The injection moulding process requires equipment that will not only enhance productivity, but ensure product quality. Innovative auxiliary equipment nowadays are designed towards sustainability and optimizing the whole process to ensure cost reduction through reduced material wastage while raising the level of quality.

The T-EVAC system is the flagship in the range of innovative material degassing stations from the German TARTLER Group. It supports quality-enhancing, resource-saving and cost-reducing processing methods across all modern synthetic resin processes. With HRScool Evo, hot runner specialist Oerlikon HRSflow has developed a system in which the hydraulic cylinder that positions the pin does not require separate, active water cooling.

T-EVAC degassing system sets standards in material conditioning

Whether the requirement is for vacuum infusion or wet pressing, direct infusion or resin transfer moulding (RTM) – the TARTLER Group degassing stations can meanwhile be used in almost all technologies of modern synthetic resin processing. Also, users of other processes in which liquid and pasty media circulate have now also discovered the advantages of these innovative system solutions. At the moment, it is primarily the T-EVAC type evacuation system, which is mostly customised, that has proven to be a pioneering option for quality-enhancing, resource-saving and cost-reducing material conditioning. Numerous synthetic resin processors now use them as a preliminary stage in their dosing and mixing processes, thereby opening up further scope for improving the mixing quality, material efficiency and product quality.

The T-EVAC is particularly popular in vacuum infusion technology. As in numerous other synthetic resin processing methods, one crucial question is always in the mind of plant operators, product developers and quality optimizers: How can the homogeneity of the material mixtures consisting of different components (resins, hardeners, additives, etc.) be significantly improved? Since this is precisely the focus of Tartler degassing systems, they make a decisive contribution to the sof high-quality shaping, application or coating results.

The functionality of the T-EVAC can be illustrated using the example of a synthetic resin processing method where the TARTLER system is currently encountering growing interest: pultrusion technology. In industrial practice, this technology is now a multi-stage process for the production of lightweight profiles or weight-saving moulded parts made of carbon or glass fibre reinforced plastic. Passing a fibre reinforcement – fleece, mat or another knitted fabric – through a bath or a mould with a matrix of liquid polyurethane or epoxy resin and various additives is usually one of the first processing steps. The quality of the mixture of resins and additives is of great relevance for the successful cross-linking of the CFRP or GFRP fabric with the matrix. To be on the safe side at this point, the first T-EVAC degassing stations are already being used in pultrusion technology. As before, users are using the opportunity to positively influence the quality of the mixture immediately before application – for example by controlling the dosing/mixing system and selecting the mixing heads and mixing spirals (all of this is also part of the TARTLER portfolio). With the T-EVAC, however, the operators of the pultrusion systems tap into additional potential for process optimization and improvement of the product quality. The reason for this: With a vacuum of <5 mbar (abs.), the T-EVAC removes all air and moisture from the resins and hardeners before processing.

With the components preconditioned in this way, the dosing/mixing system can then create mixtures of high homogeneity reliably and with repeatability, with which high-quality composite-technical results can be reliably achieved in the subsequent pultrusion. Many fillers (e.g. zeolites) previously required in pultrusion technology, which are intended to bind moisture in the resin in order to prevent unwanted reactions, can be partially or even completely omitted. Since the use of such fillers is unpopular anyway – they often act as disruptive factors in fiber impregnation – this also means a simplification and optimization of the process.

As standard, the T-EVAC has a PLC control from Siemens (7-inch HMI screen), is primarily designed for the conditioning of epoxy and polyurethane resins and achieves a degassing capacity of up to 1,000 l/h. In addition, it is basically available in two versions: As a central offline station, at which several dosing/mixing systems can be “filled up” with the degassed components; and as an inline module that can be integrated into a dosing/mixing system. The basic equipment of the T- EVAC includes an automatic vacuum pump protection system and an automatically controlled water heating system with heat recovery. Optionally, there is an automatic water-cooling system, an MX feed system with Kamlok connection for 1,200-litre IBCs and a vacuum buffer tank with a capacity of 1,000 liters. In its role as a special machine builder, TARTLER then takes care of the coordination with the individual process requirements of the customer and all other technical adjustments. As a result, the customer always receives a complete solution tailored to their needs.

TARTLER developed the T-EVAC to offer users in almost all areas of synthetic resin processing an additional tool with which they can decisively optimize their application, coating and shaping processes as well as the quality of their products. The improvements achieved through the use of the vacuum degassing station can be measured and verified and documented in numerous customer applications by TARTLER.

