The 5-axis machining centres from HELLER’s HF series deliver a significant reduction in idle times, in combination with the powerful dynamics and a horizontal spindle for shortest chip-to-chip times. The machines guarantee high productivity in series production and for universal application when machining medium to large batch sizes.

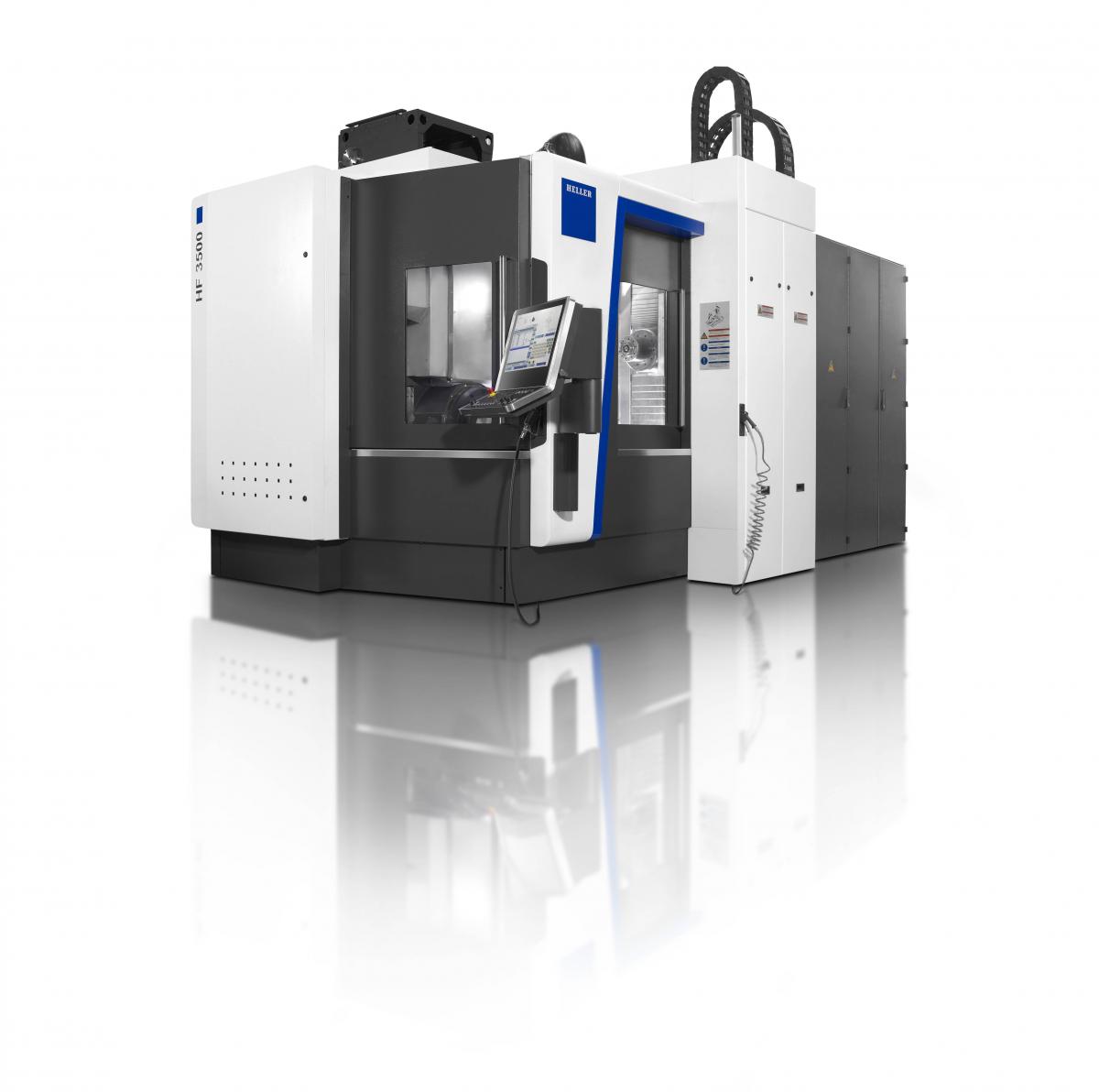

The model HF 3500 for table loading, first presented in 2016 and providing a work envelope of 710x750x710mm and a maximum table load of 550kg, and the new model HF 5500 equipped with pallet changer, providing a work envelope of 900x950x900mm and a maximum pallet load of 750kg, will be taking the spotlight.

