Two trends are currently in evidence among plastics processing companies: On the one hand, the complexity of systems is increasing through the integration of functions in the mould and/or downstream processing steps in automated production cells. There is rising market demand e. g. for components with pleasant tactile qualities, with joints, or with insulating properties. The wide variety of these additional functions is matched by the options for integrating them. The know-how of experts is in ever greater demand when it comes to finding efficient, value-adding solutions. Thus, the customers want a partner who provides them with comprehensive advice and support on the way to new products and innovations. For this reason, Arburg offers individually matched turnkey systems and provides advice throughout the entire value-added chain.

Mr. Heinz Gaub

Managing Director Technology & Engineering

ARBURG GmbH + Co KG

On the other hand, customers are seeking flexible solutions owing to ever faster product changes, increasing variant diversity and, consequently, ever smaller unit volumes per order, down to one-off parts. These requirements can be met, for example, by combining injection molding, additive manufacturing and "Industry 4.0" technologies to individualise large-volume products in order to create single-unit batches in a cost-effective manner using an automated, digitally networked cyberphysical production system. The internet has reached plastic processing.

Flexibly automated systems as thrust

Arburg is transforming itself into a supplier of flexibly automated production systems for integrated production in the digital factory. With automated Allrounders, the central Selogica control system, the Freeformer for additive manufacturing and IT solutions such as the Arburg host computer system, ALS, we are a true supplier of cyberphysical production systems.

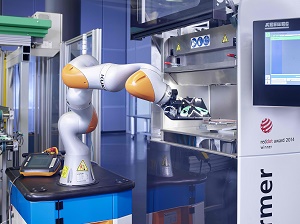

The Freeformer, worldwide launched in spring 2015, is still a highlight. There is a definite demand for the production of functional parts from qualified standard granulates without requiring a mould, whether as one-off parts or in small-volume batches. We have already delivered the first Freeformers to the United States and China. At Fakuma 2015 we presented an automated Freeformer communicating via an Euromap 67 interface with a mobile seven-axis robotic system. The solution is truly unique in the world of additive manufacturing.

Efficient, to specific customer needs configured injection moulding solutions are e. g. our new physical foaming process Profoam, which extends our range of processes for lightweight construction. In the context of micro injection moulding, we offer a complete micro production cell. With regard to sophisticated packaging technology, we offer the “Packaging” version of the Allrounder.

Our extended offering in the area of the large full electric Alldrive machines from 2,500 to 5,000 kN will from now on be available in three performance variants in order to cost-effectively and individually adapt the machines to the specific customer needs. Further novelties will be presented in 2016 at the Arburg Technology Days in March and at the K show in October. Our keyword here is "production efficiency".

Arburg automated additive manufacturing for the first time in 2015.

We see great potential offered by the combination of injection moulding and industrial additive manufacturing using Industry 4.0 technologies. By applying an individual DM code on an injection moulded part the product itself becomes, from this moment on, a data and information carrier and its own website. Using the code, the part-specific web page can be retrieved at any time and from anywhere in the world using a mobile device – even after several years. This plays an important role, for example in the traceability of safety-related parts, such as airbags for the automotive sector and implants for medical technology. This type of traceability is also the basis for just-in-time production. Moreover, different work processes can take place at different times and locations.

Today, Arburg is the only manufacturer in the industry that enables its customers to produce individual plastic parts in lot size 1 or enhance mass-produced parts in order to create added value. It is therefore possible to exploit new market potential for individual components that were previously not economically viable.

Cost savings, increased efficiency, conservation of resources and reduction of CO2 emissions: lightweight design as a "problem solver" is a key topic for the future in numerous industries. The aim is to reduce part weights, while maintaining or improving mechanical properties. Innovative injection moulding processes are required for this purpose. Arburg offers e.g. Profoam for the physical foaming as well as overmoulding of thermoplastic organic sheets, Fibre Direct Compounding (FDC) and particle-foam composite injection moulding (PCIM).

Expansion in Asia

We have successfully expanded our activities in Asia in recent years and will continue to intensify these in the future. At the forefront is China, where business is progressing satisfactorily for us. Arburg is particularly interested in customers who have a long-term vision and who are looking for high-quality, reliable machine technology.

With our subsidiaries in Hongkong, Shenzhen and Shanghai as well as a machine warehouse close to Shanghai we provide the customers of the Chinese injection moulding market with intensive support. Here, the Allrounders produced in Lossburg are temporarily stored and can be locally adapted to the individual customer requirements. We also deliver machines directly from our Shanghai warehouse to Indonesia, Singapore, Thailand or Malaysia, for example.

Mr. Heinz Gaub

Managing Director Technology & Engineering

ARBURG GmbH + Co KG

Tel. +49(0) 7446 33-0

Fax +49(0) 7446 33-3365

E-mail: contact@arburg.com

Website: www.arburg.com

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login