EMO 2023 will be the setting for the official unveiling of the ROLLOMATIC SMART FACTORY, a proven concept developed over the years to meet the new challenges faced by tool manufacturers. The new LASERSMART®810XL, designed for machining large-diameter tools, will also be in the spotlight in Hannover, as will the high-performance LEAN grinding solutions from the SMART AUTONOMOUS GRINDING programme and the STRAUSAK solution for resharpening and special tools production.

ROLLOMATIC SMART FACTORY

Customers are at the heart of ROLLOMATIC’s philosophy. This is also the case when it comes to thinking ahead and being proactive in offering the best manufacturing solutions. This philosophy has led the company to develop the especially effective SMART FACTORY programme. It provides a new way to organise production resources using information technology, machine communication systems and robotics. ROLLOMATIC’s extensive experience in the above-mentioned fields enables it to support customers throughout the SMART FACTORY process. Cutting tool manufacturers want more autonomous machines in order to cut production times without skimping on operational quality. ROLLOMATIC has mastered the production stages, is constantly optimising processes and, above all, understands what customers need. ROLLOMATIC SMART FACTORY solutions can satisfy those needs.

LASER SOLUTIONS

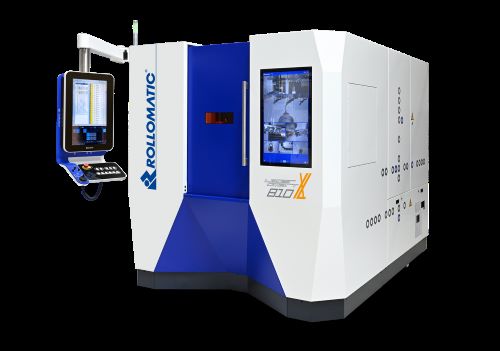

ROLLOMATIC’s laser solutions are the most effective offerings on the market for cutting ultra-hard materials and 3D machining. With the new LASERSMART®810XL, specifically designed for machining large-diameter tools, ROLLOMATIC covers a very wide range of possible applications. Designed for the production of cutting tools in ultra-hard materials and featuring 6 simultaneously interpolated axes, the new, ultra-compact LASERSMART®810XL has been designed to machine tools up to 300 mm in diameter, 350 mm in length and weighing up to 15 kg. An automatic loader with a capacity of 30 parts is included as standard. The LASERSMART®810XL is the perfect solution for machining ultra-hard tools used in the automotive, aerospace and woodworking industries. The LASERSMART®510 femto offers unlimited machining possibilities and maximises productivity, precision and surface quality. In addition to PCD, P-CBN, CVD, MCD and natural diamond, the LASERSMART®510 femto can machine ceramics, carbide, sapphire, glass and new combinations of materials. Thanks to this revolutionary machine, users can achieve results that set a new standard for machining ultra-hard materials.

ROLLOMATIC LEAN PHILOSOPHY

The LEAN philosophy has anchored ROLLOMATIC for many years. It forms an integral part of our corporate culture and permeates the design of all our products. Reducing lead times, non-productive and non-value added time, and optimising process management are just some of the challenges facing today’s machine fleets. The GRINDSMART®660XW is a perfect illustration of what LEAN can do. With the GRINDSMART®830XW machine, ROLLOMATIC can now offer grinding solutions for the entire range of micro and macro tools.

STRAUSAK

STRAUSAK, which celebrates its 100th anniversary this year, joined the ROLLOMATIC Group in 2011. As part of the group, it helped expand the range of sharpening solutions for cutting tools, as evidenced by STRAUSAK ONE, its flagship model. This latest-generation 5-axis grinding machine has been designed for the production of special tools, inserts or resharpening. Adapted to unpredictable events, the STRAUSAK ONE combines precision and efficiency. Possibilities are endless thanks to its easy programming on Numroto.

ROLLOMATIC SERVICES

ROLLOMATIC has carried out a complete overhaul of its digital customer portal. MyROLLOMATIC brings together all the services that enable users to increase efficiency and speed. It also includes new features. The intuitive dashboard provides access to all machine documentation, software and the ROLLOMATIC LEARNING CENTER. It offers an easy overview of the production status, via RMonitor, and of the history of service calls on machines. ROLLOMATIC customers can also issue a support ticket directly if they need to. As for the ROLLOMATIC LEARNING CENTER, a teaching platform that was set up a few years ago as a knowledge base of ROLLOMATIC’s expertise, it is constantly being optimised with the aim of providing tools that will quickly make operators autonomous. ROLLOMATIC LEARNING CENTER now offers over 200 hours of training in 6 different languages. Different levels are offered, from basic to expert, depending on the production goals set by the customer. Today, ROLLOMATIC LEARNING CENTER offers new courses, tutorials, access to documentation and team management features for production managers.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login