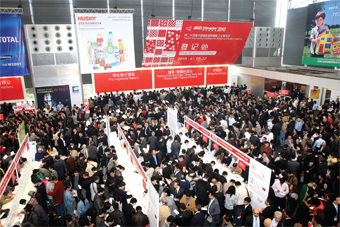

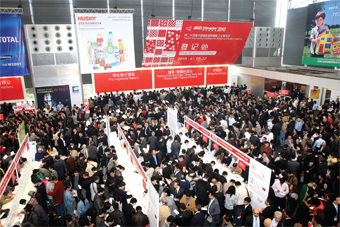

The economic growth and human welfare gains should not be achieved at the cost of environmental deterioration. Natural resources should be produced, processed and consumed in a more environmentally sustainable way. CHINAPLAS 2010, which was successfully concluded on 22 April at the Shanghai New International Expo Centre, Pudong, Shanghai, PR China, highlighted these objectives for "green plastics." The exhibition attracted over 81,435 visitors with majority being professional buyers in search of the latest chemical and raw materials as well as all kinds of plastics and rubber technologies. As Asia's No. 1 and the world's No. 3 exhibition, CHINAPLAS continues to emerge a winner in terms of the range of products exhibited by leading players in the plastics and rubber industry. Despite a dip in European attendance due largely to the volcano eruption, the number of exhibitors surged by 18% to 2,100. "China is now the No.1 producer of plastics machinery in the world. There are over 20,000 factories with production of plastics products valued at over 5 million yuan annually ($732,560) producing plastic products. The new slogan of CHINAPLAS 2010 - The Growth Engine for Your Industries - witnesses the congruent growth of this exhibition along with various industries and sectors. It injects new momentum into various industries and enables enterprises to take advantage of early opportunities in the wake of economic revival," said Mr. Stanley Chu, Chairman of the Adsale Exhibition Services Ltd, the organiser of CHINAPLAS 2010. Environment protection solutions at its best Through a series of industrial conferences, the visitors gained deeper understanding of plastics being an eco-friendly material. With real case sharing on the applications of green plastics, visitors were able to confer with leading green plastics and rubber solution providers and experts from different countries, and network with manufacturers who adopt the green technologies. Speakers from renowned exhibitors, including BASF, Bayer, DSM, Du Pont, provided rich information on green applications. The exhibition also featured a "Green Corner," which displayed the most advanced eco-friendly plastics and rubber technologies from exhibitors in order to encourage buyers to source the green exhibits and finally adoption of the green concept into their end products. Green raw materials such as polylactic acid (PLA) and bio-degradable resin and their products were the crowd's favourites. Exhibitors' Feedback

Mr. Karl-Heinz Hoefert Vice President, Service and Sales (SEA, Japan & Korea) Husky Injection Molding Systems(S) Pte LTD. Tel: +86-21 5048 4800 Fax: +86-21 5048 4900 Website:

www.husky.ca Husky demonstrated turnkey injection moulding solutions at the show. Mr. Karl-Heinz Hoefert, Vice President, said that "customers benefit from working with us. We deliver an optimised, efficient workcell with components specifically designed to work together." One of the systems introduced is HyPET 400 with 96- cavity. The High Performance Package (HPP) can run a 13.3g EcoBase™ preform at a cycle time of 7.0s. HPP is the result of refinements to the entire HyPET preform system and typically reduces cycle times by 15%, lowering the overall cost of PET packaging.

Dr. Dahai Yu President Evonik Degussa(China)Co., Ltd. Tel: +86-21 6119 1000 Fax: +86-21 6119 1428 E-mail: info@evonik.com Website:

www.evonik.com.cn Resource efficiency is a major trend that will revolutionise the global society and economy. Evonik demonstrated its innovative plastics products and solutions for resource efficiency, and shared its contribution for sustainable development. "Despite the difficult economic situation, the C

Highsnobiety Style The economic growth and human welfare gains should not be achieved at the cost of environmental deterioration. Natural resources should be produced, processed and consumed in a more environmentally sustainable way. CHINAPLAS 2010, which was successfully concluded on 22 April at the Shanghai New International Expo Centre, Pudong, Shanghai, PR China, highlighted these objectives for "green plastics." The exhibition attracted over 81,435 visitors with majority being professional buyers in search of the latest chemical and raw materials as well as all kinds of plastics and rubber technologies. As Asia's No. 1 and the world's No. 3 exhibition, CHINAPLAS continues to emerge a winner in terms of the range of products exhibited by leading players in the plastics and rubber industry. Despite a dip in European attendance due largely to the volcano eruption, the number of exhibitors surged by 18% to 2,100. "China is now the No.1 producer of plastics machinery in the world. There are over 20,000 factories with production of plastics products valued at over 5 million yuan annually ($732,560) producing plastic products. The new slogan of CHINAPLAS 2010 - The Growth Engine for Your Industries - witnesses the congruent growth of this exhibition along with various industries and sectors. It injects new momentum into various industries and enables enterprises to take advantage of early opportunities in the wake of economic revival," said Mr. Stanley Chu, Chairman of the Adsale Exhibition Services Ltd, the organiser of CHINAPLAS 2010. Environment protection solutions at its best Through a series of industrial conferences, the visitors gained deeper understanding of plastics being an eco-friendly material. With real case sharing on the applications of green plastics, visitors were able to confer with leading green plastics and rubber solution providers and experts from different countries, and network with manufacturers who adopt the green technologies. Speakers from renowned exhibitors, including BASF, Bayer, DSM, Du Pont, provided rich information on green applications. The exhibition also featured a "Green Corner," which displayed the most advanced eco-friendly plastics and rubber technologies from exhibitors in order to encourage buyers to source the green exhibits and finally adoption of the green concept into their end products. Green raw materials such as polylactic acid (PLA) and bio-degradable resin and their products were the crowd's favourites. Exhibitors' Feedback

