There is no all-purpose workpiece material for machined products. Different product applications require workpiece materials with widely differing performance properties.

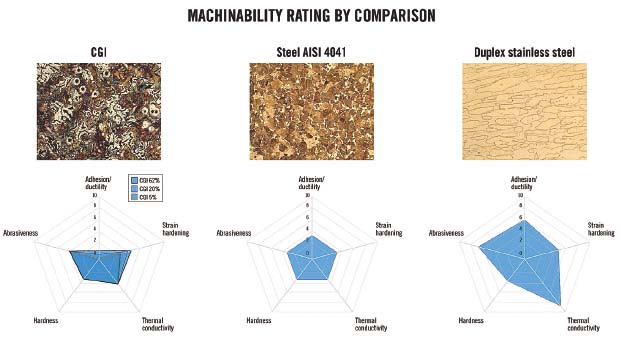

As reflected in their specific performance capabilities, all workpiece materials exhibit different levels of five basic physical properties. Those properties are abrasiveness, hardness, and thermal conductivity as well as tendencies toward adhesion/ductility and strain hardening. The proportions of the individual properties in an individual workpiece material largely determine its machinability. A relatively soft low-alloy steel will exhibit strong tendencies to adhesion that can lead to edge buildup on a tool and diffusion wear, while the poor thermal conductivity of a tough nickel-base alloy can result in extreme cutting temperatures that will cause a tool to deform and fail.

Role of material properties in machining results

In theory, knowledge of a workpiece's specified mix of alloying elements can be used to determine the choice of cutting tools and cutting conditions that will produce predictable wear patterns and good productivity. But the reality is often different. Not infrequently, the cutting tool and machining parameters indicated for a certain workpiece material do not produce entirely satisfactory results.

Variability in workpiece material composition is the reason. As in any manufactured product, a range of tolerance exists for the elements of a workpiece material's makeup.

To confirm this phenomenon, Seco examined a series of pieces of raw stock, all of them nominally the same workpiece material, and measured the five properties before machining. Some of the properties were equal among the pieces of stock, but others showed large differences.

When the basic properties differ between workpieces, the cutting tool will behave differently and productivity may decline. To establish a method to recognise such variations and provide guidance regarding ways to improve tool performance, in the early 2000s Seco joined a project with steel suppliers and other metalworking-related companies aimed at creating a system to measure workpiece properties and use that data to predict machinability independent from applications such as turning, milling and drilling.

Machinability analysis system

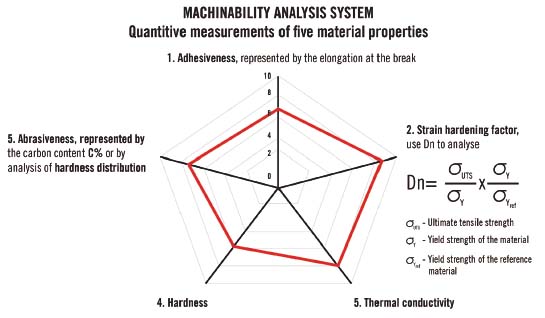

The resulting machinability analysis system is based on quantitative measurements of the five material properties listed earlier. Hardness and thermal conductivity are measured via standard methods. Carbon content or analysis of hardness distribution provides data on abrasiveness. Measuring chip elongation at the chips' breaking point enables quantitative measurement of adhesion tendencies, and a formula relating the material's tensile and yield strength to the yield strength of a reference material produces a measure of strain hardening.

The property data points are charted on a five-pointed grid or pentagram. Low values appear near the centre of the pentagram, and high values towards its borders. The area enclosed by the data points provides a graphic image of the sum of the material's tendencies. Connecting the five single property data point results produces a five-sided polygon within the borders of the pentagram grid.

Separate from picturing a specific workpiece material's blend of properties, the system provides guidelines for each of the five basic properties alone in terms of suggested cutting material, geometry, and cutting conditions. The system also describes typical tool wear patterns.

The goal of machining is to produce parts and make money. A key influence on the machining process is the material properties of the part. Therefore, directly or indirectly the end cost is influenced by the workpiece materials. Better understanding of workpiece material properties leads to fewer problems and greater productivity in the machining process and therefore cost-efficient and profitable manufacturing results.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login