Machine concept: robust and highly dynamic

The new HF series comprises 5-axis machining centres proving once again that HELLER genes like productivity, performance, reliability and availability form the foundations of each and every new development from Nürtingen. The HF series combines proven qualities with innovative features. This is also true for the kinematics with three linear axes in X, Y and Z, equipped with absolute measuring systems and two direct driven dynamic rotary axes in A and B integrated into a swivel rotary table. Dynamic because the high speed of the A and B rotary axes is achieved through minimised mass moment of inertia and the use of direct drives. Optionally, the powerful dynamics can be increased further with the “Speed-Dynamics Package”. According to HELLER, it provides 10 % shorter chip-to-chip times. For an additional reduction in idle times, the HF series provides a high-speed NC tool changer with lift-and-swivel principle.

Contrary to comparable machines on the market, HELLER has equipped the new series with a counter bearing as a unique selling point. The use of the counter bearing in combination with a YRT bearing results in high rigidity also in case of high loads.

High flexibility was another priority for HELLER in the development of the machine. Therefore the machining centre is either available in table design or equipped with pallet changer.

Spindle units: top quality made by HELLER

Combined with the 5th axis provided by the workpiece for dynamic 5-sided and simultaneous 5-axis machining, HELLER's typical horizontal spindle, ensuring quick tool changes and short idle times, offers substantial advantages as far as productivity is concerned. The HF provides a wide choice of spindles to suit different applications. Whilst the standard version is equipped with the powerful SC63 SpeedCutting motor spindle with HSK-A63 (18,000rpm, 100Nm), making it ideal for the machining of light metals, the optional PC63 PowerCutting spindle unit (12,000rpm, 201Nm) provides the necessary torque for high-performance cutting of cast iron and steel. As further options HELLER offers motor spindles with HSK-A100. The SC 100 spindle unit (12,000rpm, 201Nm) provides increased stability of tools and high speeds for universal application, whereas the PC 100 spindle unit (10,000rpm, 354Nm) offers high torque for use with large and heavy tools.

Work area: adequately dimensioned and ergonomically designed

Moreover, the HF series provides large workpiece interference contours. Contrary to conventional 5-axis machining centres, HELLER's concept is not only based on single-part clamping, but provides the possibility of multiple clamping or the clamping of very large components (e.g. transmission cases using 'window-type' fixtures). To provide sufficient space in the work area, the workpiece interference contour of model HF 5500 was increased by 800mm in height and 900mm in diameter compared to model HF 3500, equalling a difference of 27 percent. What is interesting is that despite the large interference contour there are hardly any limitations as far as the degrees of freedom are concerned. The machine enables swivel movements of the rotary table through 150° (30° to -120°) and with certain restrictions even through 225°. The HELLER HF machining centres leave nothing to be desired when it comes to the disposal of short- or long-chipping materials. This is guaranteed through free chip fall during horizontal machining, steep side walls and stainless steel slat coverings as well as the centrally arranged open chip conveyor.

Operation: convenient and practice-oriented

With the HF series, HELLER is presenting its new HELLER Operation Interface, the new operating panel with 24" screen technology and touch controls, quick access technology in the control and XTENDS optional expansion applications to support the user. The optional work area camera, for example, optimally supports setting and monitoring functions during the CNC process.

Automation: efficient and future-proof

For decades, HELLER has been synonymous with efficient production processes and high machining quality. This also applies to the well-conceived connection to all current automation systems. Target groups will be particularly interested in flexible integration into existing production systems. The new machine series is also flexible and customer-oriented in terms of tooling. The new machining centres enable continued use of existing tools from other HELLER machines and the use of manual clamping fixtures. Adaptation of hydraulically operated clamping fixtures is also possible.

Nike Air Max Plus TN

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login