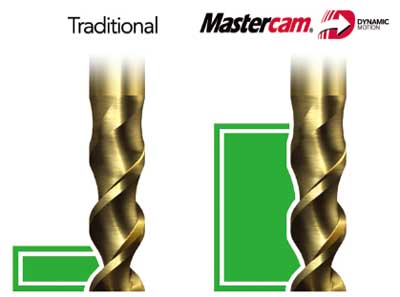

Machining steel at high temperatures using the right tools and toolpaths can result in exceptional productivity improvements. Shops machining this material should develop a close working relationship with their tool supplier to optimise their cutting strategies and compensate for excessive forces that can be generated based on material conditions ahead of the cut. Mastercam's Dynamic Motion technology is a new approach to creating toolpaths. It follows a proprietary and sophisticated set of rules that take into consideration a broad data set.

"In order to create the most efficient cutting motion possible, Dynamic toolpaths calculate more than just the areas where metal will be removed; they also take into account the changing condition of the material throughout various stages of machining," according to Mastercam.

The company added, "The toolpath has enough intelligence to look ahead, see what's coming and modify feeds, speeds, stepovers and cutting motions based on ever-changing material conditions. Significant benefits include radically shorter cycle times, less wear and breakage of tools, and less wear on machines." The basic idea is that when the stepover is 50% of the tool's width or greater, the thickness of chips being removed at any speed remains constant. When the stepover is less than 50%, the chip thickness becomes progressively smaller as the stepover decreases.

Mastercam believes that this is important knowledge, because most of the heat generated in the tool and the steel part is removed, not by coolant, but by the chips. If you decide (for good reasons) to use stepovers smaller than 50%, you will need to run at a faster feed rate to get the chip thickness back up to target so the chips will have sufficient mass to retain the heat, pull it away from the tool and the part and into the chip bin. This strategy for cutting steel not only reduces tool wear but it improves cutting efficiency.

Dynamic Motion is faster

By dramatically reducing stepovers and air cutting, Dynamic toolpaths can reduce cycle times by 25 to 75%. Dynamic Motion toolpaths ensure that your tool spends most of its time cutting at full-depth with far fewer stepdowns. This means you can cut more parts in less time.

Extend tool and machine life

Dynamic Motion uses the full flute length so users will get even wear and heat distribution resulting in fewer tool changes and less grinding that slows you down and costs money. Dynamic Motion produces consistent chip load, reducing vibration and extending the life of your machines. The looping motion eliminates abrupt directional changes, keeping your machine more accurate with less maintenance.

Cutting hard materials

Roughing hard materials can pose a challenge but Mastercam's Dynamic Motion toolpaths make it easier by ensuring even heat and load distribution throughout the cut. This even distribution prevents material surface hardening and reduces the risks of tool breakage, giving more consistent, predictable results.

"This strategy can create significant pressure increases on the tool as it becomes duller, progressively increasing the danger of breakage. This danger can be ameliorated by use of dynamic motion technology, which adjusts the tool motion based on material conditions ahead of the cut to compensate for excessive forces that can be generated," Mastercam finally said.

New Balance Popular Collection

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login