The beverage market is constantly changing. As the global population grows, demand for consumer goods, including liquid food products, is expected to increase 50% by 2030. Consumers today have wider tastes and appreciate a twist on traditional flavours. They are also becoming increasingly more health conscious, demanding beverages with “better-for-you” attributes. These consumers are interested in safe, all-natural products without preservatives, and are gradually stressing greater transparency of where products come from and how they are made. At the same time, consumers want products that fit their lifestyle and offer the convenience of single-serve "on-the-go" consumption or bulk-buying.

For manufacturers of containers, the challenge is to meet all the requirements and restrictions of the market, and generate profit at the same time. In this aspect, Sidel has launched the Sidel Matrix that enables manufacturers to meet market demands with a highly changeable production line. The system provides manufacturers of beverage products to offer their customers a wide range of products to choose from as Sidel Matrix is more than accommodating, as it's capable of multiplying the number of possible configurations to match specific needs in terms of beverage, bottle size or output. As a highly changeable production line, Sidel Matrix is scalable, so manufacturers can easily and frequently adapt their production to consumer needs and what the market demands.

Based on proven blowing, filling and labeling technology, Sidel Matrix has the line flexibility to handle various types of beverages, whatever the recipe or bottle format. For example, with three sizes of blowing stations, manufacturers are given full freedom of shape and the ability to process single-serve (up to 750ml), multi-serve (up to 2L) or extended family (up to 3.5L) bottles.

Additionally, the fillers provide well-defined module interfaces in order to make changes without impact, and the labellers can handle various kinds of materials as well as bottles of even the lightest weights. As an option, Sidel Matrix offers automatic format and product changeovers to reduce downtime.

The Sidel Matrix solution includes blowers, fillers, labellers, and the Sidel Matrix Combi, an integrated blow-fill-cap solution that Sidel introduced and has constantly improved over the last 16 years. Designed with the future in mind, this system of standalone equipment is future-proof, meaning it can easily incorporate advances in technology and market developments. Options, upgrades and line conversions are also available to suit the production needs.

Fast changeover and minimal downtime

There's no time for downtime in an industry of constant uptime. Based on leading expertise of the complete line from a supplier with the largest installed base worldwide, Sidel Matrix offers some of the highest speed and overall equipment efficiency (OEE) in the industry with optimised uptime. However, it's not just speed that accounts to its efficiency – it's a reduction of costly downtime and better control of the production line as a whole.

Built with grease-free components and fewer mechanical parts, the robust and reliable Sidel Matrix requires significantly less maintenance. The blower maintenance time is limited to a very low percentage of the running time, with fillers designed to reduce maintenance requirements with high efficiency, and the maintenance required on the labelers has been reduced by approximately 40%. However, when any of the machines do require maintenance, Sidel provides services, such as preventative maintenance, 24/7-hotline support and proactive diagnostic visits.

Downtime is further reduced with fast, optimised changeovers, and the entire Sidel Matrix line requires just 2 operators. For Sidel Matrix Combi, one simple and logical human machine interface (HMI) system allows operator to manage operations without further manual intervention while improving data exchange, control and assistance. In addition, it enables fast changeovers due to positive neck handling from pre-form to capped bottle. Ultimately, the performance of all Sidel Matrix solutions is enforced through training programmes.

Material savings ensured Proven Sidel Matrix improves cost-efficiency by requiring less energy, air, chemicals and water while enabling ultra light-weighted bottles. For example, the Sidel Matrix blowers require less energy consumption with the Ecoven using up to 45% less power, and by reducing the heating time by about 15%, compared with previous generation of blowers – all while ensuring excellent material distribution.

Regarding air consumption in the blower, savings of up to 35% depending on the requirements of the compressor can be achieved. Also, the fillers reduce energy usage by up to 30% using servomotors instead of traditional drive systems, and the labellers cut energy consumption by up to 30% as all moving parts are now directly connected to the motor. The Sidel Matrix blowers also enable reduction of bottle weight, while maintaining bottle shape and strength, due to embedded high process capability and control. In addition, the new labellers allow the use of labels that are one-third thinner. Lighter products will ultimately decrease your material spending, and even reduce transportation costs.

Sidel is a leading global provider of PET solutions for liquid packaging. Headquartered in Switzerland, the company operates production sites in 13 countries and 30,000 machines installed in more than 190 nations worldwide.

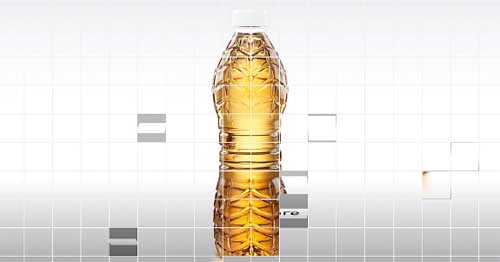

Sidel Matrix enables the production of lightweight bottles.

Shop Women's Sneakers by Brand

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login