THE ROBOTICS market in the food industry is steadily growing, industry experts say. With increased urban living and population growth, the demand for packaged foods has increased globally. Consumers are also becoming more health conscious and demanding fresher products that require shorter delivery times and better packaging. At the same time, increasing concern for food safety is also translating into the requirement for food and beverage products that have been untouched by human hands during processing.

The US Food Safety Modernization Act of 2011, which focuses on preventing food contamination, has had a noticeable impact on the global robotics industry. In a manual operation, there is a higher chance of data errors in relation to tracking tainted products. Companies that utilize robotics systems in their facilities are better equipped at tracing potentially contaminated perishable items and preventing further contamination.

“Food safety is not the only concern for the industry. Consumers are spending an estimated $1.8 trillion per year on food, and are demanding faster deliveries and increasing varieties, pressuring manufacturers to strive for new goals,” says Suzanne Sweerman, executive director of the Netherlands Foreign Investment Agency, a division of the Dutch Ministry of Economic Affairs that is based in Singapore and offers complimentary advice and consultation to foreign companies planning to establish, expand or diversify their business operations in the Netherlands and European markets.

Suzanne Sweerman, executive director of the Netherlands Foreign Investment Agency

Palletizing, packaging, and packing make up the bulk of applications robots undertake in the food sector. But, what automation companies are seeing now is the movement of robots into upstream processing. To accommodate a variety of demands and raise the standard of food safety and traceability, plant, distribution, and supply chain managers are embracing automation and robotic systems at an unprecedented rate.

Shifting industry trends

For decades, advanced industrial robotics were pioneered and deployed by the automotive industry. In 2005, manufacturers of automotive component companies, according to a PWC report, made 69% of all industrial robot orders in the USA. By 2014, that figure had eroded to 56%, offset by increasing shares by other industries including food and beverage and consumer goods. In the UK, robot sales outside of the automotive industries achieved a new record in 2014, with the food and beverage industry being the largest within this group. Robot sales in 2013 for this sector registered a growth of 28%, compared to 2012.

Industrial robots form an essential part of the manufacturing backbone of Europe through cost-effective production, notably in the automotive sector but this is quickly expanding to other sectors from agro-food to electronics. Europe is one of the world leading regions in industrial robotics with a share of more than 25% of supply and use, and the sector is expected to see an average growth of 6% annually to reach more than $32 billion by 2016, the International Federation of Robotics (IFR) reports. The European food industry is booming with an annual turnover in excess of 1,000 billion euros. As a strong exporter and largest manufacturing sector in the region, the market is becoming more competitive with increasing labor costs and market competition. Manufacturers are moving towards process automation to increase productivity, improve safety and quality, and reduce process errors.

“In terms of manufacturing, the European food industry continues to evolve, with many companies utilizing available technologies developed for the non-food segment and adapting these to the food sector,” said Ms Sweerman.

Asia not far behind

While Asia may lead the industrial robotics market, this is concentrated on the automotive sector with countries like Japan and Korea at the helm. On the other hand, the launch of cost effective, low cost and energy efficient robots in the USA and Europe are stimulating the robotic demand from diverse industries, beyond their current focus point. Asian countries are fast catching on, with international manufacturers gradually shifting their production bases to the region.

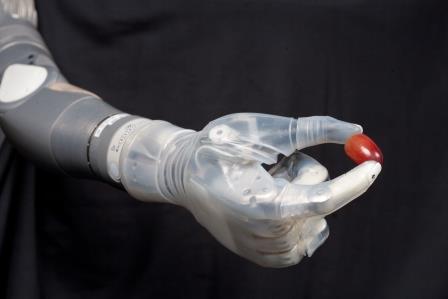

Ever so gently, a well-designed robotic arm will not bruise a product

Riding the technology wave

The food processing industry combines an extensive diversity of products, packaging types and handling variations than almost any other industrial sector. There is a wide range of potential applications for robotics in food processing from the meat sector, where robots are used for cutting to sorting, and packaging applications for fruit and vegetables, and cheese production where they stir and transfer cheese molds, and turn, cut, portion, package and palletize the cheeses.

As the world’s second largest exporter of agricultural products, after the US, the Netherlands is one of the world’s three leading producers of fruit and vegetables. It supplies a quarter of the vegetables that are exported from Europe. Efficiency is what makes this country an agricultural powerhouse but it also creates a landscape for innovation. Focus on robotic technology is but a natural step towards achieving higher productivity and creating new markets and products.

Robotics is a fast developing market increasingly driven by the development of novel and improved products in areas as diverse as manufacturing. For the Dutch, it is clear that the importance of robotics lies in its wide-ranging impact on Europe’s capacity to maintain and expand a competitive manufacturing sector, particularly the food sector. That is why the country is riding the technology wave to keep up with consumer demands for fast, fresh and a safe food supply.

Several innovative Dutch technologies have already hit the domestic market and are fast gaining global attention.