Actuator without active cooling reduces energy consumption

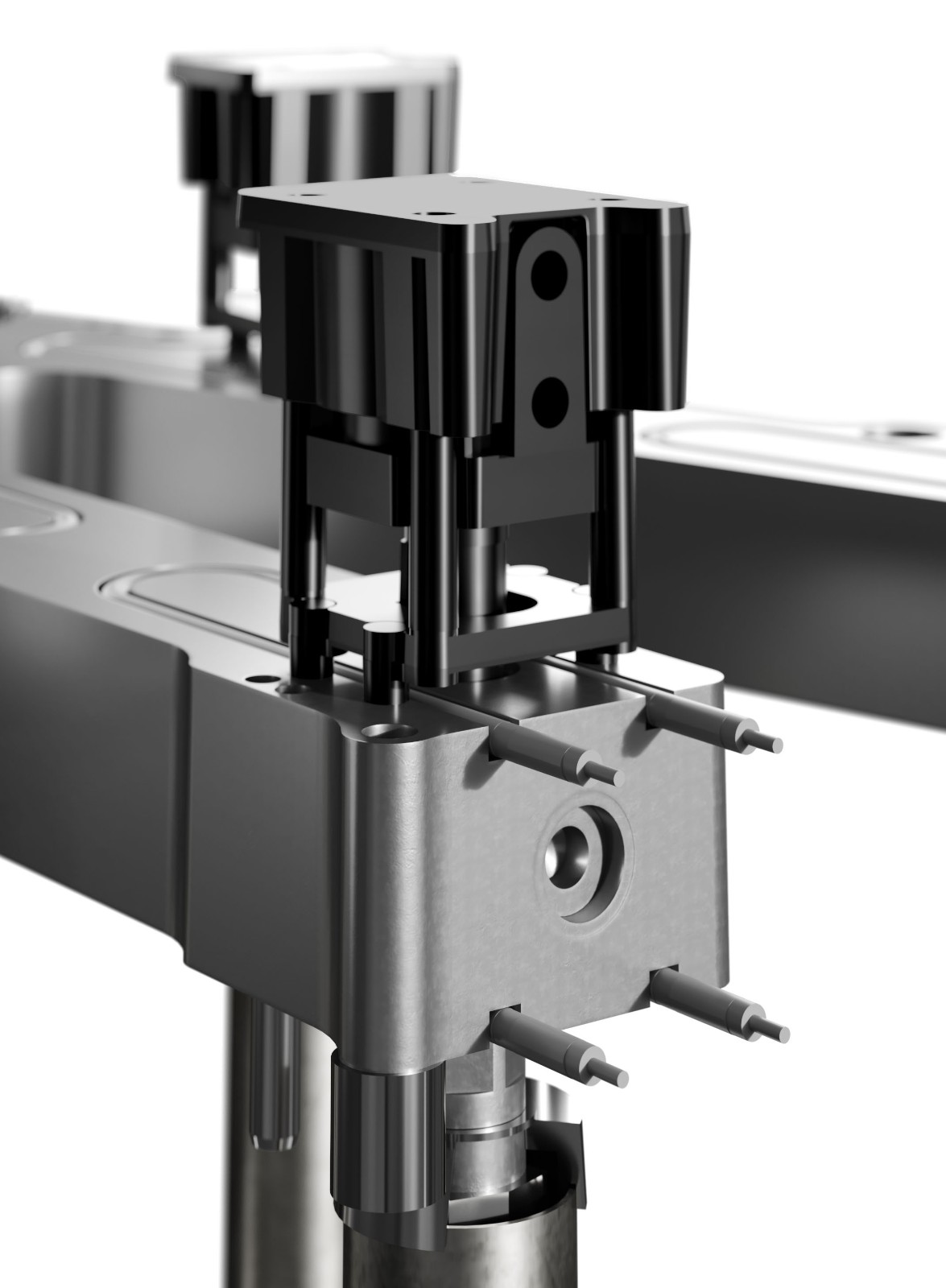

Oerlikon HRSflow’s HRScool Evo is a system where the hydraulic cylinder that positions the pin does not need separate, active water cooling. Depending on the system size and application, this can reduce energy consumption at the drops by up to 10%. In addition, the low number of components reduces the assembly and maintenance time. This innovative technology, which contributes to more sustainability in injection moulding, can replace conventionally cooled designs in a variety of applications across a wide temperature range.

As high-precision actuators, the cylinders of hot runner systems are crucial components for continuously trouble-free process control. In conventional systems, water cooling ensures that the optimum working temperature is maintained. With HRScool Evo, a thermally insulating air gap towards the cavity reduces both the heating of the cylinder and the thermal loss of the manifold. In addition, a cover made of a highly heat-conductive material on the opposite side ensures optimum heat dissipation towards the cold clamping platen. For perfect matching, the height can be adjusted via telescopic supports, enabling outstanding heat transfer and thermal uniformity over the entire hot runner system to maximize part quality. Thanks to the high efficiency, the more complex water-cooled systems can be replaced in many cases without compromise.

By eliminating water cooling and optimizing heat flow, HRScool Evo increases energy efficiency in

hot runner injection moulding.

Says Massimo Rossi, R&D Director at Oerlikon HRSflow: “Thanks to the concept used, HRScool Evo has a wide range of market applications, including the automotive and the packaging industries. Apart from energy efficiency, one of the most important advantages is the elimination of all pipes and connections required for water cooling. Where these are not present, they cannot become clogged or corroded. The ability to remove the actuators while the needles remain in the hot runner system also reduces maintenance. And because the reduction to one thermally insulating and one thermally conductive element enables a compact design, small cut-outs in the clamping plate are sufficient."

Oerlikon offer comprehensive polymer processing plant solutions and high-precision flow control component equipment. The division provides polycondensation and extrusion lines, manmade fibre filament spinning solutions, texturing machines, BCF and staple fibre lines as well as nonwoven production systems. It also develops and produces advanced and innovative hot runner systems and multi-cavity solutions for the injection moulding industry.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login