In addition to Aluminium and Magnesium alloys, special emphasis is once again being placed on plastics in the form of composite structures with metals. The plastic structures in the component offer better torsional stiffness and bending strength, while metal provides the necessary strength. In addition to weight reduction, plastics processing allows for especially complex structures to be produced by means of an injection moulding process.

In contrast to pure metal components, the degree of material utilisation for plastics is moreover nearly 100 percent. Hybrid components also allow additional functionality to be integrated into parts and body components while providing for the division of functional tasks. This enables manufacturers to introduce specialised elements for the purposes of joining and assembly.

Traditionally, in a first production step the metal component will be produced separately. Then it will be inserted in an injection moulding machine and the injection moulding process takes place for producing the plastic part and for joining. This process chain requires numerous process steps in various production facilities.

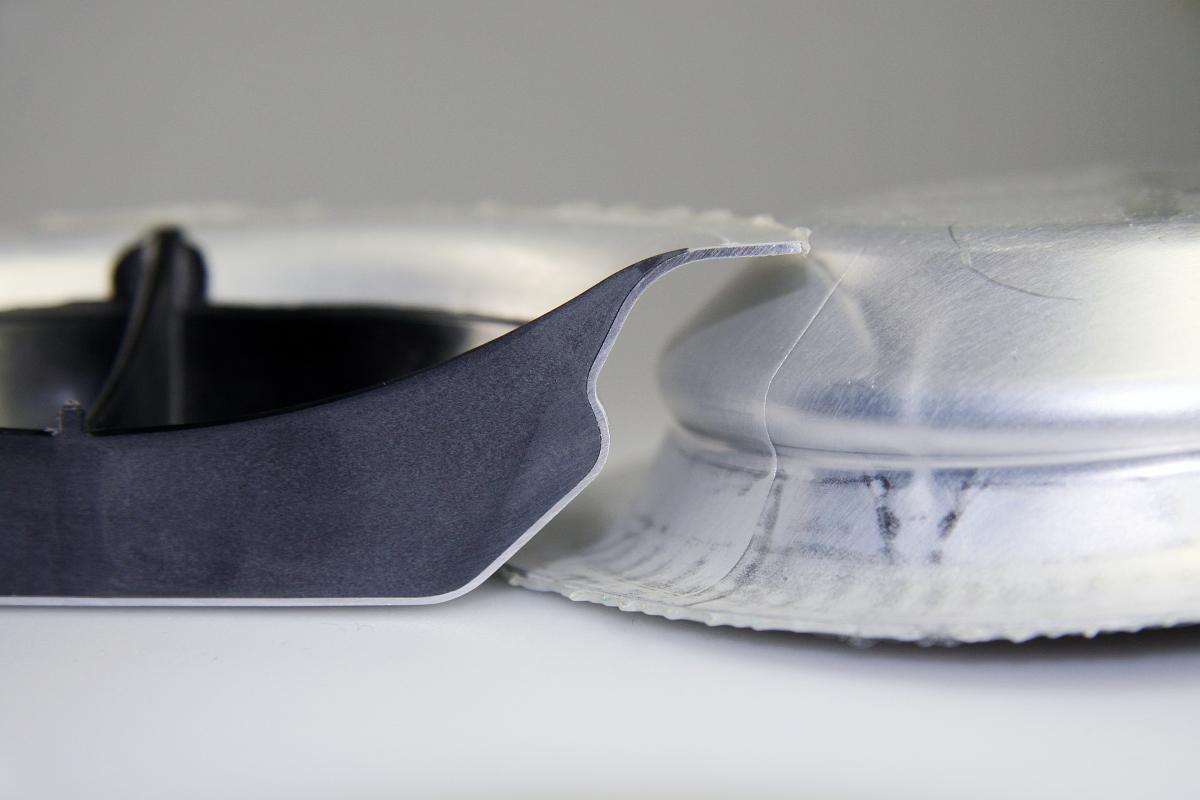

Fraunhofer IWU, working together with Technische Universität Chemnitz, has developed a process combination that allows manufacturers to produce metal-plastic hybrid parts in a single production step. The metal test component is deep-drawn in a first sub-step and the plastic is injected later in the same die. Researchers were able to use the high injection pressure to form secondary design elements in the test component.”

A special challenge was the need to develop a suitable die,” explained André Albert, Group leader at Fraunhofer IWU. In order to achieve the best possible consistency in the injection process, the die must be heated. The die that was developed was fitted into a deep-drawing press and coupled with an injection moulding bolt on unit. The process was stabilised during the course of the tests, and first test components were produced. As a next step, the procedure is expected to be transferred to near serial parts for the automotive industry for application in body components such as engine hoods, B-pillars and cross members.

The process combination not only allows manufacturers to explore further potential for lightweight construction and increase material utilisation: ”The new production process significantly shortens the process chain for producing these hybrid components, leading to considerable savings in both time and cost,” added Albert. This work was performed within the Federal Cluster of Excellence EXC 1075 ”MERGE Technologies for Multifunctional Lightweight Structures” and supported by the German Research Foundation (DFG). Financial support is gratefully acknowledged.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login