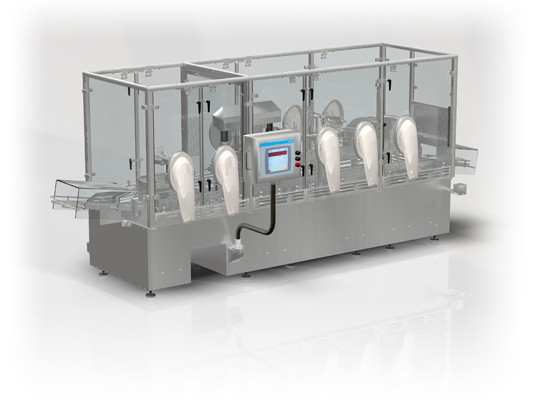

OPTIMA Pharma will launch its Optima H4 filling and closing machine Interphex 2015 in Javits Center, New York from April 21 to 23.

Designed for a wide range of applications, the Optima H4 features simple operation, ease of access, reliability, flexibility, and compact design. Its standardized architecture allows for the premanufacture of modules, which in turn translates to time and cost benefits. The nested vials, syringes, and cartridges are all processed.

The filling machine can accommodate an installed robot to save space and handle functions such as opening the tubs and removing the Tyvek papers. Semi-automated systems could also be integrated.

The standardized machine baseplate can accommodate systems, whether oRABS, cRABS, or isolators, at low cost. A ten-position system is used for filling. Rotary pistion pumps and asperistaltic or time-pressure filling systems can be added any time for simple format changes and filling flexibility. In-process controls (IPC) and vacuum filling and vacuum stopper insertion can be upgraded and supplemented without modifications to the machine baseplate.

The Optima H4’s transport system ensures even and careful handling of the containers. It supports a high output rate of up to 24,000 objects per hour, expandable to 36,000 objects per hour with retrofitting.

Optima Pharma will also showcase its know-how in further technologies at Interphex 2015. Besides filling and closing machines, the company offers finely adjusted interacting process technology systems in its washing machines, sterilizing tunnels, isolators, and further containment systems. It also supplies pharmaceutical freeze drying and robotics for product handling.

Vêtements et équipement Lifestyle pour Femme

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login