Siemens PLM Software jointly exhibited its latest 3D digital product development innovation together with its partners, Material Automation (Thailand) Co. Ltd (MAT) and Design Through Acceleration Co. Ltd at the Intermold Thailand 2014.

International Metalworking News for Asia interviewed both MAT and DTA, gathering enough information for all software enthusiast out there who are keen for a specific product development that simplifies the entire industrial design process, from the simplest process to highly complex products. The NX and Solid Edge applications launched at the show aims to accelerate design, engineering, manufacturing processes as well as speed to market while minimising production errors.

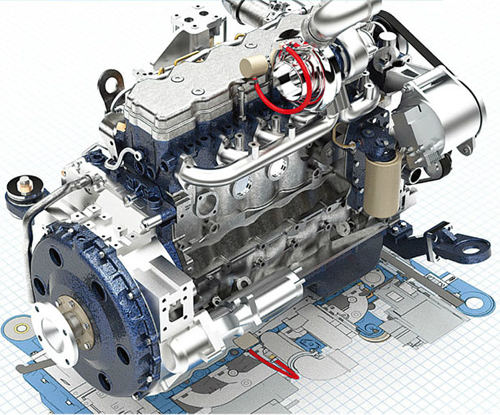

NX liberates complex design processes

Material Automation (Thailand), Siemens associate since 2003, joined Intermold Thailand 2014 for first time ever, with a view to presenting Siemens PLM Software and the Teamcenter software for systematic data management solutions targeting the tooling & fixture industry.

“Most of our customers are in the automotive industry which requires complex and highly detailed designs. Data files relating to various automotive parts also need to be dispatched to and inputed from various parts of the world, hence the importance of standardisation. Siemens’ software has been recognised as a core tool for industrial design and data file dispatches which can be efficiently coordinated in line with the requirements of car manufacturing headquarters,” said Mr. Santirat Kirdpoke, Assistant Manager, MAT.

NX design software enables CAD/CAM/CAE as well as complex analytical applications, Industrial Design and Simulation. It is especially suited to all manufacturing design processes including components & parts, packaging, mechanical, electromechanical, tooling & fixture, etc.

“You can use NX software to design all kinds of products – a tool or any kind of machinery. NX offers parameters enable us to revise our designs easily. This feature differentiates NX from other software in the market for complex design processes that include production, Data Engineering and Data Security. In addition, Siemens has also developed NX by products, namely, Technomatix and Teamcenter which go even further to integrate NX designs into production processes, Data Engineering and Data Security.”

Technomatix which focuses on Planning, Simulation & Production confirms whether designs are correct, minimises actual production errors, and identifies problems that may occur during the production process. Simulation increases accuracy by 80% while the remaining 20% probability of errors cannot be foreseen. Without simulation, the accuracy rate would be lowered to 50% - hence the entire design may need to be revised. Simulation is therefore pre-requisite for complex design projects if we aim to minimise production errors, maximise productivity and speed to market.

Representing the core component of Data Engineering and Data Security Data, Teamcenter entitles data access, manages data at every stage of the process and enables internal communication as well as communication with suppliers and customers. User organisation can allow suppliers or customers to access data, thereby ensuring that finished products perfectly correspond to customer needs.

Recognising its unique advantages and ability to fully integrate CAD, CAM and CAE software starting from design through to production and delivery of finished product, NX and Technomatix are applied worldwide not only in the automotive industry but also by other manufacturing plants.

Citing local customer experience and response, ISUZU is currently using Siemens software innovation to handle communications between HQ and producers of components & parts. NX software and experienced support staff present a perfect solution for minimizing errors and maximising productivity. This is the reason why ISUZU has selected NX software.

Efficient and user friendly

Reflecting the slogan “Solid Edge Design Better”, Solid Edge software which comes under Siemens’ PLM umbrella enables 2D Drafting and comprehensive 3D capability that is not only efficient and user friendly and also covers Assembly and Simulation. This software has won widespread recognition by designers in various industries worldwide, including automotive manufacturers, industrial machinery & printers, producers, electromechanical appliances, furniture, among others.

Mr. Kamol Tanakanockchai, General Manager, Design Through Acceleration, another Siemens associate in Thailand who also participated in Intermold Thailand, disclosed that the latest version of Solid Edge ST7 launched in Thailand in July2014 offers upgraded interface which accelerates work procedures and 3D prototyping while allowing work sheets to unfold for the purpose of forming and sizing of sheet metal and other work materials.

Solid Edge has a distinctive feature called Synchronous Technology which enables direct design creation and revision, conveniently runs on Windows as well as Surface Pro. This is probably the first software that can run and be applied perfectly on Surface. The software is also smart enough to pull files from other programs and make continuous modifications on the spot.” he added.

“99% of customers who have actually used this design tool exclaimed “Wow! We have never before seen this type software that can import data or files in order to run and directly modify 3D designs. There is no historical record of installing imported design stages and directly implement design revisions.”

Solid Edge’s unique strength lies in Accelerated design, faster revision, ability to use files from other programs, pull 2D or 3D data for better imported re-use to help companies design better.

“Solid Edge’s world class ability under Siemens brand umbrella outperforms other software in the marketplace in terms of price to efficiency ratio. Solid Edge will always be the first choice for customers whom we perceive as our future potential, namely, machinery manufacturers, food processing machines, agricultural tools & machinery, small & medium sized mould producers. These potential customers can afford software investments that are reasonably priced.

“In summary, the macro picture of Thailand’s software industry has improved despite oversupply of sellers in the market. Our selling point lies in the fact that we are the top choice for the majority of customers who have confidence in our product and our brand name. Every member of our strong support team has also been endorsed by Siemens.” said Mr. Kamol.

Buty dziecięce

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login