 and 9040. With single-jet and bi-jet printheads available and a wide choice of configurations, the 9000 Series is especially suitable for the food, beverage, pharmaceutical and cosmetic industries. A large selection of inks makes printing possible on just about any substrate. An intuitive user interface and easily accessible consumables mean this series is user-friendly. Nose needed here Several recent product recalls have been sparked by consumer complaints about mouldy or musty odours associated with nausea, stomach pain, vomiting and diarrhoea. Microanalytics, a subsidiary of MOCON, Inc. (Booth 6232), has developed improved approaches to identifying the source of industrial odours and can help gPure Boost Shoes

heavy-duty and reliable line comprises three printers: 9020, 9030 and 9040. With single-jet and bi-jet printheads available and a wide choice of configurations, the 9000 Series is especially suitable for the food, beverage, pharmaceutical and cosmetic industries. A large selection of inks makes printing possible on just about any substrate. An intuitive user interface and easily accessible consumables mean this series is user-friendly. Nose needed here Several recent product recalls have been sparked by consumer complaints about mouldy or musty odours associated with nausea, stomach pain, vomiting and diarrhoea. Microanalytics, a subsidiary of MOCON, Inc. (Booth 6232), has developed improved approaches to identifying the source of industrial odours and can help gPure Boost Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login