There are two ways to create microvias: conventional mechanical drilling and a laser-based process. The major advantage of mechanical bits is that the complex mix of materials presents no problems. On the downside, they cannot achieve diameters less than one-tenth of a millimeter, they can drill only about 20 vias per second, and they wear out within minutes.

That is why manufacturers early on began using UV and CO2 lasers. UV nanosecond lasers can be focused so narrowly that they are even able to create 50 micron holes. Their output power is low, however, and the glass fiber reinforced plastics found in many PCBs can cause problems. CO2 lasers, on the other hand, can create far more than one thousand microvias per second, but the vias cannot be less than 75 microns in diameter. What's more, the highly reflective copper on and between the layers of plastic represents a natural barrier to light. As a consequence, these two types of lasers are often used together in processing operations, alternating with each other to cut through alternating plastic and copper layers.

Ultrashort pulse lasers do away with these limitations because they simply change the rules governing energy absorption. With their extremely energy-intense, ultrashort laser flashes, they force the molecules or atoms in the material to absorb more than one photon at a time. This multiphoton absorption means that the impinging laser light is absorbed in an almost ideal fashion. In a few trillionths of a second, the material “devours” the pulse's energy without having enough time to spread more than a miniscule fraction in the form of heat. The material sublimes and vaporizes immediately, regardless of whether it be plastic, glass, copper or a ceramic.

Percussion drilling

Percussion laser drilling is the technique normally employed when the laser is used to create microvias. Here the laser will apply multiple pulses to the same spot. It “hammers” its way a bit deeper into the material with each pulse, with the diameter of the finished passageway corresponding to the size of the focus spot. In this way, thousands of holes can be drilled very quickly using high pulse frequency and high pulse energy.

The picosecond lasers in the TruMicro Series, when compared with CO2 lasers, achieve similar or even greater processing speeds. Working with circuit boards 200 microns thick, finished with copper on each face, these ultrashort pulse lasers with a mean power of 50 watts can drill 1,200 through holes per second. When mean power is boosted to 100 watts, this number can rise to as much as 3,000. Here the vias are drilled directly through the copper layer without any need for additional layers of varnish to promote absorption. In addition, they achieve a diameter of just 30 microns.

Great demands in terms of precision can also be satisfied. If the mechanical system is sufficiently precise, the holes will deviate from the ideal position by no more than 10 microns; they will reach exactly to the surface of the conductive strip below.

A question of depth

When using CO2 lasers, exact control of the depth is relatively simple. The copper's braking action, otherwise an interfering factor, acts as an automatic stop. Otherwise it would be almost impossible to drill blind holes. This is because the distribution of intensity within the beam would basically create a conical hole.

The ultrashort pulses do not exhibit this automatic stopping effect. This is offset by the so-called “top hat” DOE – diffractive optical element, which changes the beam's intensity profile and spreads its power more uniformly across its diameter. As a result, the beam uniformly “digs” the hole into the material, with energy spread across the entire base of the hole.

Since the rate of advance into the material, for each individual pulse, is relatively slight and since this value is known for all the materials that might be encountered, it is in theory sufficient just to count the pulses so as to stop the laser at the right depth. And that actually does work for the TruMicro lasers, since the double feedback loop control developed by TRUMPF monitors each and every picosecond pulse and keeps the output and pulse energy exactly at the needed level, irrespective of any external influences.

Trepanning

Trepanning is the other basic drilling process. The optical elements cause the focus spot to circle around the hole's centreline. In the past, trepanning was used when working circuit boards as a makeshift solution whenever nanosecond UV lasers were to break through the copper layer for the CO2 laser.

During trepanning, the focus rotates around the hole's centreline and removes material as it does so.

When compared with nanosecond UV lasers, the TruMicro laser trepans about twice as fast – at a rate of some 40 blind holes per second. And this limit is imposed only by the deflection technology currently available, not by the laser itself. For the ultrashort pulse laser, trepanning is no longer an emergency workaround but instead an expansion of the available options.

The process helps to create every conceivable penetration through a circuit board – from extremely fine microvias through to round holes or slots to accommodate clamps or screws. And since the laser is at work anyhow, it can go ahead and cut out any openings and trim the edges of the panel to shape.

A tool for the future

High-performance ultrashort pulse lasers suitable for industrial use are a new and highly promising tool. This is a fact than earned the cooperative effort, from which the TRUMPF ultrashort pulse laser stems, a nomination to receive the Future Prize awarded by Germany's Federal President.

The first systems capable of drilling printed circuit boards have come onto the market in the meantime. They work with the current generation of TruMicro picosecond lasers, proven in industrial operations. These units provide mean output of 100 watts and peak pulse power of 40 megawatts. Beam sources with mean output of 150 watts are already on the market, while the TruMicro 5000 Femto Edition represents the first industrial beam source to deliver pulses in the femtosecond range. The future of the printed circuit board has just begun.

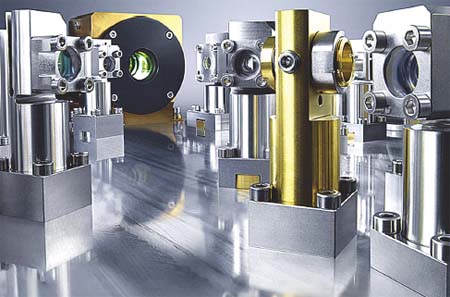

The short- and ultra-short pulsed lasers of the TruMicro product portfolio enable micro-processing with an optimum combination of quality, productivity, and profitability

Nike Air Jordan 1 Mens

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login