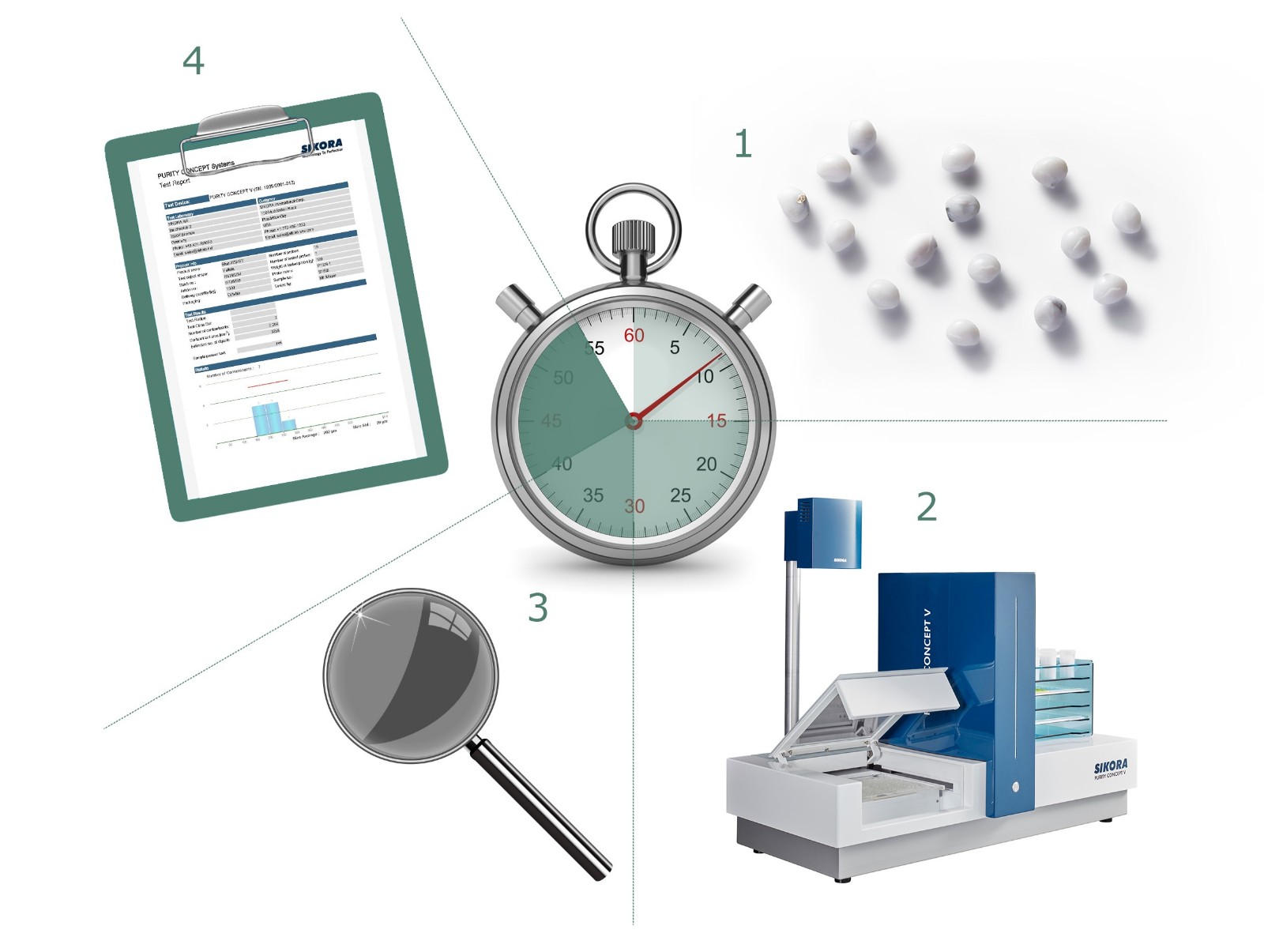

Offline sample inspections are nowadays used as standard during the quality control of plastic pellets. With the PURITY CONCEPT V, SIKORA offers a semi-automated innovative laboratory testing device, which convinces especially by its intuitive operation and fast, precise analysis.

1 minute or even the duration in which a fully automatic coffee machine conjures up a delicious latte macchiato – the PURITY CONCEPT V does not need longer to generate a complete evaluation including test certificate. The operator places the sample material to be tested on the sample tray and presses the start button. It doesn't matter whether plastic pellets, flakes or test plates as well as black specks, color contamination, white spots or discolorations shall be examined– all no problem for the PURITY CONCEPT V.

The system does the rest by itself: The material is scanned, analyzed and contaminants as small as 50 µm are detected. The test certificate, generated by mouse click, contains all information about size, number and type of contamination, as well as an image gallery of all detected contaminants. Documentation and material release have never been so easy.

All detected impurities are marked on the scan image and highlighted in parallel on the sample tray. The operator can zoom in and out of the monitor image as desired and click on individual contaminants. These are localized on the sample tray by crosshairs so that contamination can be separated easily, e.g. for further examination. Even afterwards, the operator can re-read the data material and repeat the analysis as often as he wishes with changing parameters. This ensures reliable results.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login