Precise laser cutting in action: Lasers can cut sheet thicknesses up to 25 mm precisely and in complex shapes. (© Surplex).

Laser cutting is a versatile manufacturing process in which a laser precisely and efficiently separates complex shapes from sheets of material. How does a CO2 laser work? And what are its application areas in various industries? Why are lasers ideal for integration into automated production? And can a perfect result be achieved with used machines as well?

Laser cutting is a separation process in which a laser cuts through the material Due to the freedom of movement of a laser, complex shapes can be cut out precisely and efficiently. Depending on the laser parameters (wavelength, average power, pulse energy and duration), practically any material can be cut.

Technical basics of laser cutting

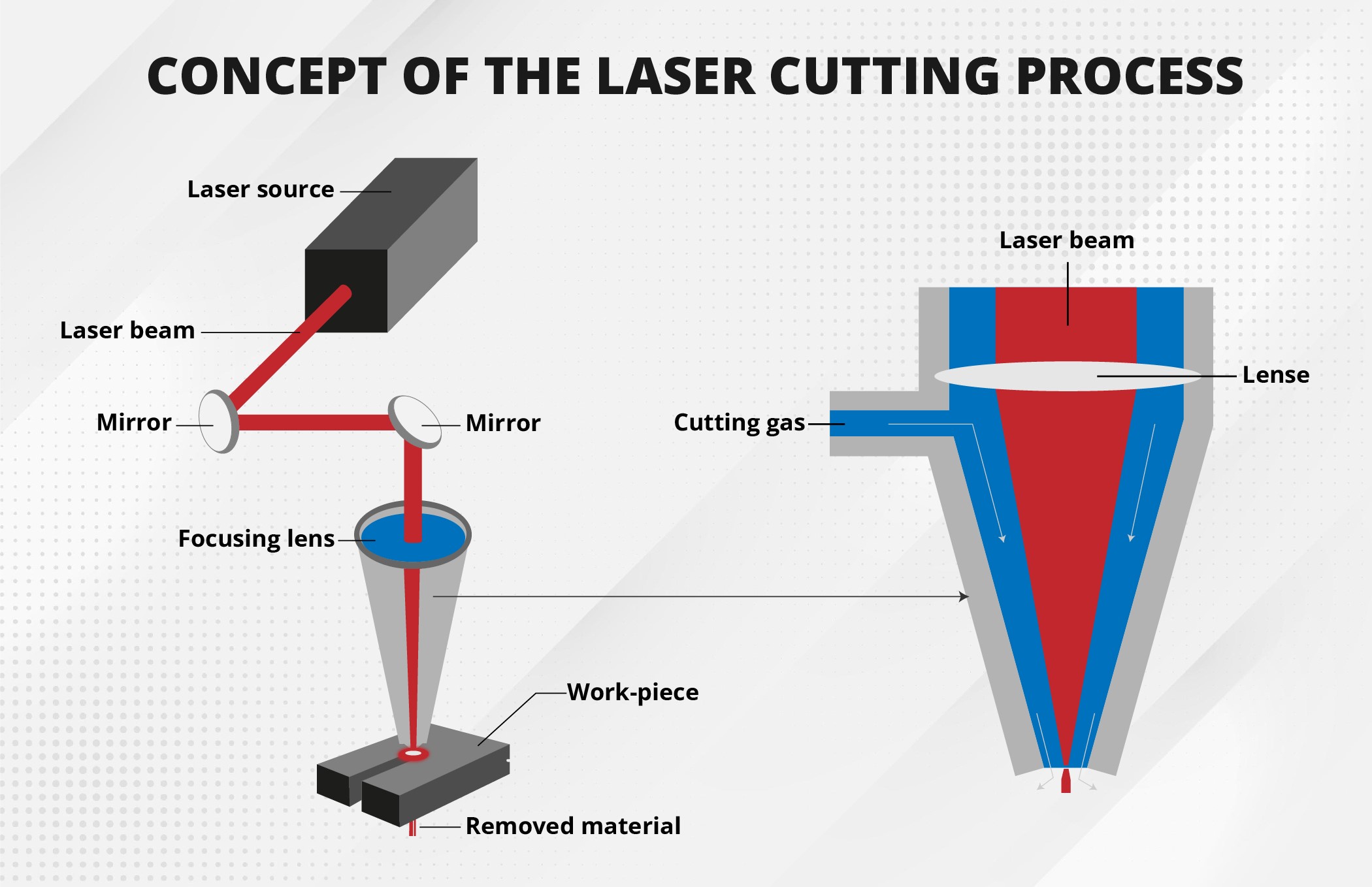

Various laser beam sources are used in the industry, including the proven CO2 laser as well as specialised solid-state lasers such as the Nd:YAG laser, fibre laser or disk laser. The laser beam is directed onto the focusing optics through mirrors (in the case of CO2 lasers) or optical fibres (in the case of solid-state lasers). In this lens, it is bundled and focused to achieve the required power density.

The high energy of the laser beam melts, burns or vaporises the material, resulting in complete cutting. A process gas is used to remove the ablated material from the kerf and protect the optics from fumes and spatter. Laser cutting can achieve positioning accuracies of up to ±0.1 mm and repeatabilities of ±0.05 mm. Depending on the material and application, cutting speeds of up to 250 m/min can be achieved.

Example: ByLaser 6000

The ByLaser 6000 is an industrial CO2 laser with a nominal power of 6 kW, manufactured by the company Bystronic. This type of laser generates its laser beam by exciting CO2 gas with a high electric voltage of several thousand volts. This electrical impulse puts the molecules into an excited state, where they store additional energy. When they return to their original state, they release this energy in the form of light. As the energy release occurs very quickly, a laser beam is produced. In the case of a CO2 laser, such as the ByLaser 6000 the light emitted has a wavelength of 10.6 µm.

The advantages of laser cutting in practice

