Plastic is a valuable resource. Far too valuable to dispose of after a single use. Therefore, it is important to manage it in cycles. With ENGEL plastics recycling technologies, a new energy-saving plastics cycle can be closed. Direct processing of regrind on the injection moulding machine saves costs, energy and CO2. “Design for recycling” is also made possible. At the end of their service life, our customers' products are returned to the cycle.

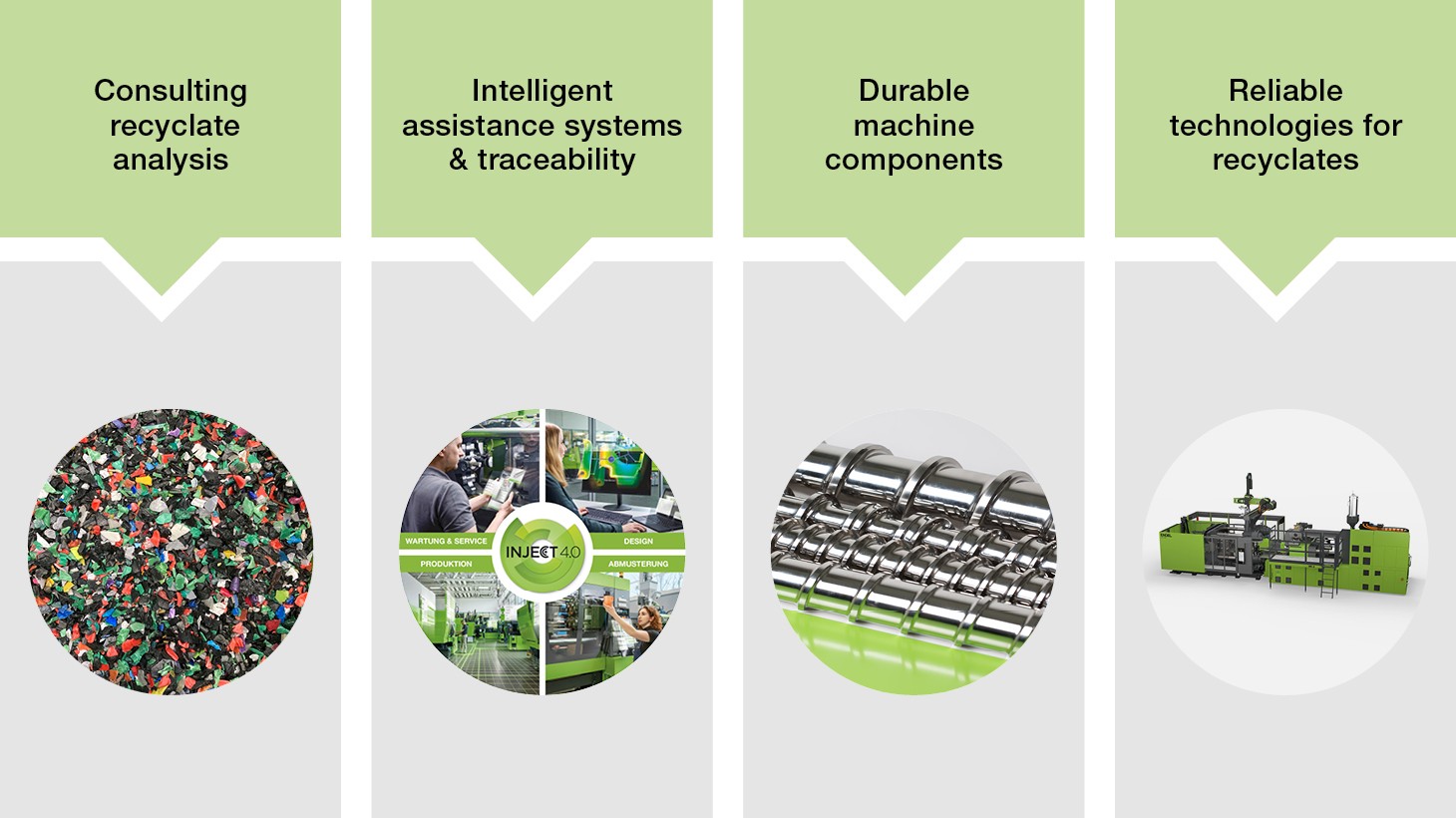

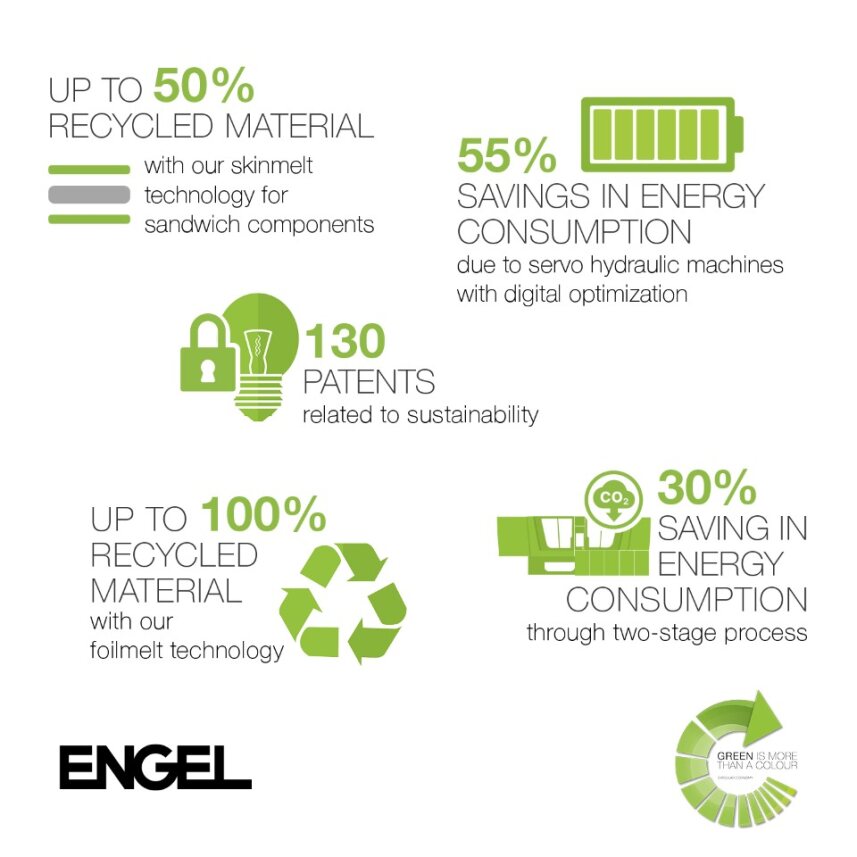

ENGEL has been active in the area of the Circular Economy for years. Our services range from free material analyses to digital products and innovative plastic recycling processes which allows for 30% savings in CO2 footprint, energy and costs in plastics recycling.

Procedures such as PET/rPET processing, used in the packaging industry, or sandwich injection moulding and foil back-moulding, popular in the Automotive and Electronics industry can increase the use of recycled material helping manufacturers produce more sustainably.

In addition to these technologies, ENGEL has also developed a two-stage injection moulding process, which allows for direct processing of regrind material with degassing and filtration of the melt, cutting out the regranulation process and thereby saving energy and reducing the CO2 footprint related to that part of the value chain. The two-stage process is perfect for various industries and applications such as bumpers, engine covers, logistics pallets and buckets.

In Southeast Asia ENGEL has a showroom and training centre located in Bangkok, Thailand - where interested parties can come to see ENGEL machines and technologies live or schedule a training on plastics and injection moulding technologies.

Further information on visiting the showroom contact info.th@engelglobal.com; information on training courses in Southeast Asia contact training.th@engelglobal.com

For more information on ENGEL recycling technologies visit www.engelglobal.com or contact your local sales.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login