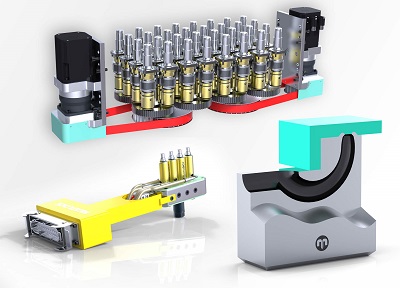

i-mold of Michelstadt, Germany augmented its range of system solutions for efficiency improvement in mold construction. The company offers a wide range of differently designed tunnel gate inserts for cold runner injection molds permitting particularly compact mold design as well as considerable time and cost savings for mold installation and maintenance.

The range of tunnel gate inserts features four different types, each being available in several different sizes, manufactured from highly wear-resistant steel and readily exchangeable when the need arises. They are suitable for all unreinforced and for almost all reinforced polymers. Possible shot weights range from less than 1 g to over 1,000 g depending on the type of insert and the melt viscosity. The TG types feature a tightly curved runner and are hence particularly space-saving. They may also be used for sub-gating behind an all-around rim or for internal gating above the parting line. Types S1 and S2 (with or without machining allowance) have also proved to be ideal for submarine gating, while the contourable inserts SGC and TGC have been designed for side or submarine gating with large contour increments. The TPS straight standard sub-gates feature an integrated dead-end recess which reduces shear stress and loss of pressure in the melt.

i-mold offers a wide range of tunnel gate inserts for cold runner injection molds

Specialty molds for high product quality

In the area of beverage closure, another company, Husky, has optimized its mold production system for high-speed, high-cavitation, high-volume applications, integrating mold production seamlessly with its beverage closure products.

Husky’s beverage closure mold design improves productivity and maximizes uptime by eliminating unnecessary stoppages and allowing for quick and easy maintenance. The mold also incorporates specific features to provide easy set-up and mold longevity while eliminating the need for sensors to monitor vulnerable components. Husky beverage closure molds offer innovative and robust one-piece slide design to optimize cycle time; mold ID for process recall and real-time maintenance information for enhanced flexibility (optional); faster installation with quick connections on the cooling manifold to improve uptime; and internal slide actuation to prevent collisions and resulting damage

In the area of specialty closure molds, Husky KTW™ molds are supported by 30 years of technical expertise and innovation. The KTW™ closure molds are offered to specialty closure customers, individually or as part of a complete solution. KTW molds are optimized for high speed, high cavitation, high volume applications and integrate seamlessly with Husky’s closure systems. A result of deep technical expertise and innovation, KTW molds are developed with the goal of delivering the highest value by providing industry-leading part quality, productivity and reliability.

KTW molds offer innovative technical solutions, including: multi-component technology; in-mold assembly and in-mold closing; cube, single-face or stack design; unique EASYcube™ technology yielding industry-leading reliability; highest levels of part quality and repeatability; cycle time optimization; weight optimization for existing closures and new designs; and flexibility and compatibility with competing specialty closure products

By providing additional services, such as flow simulation analysis, prototyping and mold testing, Husky ensures its specialty closure solutions deliver the results expected by the customers.

In the medical field, the Schöttli® Medical Molds offers precise, high-quality medical molding equipment and tooling, Schöttli® molds are designed for high performance with leading-edge reliability, efficiency and durability. Schöttli® medical molds are manufactured for the production of function- and weight-optimized medical and laboratory parts, with a strict focus on quality.

Schöttli® molds feature: high levels of part quality and repeatability with lowest risk; cycle time optimization for lowest total cost of ownership; flexibility and compatibility with other Husky products; stack mold technology for maximum productivity. The Schöttli® quick change system also minimizes downtime and increases availability of the mold. The compact cluster design – lateral, symmetrical gating allows for significant material savings with increased product quality on confined space, while the electric ejector drives make it suitable for cleanroom molding and stack molds.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login