By: Kathryn Gerardino-Elagio

We hear a lot of things about smart manufacturing and how it can improve visibility into costs, efficiency, and quality across factories. In a one-on-one interview with International Metalworking News for Asia, Chris Lee, Regional Vice President of Software Business for the Asia Pacific at Rockwell Automation, explored why Rockwell Automation is a frontrunner when it comes to Connected Enterprise Production System.

During the interview, Chris identified three major trends driving today’s competitive industrial manufacturing environment in Asia Pacific. First is the rise of the middle class in emerging economies. This means we must compete in their markets, and with them for our business. Second is the need for more people who can deal with technology-- the skills gap. In the Singapore alone, there are hundreds of good manufacturing jobs going unfilled for lack of people with the right skills and talent for today’s environment. Chris believed that this also holds true for the rest of Asia Pacific. “People are retiring and struggling to replace themselves,” he said. Third is globalisation. He added, “We all compete against the very best in the world, all the time.”

Bringing Connected Enterprise to Life

To thrive in this changing landscape, manufacturers need a higher grade of flexibility and the ability to react to change at speed. Conventional, more siloed manufacturing approaches are unable to deliver the interconnected, insights-based approach necessary. Instead, it requires a holistic system engineering approach to make data-driven decisions across production. This approach encompasses a range of areas including R&D, integration with business systems, product development and plant floor operations.

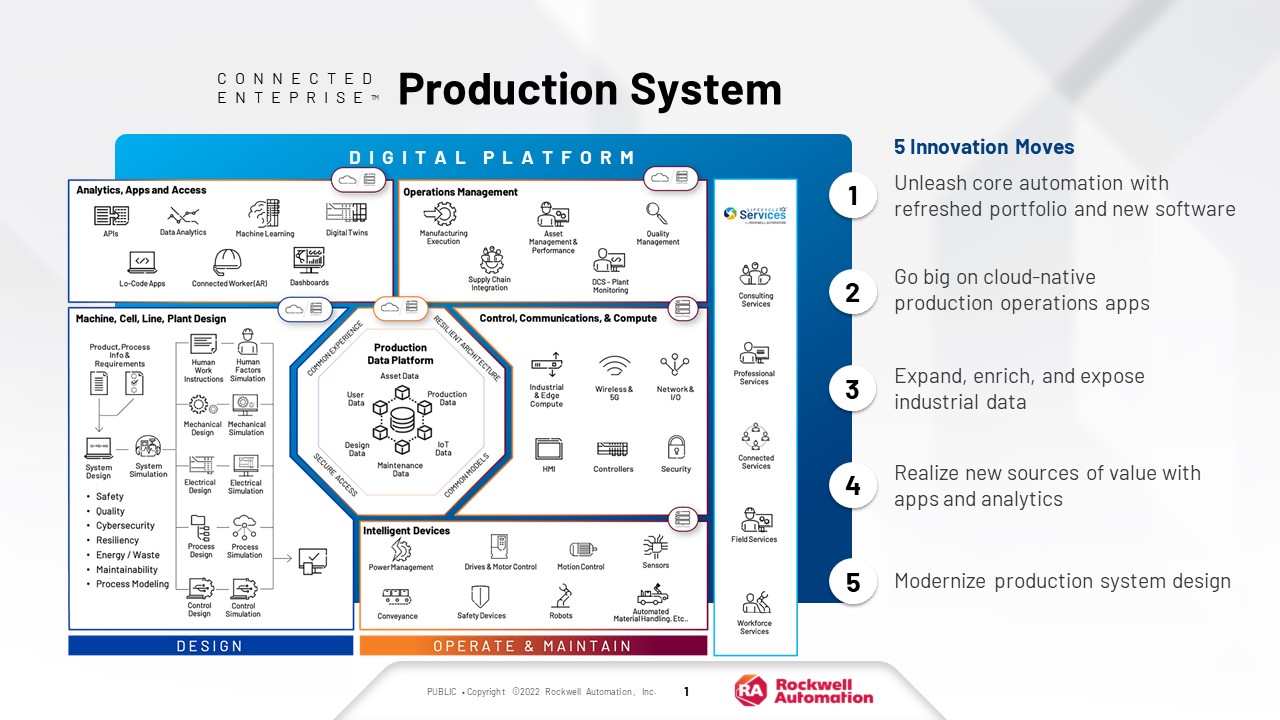

Chris explained that Rockwell has a strategy to implement the needed connectivity and it is called, “Connected Enterprise®.” According to him, this concept converges plant-level and enterprise networks, and securely connects people, processes, and technologies.

But the challenge of implementing a Connected Enterprise successfully is to collect and analyse data. The holy grail of smart manufacturing is therefore a feedback loop that enables companies to improve processes and avoid problems in order to allow them to achieve greater efficiency. How can manufacturers design automation systems that blend software and hardware to deliver a connected and collaborative environment?

One important enabler is the convergence of IT and operations technology (OT), taking the best from commercial technology and practices. Chris mentioned that Rockwell offers this in service-level agreements where its value-add is expertise in the applications. IT provides the know-how to sift data, and we know where to look.

Data is born on plant-level devices and brought up through controls into information systems to help operations make better decisions and be more productive. Chris revealed that Rockwell can do this on one network. The company applies these concepts in its own facilities. They are not as automation-intensive as many of its customers’ sites but the benefits have been amazing and they come from the basics. By understanding work practices and potential savings, Rockwell Automation plants have reduced work in process (WIP), error-proofed procedures and reduced rework. Results like ‘reduced time to market’ are tangible and drive sales for them. Each plant starts from a unique point, with its own opportunities to add value.

In Phase 2, the company is adding data streams from its supply chains, using the cloud to complement onsite systems. In the end, it does not reduce the number of people, but it does change their work. And it provides insight Rockwell Automation can apply to customers.

Benefits of Connected Enterprise

Connected Enterprise provides the logical layers of the systems that interconnect at every stage of the manufacturing lifecycle. There are several results organisations can expect from adopting such a modern production system design.

Firstly, they can benefit from the scalability of SaaS / cloud-native production operations. This allows the company to migrate data and workloads to cloud locations where they can more easily be made available across their network of plants and remote locations, facilitating collaboration and powering business growth.

Secondly, they can realise new sources of value by exploring opportunities in industrial analytics, low-code applications, and connected-worker experiences. This helps to improve the measurability of production and instigate a culture of continual improvement. It also democratises the process of software development, helping different plants and teams to customise applications to their own needs.

Finally, it helps the business build out a design simulation portfolio, utilising the tools and techniques of digital twin development to enable rapid shift from idea to production. This encourages a culture of experimentation and enterprise, boosting the organisation’s innovative potential.

Connected Enterprise changes the way businesses think about industrial automation. It opens the door to new ways of working, allowing greater visibility across processes. This enables the business to capture the value of data and analytics for better, faster decision-making that offers seamless connectivity to spur collaboration.

While there is a wide and varied range skills and expertise involved in designing and customising a platform that cuts across established business divisions, Rockwell Automation is perfectly set up to deliver the Connected Enterprise for customers as an integrated, holistic platform, to help our customers achieve what they need.

In closing Chris said, “We need to recognise the customers’ applications, to help outline their best chances to increase productivity. We have those capabilities here in Rockwell and we are adding more all the time.”

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login