The advantages of automating the production system have always been stressed in today’s highly competitive environment. Many companies in the plastics industry have taken the route towards automation, utilising a growing number of products that would aid them in automating their production systems. New technologies and devices can now be installed and integrated into the production system to aid automation and improve productivity.

Dynamic functionality

With the CP32xx Panel PC series from Beckhoff Automation, industrial multi-touch display technology can be used in an all-in-one, high-performance automation device for HMI and control applications. These powerful devices for mounting arm installation feature all-around IP 65 protection and integrate best-in-class multi-touch Control Panel technology with a high-performance Industrial PC (IPC) – all in one rugged, yet compact housing.

The area at the rear of the CP32xx Panel PC, which is required for swiveling and tilting the connected mounting arm, is also efficiently used to accommodate the added IPC components while saving space. The components in this solution are thermally decoupled from each other; to save space, the computer is actually built around the integrated mounting arm in a u-shaped housing with cooling fins for passive cooling.

Another advantage is the excellent heat dissipation characteristics despite the compact design, achieved using internal fans; this ensures even temperature distribution to all walls of the housing. This results in an impressive operating temperature range from 0 to 45 °C. Moreover, all components and connectors are easily accessible, which is convenient when using removable storage media such as a CFast card or SSD. The connecting cables are laid through the support arm into the connection compartment for up to six IP 65-rated connectors. In the basic configuration, two of the connection points are configured with an Ethernet interface or power supply; the remainder are optionally available for a further Ethernet, USB or serial interface, or for a Mini-PCI fieldbus interface. The cylindrical connector hood in the center of the device is easy to remove. This enables convenient access to the connection compartment and also facilitates simple cleaning of the cooling fins if necessary.

For maximum computing power beyond the standard dual-core 1.6 GHz Intel® Celeron® CPU, the CP32xx Panel PC series also offers the option to use Intel® Core™ i series processors of the second, third and fourth generations. Two cores can be leveraged with Intel® Core™ i3 and i5 processors and four cores with the i7 processor. Offering maximum selection, CP32xx Panel PC displays are available in 12 to 24-inch sizes, in both 4:3 and widescreen formats, as well as with landscape and portrait orientation options. The aluminum housing design ensures the Panel PCs are exceptionally robust and ideally suited for industrial applications. A narrow, circumferential metal impact protector reliably protects the touchscreen surface, including the display against mechanical destruction. The all-glass surface is chemically hardened, has an anti-reflection coating, and offers maximum resistance to environmental influences. The multi-touch panels with projective capacitive touchscreen (PCT) technology feature a high touch-point density, enabling accurate, safe, and jerk-free operation – even in minute steps. The panels can also be operated with thin latex work gloves. Five-finger touch and operator interface solutions requiring 2-hand operation are equally possible.

CP32xx Panel PC series from Beckhoff Automation

Protecting automation systems

Siemens AG has been active in more than 200 countries, focusing on the areas of electrification, automation and digitalisation. The company has been providing software solutions that aid automation and its latest addition, Scalance S615, enhances its security module product line.

Scalance S615 is a cost-effective entry-level device from the Scalance S range which protects industrial networks and automation systems against unauthorised access. The Scalance S615 security module has five Ethernet ports that offer protection for various network topologies via firewall or virtual private network VPN (IPsec and OpenVPN) and enable flexible implementation of security concepts. Users can configure up to five variable security zones with individual firewall rules. With the autoconfiguration interface, the device can be easily integrated and parameterised with the Sinema Remote Connect management platform. The management platform lets users conveniently manage network connections and access widely distributed plants and machinery.

Scalance S615 from Siemens

The Scalance S615 security module has various configuration, management and diagnostics options via web-based management (WBM), command line Interface (CLI) and simple network management protocol (SNMP). As a dynamic host configuration protocol (DHCP) server and client, the device can be used in any virtual local area network (VLAN) security zone. The device has a key-operated switch function on its digital input for establishing a controlled tunnel connection.

The security modules in the Siemens Scalance S family connect seamlessly to the security structures of the office and IT worlds and are specially designed to meet the demands of automation systems with features such as a rugged design for industrial environments, easy installation, minimal downtime in the event of faults due to a redundant power supply, and rapid device replacement via C-plug. Depending on the level of security required, the firewall and VPN security features can be combined.

Cost reduction and improved productivity

Software development is the most expensive element of the vast majority of automation projects. By providing a unified development environment for the complete scope of automation projects, ABB is helping application experts, software and hardware engineers to focus their time and effort purely on developing the application, and not waste time on the myriad of interfacing issues that can arise when building solutions using many different types of automation devices.

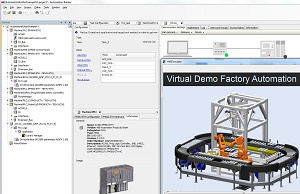

The speed and efficiency of industrial control and machinery automation projects is further enhanced significantly with a major release of ABB's integrated development toolsuite. Automation Builder 1.1 provides an integrated development environment for solutions using the spectrum of automation components - including PLCs and safety PLCs, motion controllers, drives, robots and HMIs - substantially reducing software complexity and cutting time to market and cost of ownership.

ABB's Automation Builder integrated development environment for automation components

Among many new features, the latest release of ABB's software extends the data exchange capabilities with electrical planning and engineering software, with a new bi-directional interface to the widely-used EPLAN Electric P8. Electrical automation and PLC design data may be imported, modified and transferred back to the electrical CAD environment - eliminating any need to manually enter data and thereby ensuring synchronisation of signal identification between the two software environments. The release now includes a comparison function that allows engineers to see what might have changed since they last looked at a project, and the ability to use profiles of previous development tool versions for compatibility.

Support for new hardware includes the ability to program the latest member of the well-known AC500 PLC family - the PM595 CPU - programming ACS880 IEC61131-3 programmable drives and the DCT 880 thyristor power controller, and developing motion control systems with ABB's new MotiFlex e180 servo drives or the ACS580 general-purpose drive.

With Automation Builder 1.1, users may also automatically update the suite of software tools to the latest versions using a 'one click' mechanism, and a single license covers all of the software packages included. ABB has also introduced many usability improvements to further enhance the user’s productivity. These include simplified drop-down menus, drag-and-drop features on the object tree, an improved device repository with search and filter functions, a powerful list editor for AC500 I/O mapping, and a re-worked help system - to name a few.

ABB estimates that the Automation Builder environment can reduce development engineering effort by around 30% for medium complexity projects, and deliver even higher savings on large-scale projects! This is particularly the case for projects involving many different types of automation components.

Automation Builder provides powerful PLC development resources in the form of the standards-compliant IEC 61131-3 development environment, and ABB's Panel Builder tool for creating HMIs. The software suite also includes tools for configuring and programming the latest generation of ABB’s safety PLCs - the AC500-S family - the RobotStudio tool for simulating and programming ABB robot applications, and the Mint WorkBench tool with its pre-built and tested libraries for programming ABB’s servo drives.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login