Icing on the cake

When a Dutch bakery De Bakker decided to improve decorating process of its popular petit fours, the Dutch bakery had no idea that robots could increase its capacity by as much as 1,000%. The bakery is known for its specialty high-quality petit fours comprising layers of cake, jam, butter cream and marzipan. Production of such treats is time consuming. For instance, intermediate freezing is required. As layers are added, the products need to be taken offline and placed in a freezer. The final product is also frozen and results are relatively expensive, up-market cakes that are sold in select shops and consumed in restaurants and hotels. Many of these retail outlets are also demanding customization with distinctive decorative icing and their logos.

De Bakker uses robots to add the designs on its special petit fours, which are made of layers of cake, jam, butter cream and marzipan. Semi-automating production has boosted the company’s yield 1,000%

De Bakker turned to automation specialist, Hacos which proposed using robots and specialized software to perform the job. The result is a staggering production increase from 6,000 to 30,000 cakes per day. Using ABB robot solutions, the bakery’s cakes are now made using a semi-automated process. These are frozen, sliced into three 1-centimeter layers and placed on the cutting machine to be cut to the required size. Cream, jam and butter cream are added, followed by a new layer of cake, more butter cream, marzipan. Then the pallets go into the freezer. At this point, the fully automated part of the process begins – the rectangular product is cut into individual squares that are separated, enrobed, cooked and finally decorated. The cycle time is 8-10 minutes. The robots are used to add distinctive designs on top of the cakes. De Bakker has close to 20 designs, and the graphic pad and Windows software developed by Hacos enable new designs to be created in a matter of minutes.

Ripe for gripping

Lacquey BV began developing a ‘careful robotic hand’ at the TU Delft Robotics Institute in 2010. Using the under-actuation technology that TU Delft has been researching for years, the robotic hand allows the product (even the oddly shaped ones) to determine the position of the fingers without the use of a sensor. The torque of just one direct motor (DC) is equally distributed over the contact surfaces to ensure a delicate grip without damaging the object. A universal control box is supplied with each gripper to regulate the grip force and/or closing speed. Only high quality (food grade) parts and materials are used in Lacquey’s grippers allowing an operational lifetime of at least 5 million cycles. The contact surfaces are treated with a special food grade coating for easy cleaning.

“Gripping carefully is actually a matter of a good mechanical design of the robotic hand, in which the power of a motor is evenly distributed over the phalanges,” explained robotics expert Martijn Wisse of the Delft faculty, 3ME. The robotic grippers are not only careful but they are also able to handle different kinds of products.

A gentle grip depends on a good mechanical design where the power of the motor is evenly distributed over the phalanges says robotics expert Martijn Wisse of the Delft faculty, 3ME

The robotic arm is capable of picking up and sorting fruit and vegetables without damaging or bruising them – a holy grail in this sector. In March 2015, Food Technology Noord-Oost Nederland BV (FTNON) purchased a majority share in Lacquey. FTNON is global producer of machines for the food industry with international offices in the USA and China. Through this investment, the manufacturer offers the Lacquey technology to existing customers, and aims to take the Delft startup to the international market, while providing funding for the company to improve its technology to cater to the confectionery and baked goods market.

State-of-the art milking system

Dutch maker of farming technologies, Lely, installed their 12,500th cow-milking robot in 2012. With that, hundreds of thousands of cows all over the world are producing tens of millions of liters of milk per day at the pumps of robots rather than the hands of farmers. If you’re not familiar with Lely’s Astronaut A4 robotic milking system, it is essentially a boxed area where the cows are milked at their leisure. At the milking station, 3D cameras target their teats with a ‘teat detection system’ and milk the cow. After milking, a series of brushes cleans the cow and a swinging feeding trough “encourages” the cow to leave and make way for the next in line.

A high-tech milking system is more than milking the cow. It automates milk testing and sends the data to the farmer’s smartphone. Data include fat, protein and lactose levels as well as signs of bacterial breast infection. Automated brushes clean the cow and trigger the hormone oxytocin whicih stimulates milk production

The appeal of the Astronaut A4 is not only that it automates the milking process. It also automates milk testing right at the milking station and pushes the data to the farmer’s smartphone. Detecting a bacterial breast infection called mastitis, and measuring fat, protein and lactose levels allow the farmers to monitor the quality of their milk. An automated brush system not only cleans the cows and cuts down on milk contamination, but through tactile stimulation, will trigger the hormone oxytocin that stimulates milk production. Milking speed and dead milking times are also monitored so the farmer can make adjustments if he needs to increase productivity. The end result is reduced labor costs and increased productivity. According to Lely, the Astronaut system produces 10-15% more milk than conventional farmers who typically milk twice a day.

“Today’s emerging manufacturing technologies are extremely adaptable, both in terms of function and the way they integrate into the overall production process. In the long run, as technology becomes cheaper, companies will have to embrace robotics as an innovation solution if they are to remain competitive in the global marketplace,” said Ms Sweerman.

For more information on robotics and innovative food technology or investment opportunities in the Netherlands, contact the Netherlands Foreign Investment Agency: Ms Suzanne Sweerman, Executive Director, South East Asia, at Tel: +65 6739 1135, Email: sweerman@nfia-singapore.com / Ms Adeline Tan, Senior Project Manager at Tel: +65 6739 1137, Email: tan@nfia-singapore.com or visit www.nfia-singapore.com

Nike Zoom Kobe Icon

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login