Particularly in the metal processing industry, laser cutting is in great demand because of its high precision, efficiency, and productivity. By combining it with highly automated CNC technology, a high level of cost-effectiveness is ensured even for small quantities.

The high cutting quality and clean, burr-free edges achieved through laser cutting is a result from the precision and control of the laser beam. The high energy density of the laser beam enables fast and clean cutting through melting or vaporising of the material. As a non-contact process, it reduces the risk of workpiece damage.

A laser cutting system can be ideally integrated into automated production. An essential factor here is the automatic loading and unloading of the machine with sheets This reduces manual labour time, minimises errors and enables continuous production. This automation is particularly beneficial for mass production but can also offer significant advantages in smaller production environments by enabling precise, consistent and fast production.

As laser cutting is a non-contact process, the machine is subjected to less wear and tear, resulting in reduced downtime. Additionally, lasers are low maintenance and have a long lifespan.

This versatile manufacturing process is widely used in various industries, especially in metalworking. It is widely used to cut precise parts for machinery and vehicles, including complex shaped components, veneers, supporting elements, and brackets, as well as for tube processing.

Used laser systems as a wise investment

Probably the biggest disadvantage of laser systems is the high initial investment. However, used machines are significantly cheaper. Since laser devices require minimal maintenance and have a long lifespan, this investment can be worthwhile.

Currently, on the Surplex used machinery market, a high-quality system is available for direct purchase: the BYSTRONIC CNC laser cutting machine BySprint Pro 4020. The integrated ByLaser 6000 has a power of 6 kW and has less than 4,200 operating hours. In addition to the powerful laser cutting unit, the machine is equipped with a Byloader 4020 for automated loading and unloading, as well as an ABUS crane for loads up to 1.25 tons. The Byloader system can handle sheets with a format of 4000 x 2000 mm, and the loading cycle takes only 45 seconds.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login