The weldment is heated to a temperature below the transformation temperature, approximately 1350°F (730°C) for ferritic steels, and held at this temperature for a predetermined amount of time, followed by uniform cooling.

Stress relieving is often used to reduce distortion and to control dimensional stability and tolerances. For example, presses require precise dimensional control and are typically stress relieved after welding. Stress relieving may also be performed to prevent stress corrosion cracking or other deleterious results of residual stresses.

Which electrodes are stress relieved?

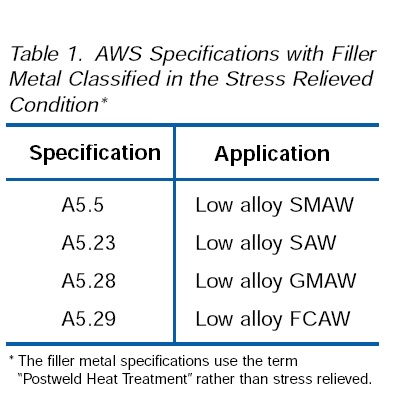

Table 1 contains the AWS filler metal specifications where deposited weld metal can be classified in the stress relieved condition.

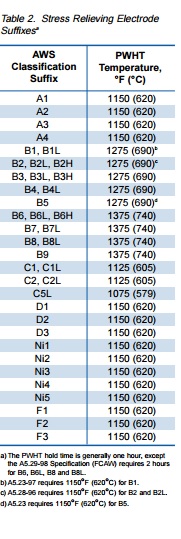

If the filler metal classification includes one of the suffixes listed in Table 2, then that product is classified in the stress relieved condition. For example, Lincoln Outershield 81B2-H (E81T1-B2) is classified with a postweld heat treatment of 1275°F (675°C) for 1 hour. The B2 suffix alone is enough information to know that the deposit is stress relieved. Notice that in Table 2 the stress relieving time and temperature vary for each suffix, and in some cases they vary between the different filler metal specifications. For specific requirements, the filler metal specifications should be reviewed.

In the classification designation for submerged arc, the third character identifies the postweld heat treatment condition: either as-welded or stress relieved. An “A” indicates as-welded and a “P” designates postweld heat treatment. For example, an F7A4-EGNi1 flux/electrode combination is classified in the as-welded condition, while an F7P4-EG-Ni1 is classified in the stress relieved condition. In some cases, the same product can be classified in both the as-welded and stress relieved conditions (e.g., Lincoln LA85/882 is classified as F7A4-EGNi1 and F7P4-EG-Ni1).

Potential problems

Three situations can arise where the “wrong” electrode is used.

• An electrode classified in the stress relieved condition is used in an application that does not get stress relieved.

• An electrode classified in the as welded condition gets stress relieved.

• The actual post weld heat treatment time and/or temperature differ from that of the classification.

If one of these scenarios occurs, it does not necessarily mean that is the result will be a “bad” weld. However, the situation should be reviewed to determine any influence on mechanical properties and quality.

Influence on strength Stress relieving typically reduces weld strength by about 10 to 15%. For example, the tensile strength in the as welded condition may be 80 ksi, while in the stress relieved condition it may only be 70 ksi. Therefore, if an electrode classified in the as-welded condition is stress relieved, the final tensile strength could fall below the minimum classification tensile strength. This situation would create a weld that is weaker than intended.

On the other hand, if a weld is made with an electrode classified in the stress relieved condition and is not stress relieved after welding, then an overmatching strength relationship may exist. This situation is not necessarily detrimental. However, higher strength welds generally lead to higher residual stresses, lower ductility and greater crack sensitivity. In addition, the AWS D1.1 Structural Welding Code–Steel requires that the welding procedure be qualified by test if overmatching strength is used.

Influence on notch toughness

In most cases, notch toughness is increased by stress relieving. If an as-welded product is stress relieved, the notch toughness will most likely go up. However, if the product is classified as stress relieved, and the Charpy V-Notch (CVN) properties are only slightly above the minimum values, this could be a problem if the weld deposit is not stress relieved. In this case, the as-welded CVN energy values could fall below the minimum requirements. Furthermore, excessively high stress relieving temperatures can reduce the measured CVN toughness values. Therefore, during stress relieving care should be taken to control the temperature and time at temperature.

Conclusions

If stress relieving heat treatment is to be conducted, the final weld properties and quality should be evaluated and the filler metal should be one that is classified in the stress relieved condition. The influence of the heat treatment on the weld metal, heat-affected zone and base metal properties should be assessed. Finally, if the heat treatment time and temperature are different than the filler metal classification, then the possible effects of these differences should be evaluated.

1) R. Scott Funderburk. “Postweld Heat Treatment,” Welding Innovation, Vol XV, No. 2, 1998.

2) Copies of the filler metal specifications can be ordered from AWS at http://www.aws.org

Air Jordan XXXII

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login