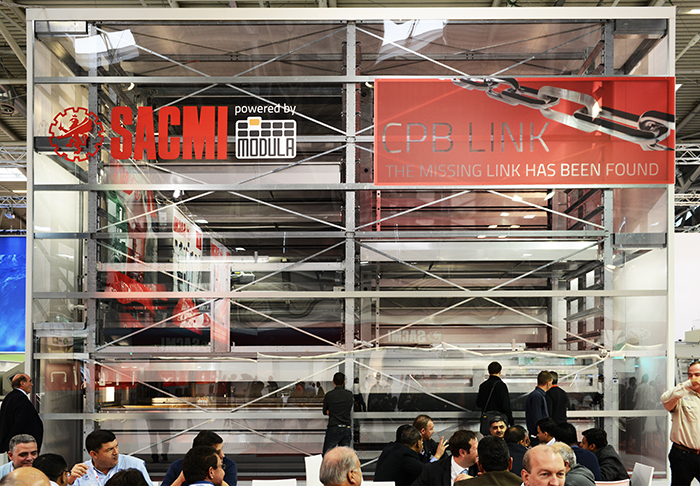

THE Sacmi CPB LINK, a new highly automated dynamic buffer integrates cap and preform production with the bottling line.

Since cap and preform storage and subsequent feeding of the bottling line become a single fully automated, integrated process, the CPB LINK offers manufacturers energy and logistics savings. It allows for smooth management of production flows and boosts hygiene-related bottling process safety, thanks to thermal and microbiological conditioning of the buffer (ultraclean environment).

The three Sacmi Group companies (Sacmi Imola, Sacmi Packaging and Sacmi Filling) collaborated in the development of this system.

“With CPB LINK, Sacmi has provided the first automatic cap and preform storage magazine to act as a link between the cap and preform production solutions and the integrated stretch-blow moulding and filling lines,” said Iacopo Bianconcini, marketing manager of the Group’s Beverage and Closures&Containers Division. “The result is the first true, complete beverage production line, integrated in terms of both process synchronisation (thanks to the storage buffer) and equipped to respond to the natural need for bottling line flexibility (for example, frequent line stops for size changeovers and changing seasonal output requirements).”

The system allows users to store preforms and caps tidily in stainless steel containers. Further advantages include complete traceability and FIFO management. The SACMI-made vertical magazine is also fire-resistant in compliance with the strictest international standards. It can provide storage volumes of up to 20 million preforms and 150 million caps. Sacmi CPB LINK allows storage capacities to be configured according to customer requirements and can be up to 41 m long and 14 m high.

According to Sacmi, a US bottled water producer has invested in this system. The result of thorough cost-benefit analysis carried out jointly by team Sacmi and the customer’s own technicians, this investment will provide the American firm with considerable savings in terms of both CO2 emissions (nearly halved with respect to the current storage system which uses laser-guided vehicles) and in terms of assured product quality thanks to a fully ultra-clean storage process that requires no chemical solvents.

Nike Mens Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login