Optical measurement is gaining support in the NDT (non-destructive testing) applications. In its quest for efficiency, the oil & gas industry shows increasing interest for fast and reliable solutions in pipeline integrity assessment. Addressing the needs of the industry, Creaform has made major improvements that will make the assessment take a whole new turn.

All pipeline operators are aware of the potential impact of a catastrophic failure that complex or combined damage can lead to. Being able to measure accurately the damage contribution to pipeline integrity will directly increase the level of confidence in their pipeline integrity management program, resulting in a lower maintenance cost and a reduced risk of costly failure.

New functionalities

Being able to separate material loss depth from mechanical damage deformation is no longer a dream with the new Pipecheck version. Combined with the HandySCAN 3D handheld laser scanner, the new Pipecheck version can now be used in complex situations that could hardly be addressed before. The Pipecheck software offers unique and sophisticated tools able to extract corrosion depth within a mechanical damage. Featuring numerous key functionalities that allow a better understanding of dents and localised surface deformations, this new version of Pipecheck will generate instant results, a key factor in the reduction of maintenance costs.

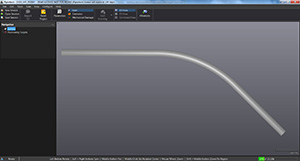

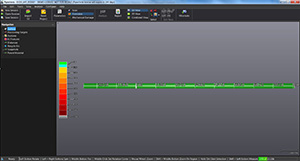

Another major improvement is the built-in straightening operation for assessment on field bends that is also available. In many cases, small mechanical damage is found on field bends, mainly introduced by human manipulation when building the pipeline or by soil movement, ice, etc.

Traditional methods for depth measurement like pit gauge can’t be used accurately since the pipe curvature often introduces depths value that do not represent the material loss or pipe geometry deformations. To solve this issue and to improve efficiency and confidence in results, Pipecheck features a built-in straightening tool. The tool uses powerful algorithms that extracts pipe’s centre-line and straightens the full segment. The material loss or mechanical damage can then be assessed with the virtual Pipecheck’s pit-gauge tool to report depths reading free of any pipe curvature.

Cost saving and reliable solution

Although traditional methods may seem cheaper in comparison with an integrity assessment software like Pipecheck, the cost saving of the tool is quickly overtaken by an important number of labour hours for the measurement and by a time consuming analysis.

Unlike the direct competition, Pipecheck has unprecedented accuracy, reduced chances of human errors and a better record archiving method. Therefore, its sophisticated analysis allows a reliable damage assessment, resulting in lower maintenance costs and reduced risks of major failures.

Corrosion in mechanical damages

Being able to separate material loss depth from a mechanical damage deformation is no longer a dream. Pipecheck software is the one and only solution on the market to offer unique and sophisticated tools able to extract corrosion depth inside a mechanical damage. All pipeline operators are aware of the potential impact of a catastrophic failure that complex or combined damages can lead to. Being able to measure accurately both damages contribution to pipeline integrity will directly increase the level of confidence in their pipeline integrity management program. This confidence will result in a lower maintenance cost and in a reduced risk of costly failure.

Straightening operation

Experience has shown that various riser tubing are areas that may develop material loss, resulting into corrosion damage after many years of operation. In many cases, small mechanical damages were found on field bends, mainly introduced by human manipulation when building the pipeline. Offshore pipeline may be affected by damage caused by soil movement, ice, etc. Traditional methods for depth measurement (pit gauge) can’t be used accurately since the pipe curvature often introduces depth values that do not represent the material loss or pipe geometry deformations. To solve this issue and to improve efficiency and confidence in results, Pipecheck features a built-in straightening tool. The tool uses powerful algorithms that extracts pipe’s center-line and straightens the full segment. The material loss or mechanical damage can then be assessed with the virtual Pipecheck’s pit-gauge tool to report depths reading free of any pipe curvature.

TO

TO

The ILI Correlation tool is used to correlate in-line inspection data with the Pipecheck 3D scanning inspection data. The user interface has been optimised to compare depth, length, width and burst pressure.In order to properly assess the performance of the ILI tool, pipeline operators need to carry out statistically significant population analyses with the help of a device that offers a better accuracy than magnetic-flux leakage (MFL) technology. The HandySCAN 3D scanners quickly capture metal loss and damage areas and they help building a larger and acceptable population for statistical analysis. Operators can assess ILI performances by comparing pig data against Pipecheck data to help them determine with more precision the sites that actually need to be dug.

Nike Air Max

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login