When a snack food producer began experiencing repeat failures of the bearings on its cutter lines, a switch to NSK Life-Lube® housed bearing units delivered savings in excess of €130,000, primarily thanks to the elimination of lost production.

Production uptime is vital in process industries such as food and beverage. Many companies in this sector operate a business model based on high-volume throughput and narrow profit margins in order to remain competitive in a fierce marketplace. Any line stoppages can therefore have a highly detrimental effect on bottom-line profitability.

Cutter lines fulfil a process-critical operation at food plants. (Photo: alterfalter I Shutterstock)

A case in point is a producer of snack foods that began experiencing frequent bearing failures on its process-critical cutter lines. To resolve the situation as quickly as possible, the plant turned to the expertise of NSK.

As part of NSK’s Added Value Programme, AIP, a process map survey was conducted on site encompassing an investigation of the failed bearings by NSK’s experienced engineering team. This activity identified grease expulsion as the problem due to line wash-down procedures. The issue was prompting bearing replacement every six weeks during routine planned maintenance to help prevent unplanned stoppages. However, failures sometimes occurred before scheduled maintenance, resulting in the loss of valuable production time, the cost of which ran into six figures a year.

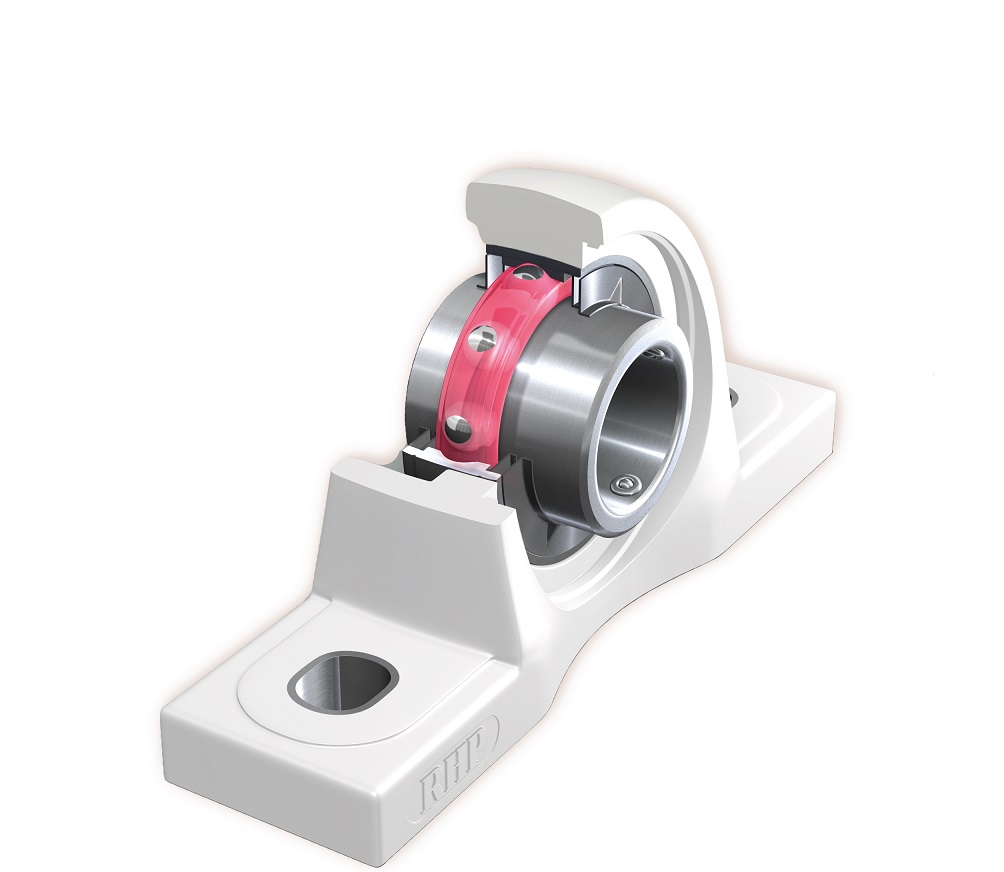

Cutaway of an NSK Life-Lube® housed bearing unit showing the Molded-Oil insert. (Photo: NSK)

NSK proposed replacing the incumbent bearings with the company’s Life-Lube® housed bearing units. The Life-Lube® series combines the corrosion-resistant properties of NSK’s Silver-Lube® thermoplastic (paint-free) housings with the excellent sealing and lubricating properties of the company’s Molded-Oil inserts, which feature solid lubricant. This proprietary material consists of lubricant and a polyolefin resin with an affinity for oil. Grease releases steadily and continuously over a long period, keeping the operating environment clean as there is no need for replenishment and no lubricant can escape.

Life-Lube® units are specifically for use in applications where contact with water and process fluids is unavoidable, and where long lubricant life is necessary. NSK therefore identified Life-Lube® as the optimal solution for the snack food plant and its detergent based wash-down procedures.

NSK proposed a trial of Life-Lube® housed bearing units on one of three cutter lines at the snack food plant, the monitoring of which would determine suitability. After one year, the bearings were still performing well with no failures, eliminating production downtime entirely. Alongside far lower costs for parts and maintenance labour, the plant is seeing impressive annual savings of €134,478. Thanks to this success, NSK Life-Lube® housed bearing units now populate the snack food plant’s other two cutter lines.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login