The economic growth and human welfare gains should not be achieved at the cost of environmental deterioration. Natural resources should be produced, processed and consumed in a more environmentally sustainable way. CHINAPLAS 2010, which was successfully concluded on 22 April at the Shanghai New International Expo Centre, Pudong, Shanghai, PR China, highlighted these objectives for "green plastics." The exhibition attracted over 81,435 visitors with majority being professional buyers in search of the latest chemical and raw materials as well as all kinds of plastics and rubber technologies. As Asia's No. 1 and the world's No. 3 exhibition, CHINAPLAS continues to emerge a winner in terms of the range of products exhibited by leading players in the plastics and rubber industry. Despite a dip in European attendance due largely to the volcano eruption, the number of exhibitors surged by 18% to 2,100. "China is now the No.1 producer of plastics machinery in the world. There are over 20,000 factories with production of plastics products valued at over 5 million yuan annually ($732,560) producing plastic products. The new slogan of CHINAPLAS 2010 - The Growth Engine for Your Industries - witnesses the congruent growth of this exhibition along with various industries and sectors. It injects new momentum into various industries and enables enterprises to take advantage of early opportunities in the wake of economic revival," said Mr. Stanley Chu, Chairman of the Adsale Exhibition Services Ltd, the organiser of CHINAPLAS 2010. Environment protection solutions at its best Through a series of industrial conferences, the visitors gained deeper understanding of plastics being an eco-friendly material. With real case sharing on the applications of green plastics, visitors were able to confer with leading green plastics and rubber solution providers and experts from different countries, and network with manufacturers who adopt the green technologies. Speakers from renowned exhibitors, including BASF, Bayer, DSM, Du Pont, provided rich information on green applications. The exhibition also featured a "Green Corner," which displayed the most advanced eco-friendly plastics and rubber technologies from exhibitors in order to encourage buyers to source the green exhibits and finally adoption of the green concept into their end products. Green raw materials such as polylactic acid (PLA) and bio-degradable resin and their products were the crowd's favourites. Exhibitors' Feedback  Mr. Karl-Heinz Hoefert Vice President, Service and Sales (SEA, Japan & Korea) Husky Injection Molding Systems(S) Pte LTD. Tel: +86-21 5048 4800 Fax: +86-21 5048 4900 Website: www.husky.ca Husky demonstrated turnkey injection moulding solutions at the show. Mr. Karl-Heinz Hoefert, Vice President, said that "customers benefit from working with us. We deliver an optimised, efficient workcell with components specifically designed to work together." One of the systems introduced is HyPET 400 with 96- cavity. The High Performance Package (HPP) can run a 13.3g EcoBase™ preform at a cycle time of 7.0s. HPP is the result of refinements to the entire HyPET preform system and typically reduces cycle times by 15%, lowering the overall cost of PET packaging.

Mr. Karl-Heinz Hoefert Vice President, Service and Sales (SEA, Japan & Korea) Husky Injection Molding Systems(S) Pte LTD. Tel: +86-21 5048 4800 Fax: +86-21 5048 4900 Website: www.husky.ca Husky demonstrated turnkey injection moulding solutions at the show. Mr. Karl-Heinz Hoefert, Vice President, said that "customers benefit from working with us. We deliver an optimised, efficient workcell with components specifically designed to work together." One of the systems introduced is HyPET 400 with 96- cavity. The High Performance Package (HPP) can run a 13.3g EcoBase™ preform at a cycle time of 7.0s. HPP is the result of refinements to the entire HyPET preform system and typically reduces cycle times by 15%, lowering the overall cost of PET packaging. Dr. Dahai Yu President Evonik Degussa(China)Co., Ltd. Tel: +86-21 6119 1000 Fax: +86-21 6119 1428 E-mail: info@evonik.com Website: www.evonik.com.cn Resource efficiency is a major trend that will revolutionise the global society and economy. Evonik demonstrated its innovative plastics products and solutions for resource efficiency, and shared its contribution for sustainable development. "Despite the difficult economic situation, the CHighsnobiety Style

Dr. Dahai Yu President Evonik Degussa(China)Co., Ltd. Tel: +86-21 6119 1000 Fax: +86-21 6119 1428 E-mail: info@evonik.com Website: www.evonik.com.cn Resource efficiency is a major trend that will revolutionise the global society and economy. Evonik demonstrated its innovative plastics products and solutions for resource efficiency, and shared its contribution for sustainable development. "Despite the difficult economic situation, the CHighsnobiety Style

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login