–Mark Gabel, Vice President for Industrial & Aerospace SEA, Schaeffler (Singapore) Pte. Ltd

The world seems to be turning faster and faster. The chain of advancements that followed resulted in the deliberation and restructuring of industrial activities in South East Asia’s (SE Asia) developing economies. The region, once known for its low-level technology, is now a thing of the past. Today’s consumers are more concerned in custom-made products of higher quality with better safety features at a competitive price.

Internationally renowned supplier and development partner, Schaeffler, makes a decisive contribution to the Mobility for Tomorrow. The company is actively helping to shape the rapid developments that are taking place worldwide as part of an approach founded on quality, technology, and innovation.

IMNA sat down with executives from Schaeffler (Singapore) Pte. Ltd in a recent interview; keeping with the company’s Mobility for Tomorrow strategic concept, technology leadership, manufacturing expertise and systems know-how.

Reliability in all components

SE Asia is a powerhouse for the automotive industry and beyond with very attractive perspective for the coming years. The region presents the double interest of having large markets with significant sales

growth potential and important automotive manufacturing hubs to produce for Asia and the world.

Mark Gabel, Vice President for Industrial & Aerospace SEA, said, “We are playing a big role in the SE Asian market, especially in Indonesia, Thailand and Vietnam. Although there is still a big portion of the population

who cannot afford a car yet, mobility is therefore done through motorcycles.”

The dual aspect of certain SE Asian countries create potential and challenge for every global manufacturer. Characteristics such as consumers’ habits, preferences, and income coupled with various levels of maturity in the different markets make a challenging environment to succeed at the regional level.

“Most of our customers are looking for consistent performance, and high-precision components,” disclosed Gabel. “Even in the motorcycle market, certain customers prefer to buy higher quality products that last longer,

rather than going to the cheapest solution. Because sometimes the whole family travels in one motorbike and you don’t want the wheel bearing to fail,” he added.

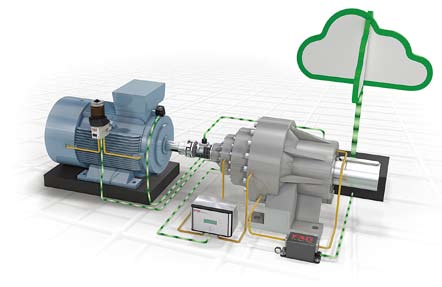

Schaeffler provides bearing supports and system solutions for industrial applications. With the INA and FAG brands, the company have a unique and high-quality range of components and system solutions available.

Not to mention, an extended operating life of machines via highly-developed components and assemblies with durable materials.

INA and FAG components also assist in balancing individual mobility with economy and ecology in numerous other industrial applications. New solutions and products of highest quality are thus continuously

being developed and produced in close cooperation with its customers from the industrial sectors.

Developing and manufacturing lightweight and space-saving components is one of the company’s core areas of expertise. They have produced rolling bearings with economical cold-formed bearing rings, and

develop high-precision components with the lowest movable mass, which can be economically produced in volume.

Manufacturing standard

Bert Rosenheinrich, Director Engineering S o u t h E a s t A s i a , explained they have a certain quality policy at Schaeffler. “That means whatever we produce either in Mexico, Germany, China or Vietnam the quality level is the same. So there’s no different branding.

“Products made in Vietnam do not signify that it is of lower branding or image when compared to those made in Germany. All our products have the same level of quality worldwide. But some of our competitors and few other companies have a different mind-set on that aspect, he added.

Standardisation gives the company not only an increase in speed but also flexibility vis-à-vis market fluctuations. Nearly every Schaeffler product can be manufactured at several locations worldwide. This in turn is the prerequisite enabling Schaeffler to answer the question “Where to produce what?” irrespective of the technical conditions of individual locations, but coming to a decision solely based on the growth in the region. Many of the machines used are built by the company’s in-house special machinery department, and can be easily adapted to various geometries of bearings and other workpieces.

Rosenheinrich revealed, “When you go to our China plant, you can see the exact copy of our German plant. You can find experienced employees, and the same measuring equipment and other processing machines. All of our factories follow an ingenious modular principle not only the machines, but also the entire material flow and the surface layout follow uniform global standards.”

“Therefore, with our globally uniform and high manufacturing standards, we ensure that every customer receives the expected level of quality regardless of whether the customers are in Asia or Europe,” he said.

Price points

The bearing industry has undergone many changes over the past years, including improvements in efficiency, reliability and quality. But underlying all these advances is the relentless pressure to deliver them at lower price points.

Gabel said, “Price is always a very hot topic, especially in Asia. Not everyone knows how much effort goes into creating those bearings. Part of our job as a supplier is to convince our customers to buy what we’re offering, and that means taking the time to explain why it’s worth to buy our products rather than the cheaper alternative. Normally the cheaper ones use a lower grade of material. Products made using lower grade material can work but the lifetime is shorter.”

He added, “The cost of a bearing compared to the whole production equipment is only a small portion, so typically if you explain the differences, the customers are willing to pay more in order to have the efficiency and advantages they need.”

Schaeffler’s objective is to ensure optimum interaction between technology, organisation, and communication. They place high demands on their suppliers. This is because a network of suppliers coordinated both locally and globally with optimised processes and the best-possible quality are important success factors.

adidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login