SPECIALIST in weight filling on both food and non-food markets, Serac Group has also acquired, over the past few years, state-of-the-art expertise in packaging manufacturing and is now producing blowing units. The company is believes PET bottle is a packaging called to develop again, and that fully integrated packaging lines can provide mid-size bottle productions with a long-lasting competitive edge.

Serac has developed the Combox machine range, which associates the group’s SBL linear blower with its renowned rotary weight fillers. This concept has been designed to offer maximum quality and efficiency without any over-sizing of the equipment, and is thus a cost-effective solution for mid-size production.

Combox H2F, blow-fill-cap equipment associating high precision blowing to rotary weight filler for low to medium outputs

On-site bottle manufacturing with the right output

Any manufacturer involved with packaging operations will sooner or later consider producing its own container. If purchasing ready-made bottles seems a natural option for manufacturers who have just started with this packaging, in-house manufacturing offers many benefits as soon as volumes begin to grow and product range expands.

Purchasing plastic preforms instead of blown bottles drastically reduces the transported volumes as well as the risk of having bottles scratched or distorted, while on-demand production avoids wasting money on storage.

In-house manufacturing also gives more flexibility on packaging lines by offering the possibility to produce different packaging shapes or sizes on the same line. Finally, in-house manufacturing provides higher safety against bottle pollution since the blown bottles go directly from the mold to the filling unit.

With its SBL linear blowers, Serac offers all the benefits of on-site bottle manufacturing in a machine specifically designed for low to medium outputs.

The SBL range shows output rates going from up to 18 000 bottles per hour depending on the machine model and bottle size, which can vary from 50 ml up to 5 liters.

PET stretch blow-molding for high quality bottles

The bottle is definitely the packaging that stands for quality, whatever the kind of product (food or non-food) and the distribution channel. Consumers also tend to make this packaging their preferred one, based on the convenience it offers. Bottles are indeed easy to handle, reclosable and shock-resistant and thus adapted to both household and on-the-go use. Enhancing the quality of the product it protects, a bottle is moreover a good solution for manufacturers to stand out from competition in shelves by using original shapes and colors.

When considering on site bottle manufacturing, choosing the right material is an essential criteria. Originally dedicated to water and drinks, PET is increasingly used on other markets such as the dairy, edible oil, household and personal care markets, based on the advantages it offers against glass or PVC for example. These advantages can include the possibility to produce transparent bottles with glossy appearance or original shape, better recycling properties, cost effectiveness of the PET bottle production line.

But more important when it comes to quality, PET has proven ideal for producing lightweight highly resistant bottles. The material bi-orientation achieved through the two-step stretch blow-molding process provides high toughness and resistance to internal pressure, and enables thin bottles to be stacked as high as glass ones.

Serac Blow Linear (SBL): fast and reliable linear blowing units

Having acquired state of the art skills in PET blow-molding over the past few years, Serac knew where the keypoints to precision and repeatability were before the company started designing its stretch blow-molding units. By concentrating its efforts on controlling the heating process of preforms and maximizing time allocated to heating and blowing, Serac is able to stretch light weight preforms up to their limits with an homogeneous bottle thickness and no risk of neck deformation. Ultimate control of the blowing process of SBL units has been achieved by integrating state of the art technologies and proven, long-lasting devices. These include the new generation of NS-IRS heating boxes from Olicorp, Seitz technology based solenoid pre-blowing and blowing valves and automation control from B&R.

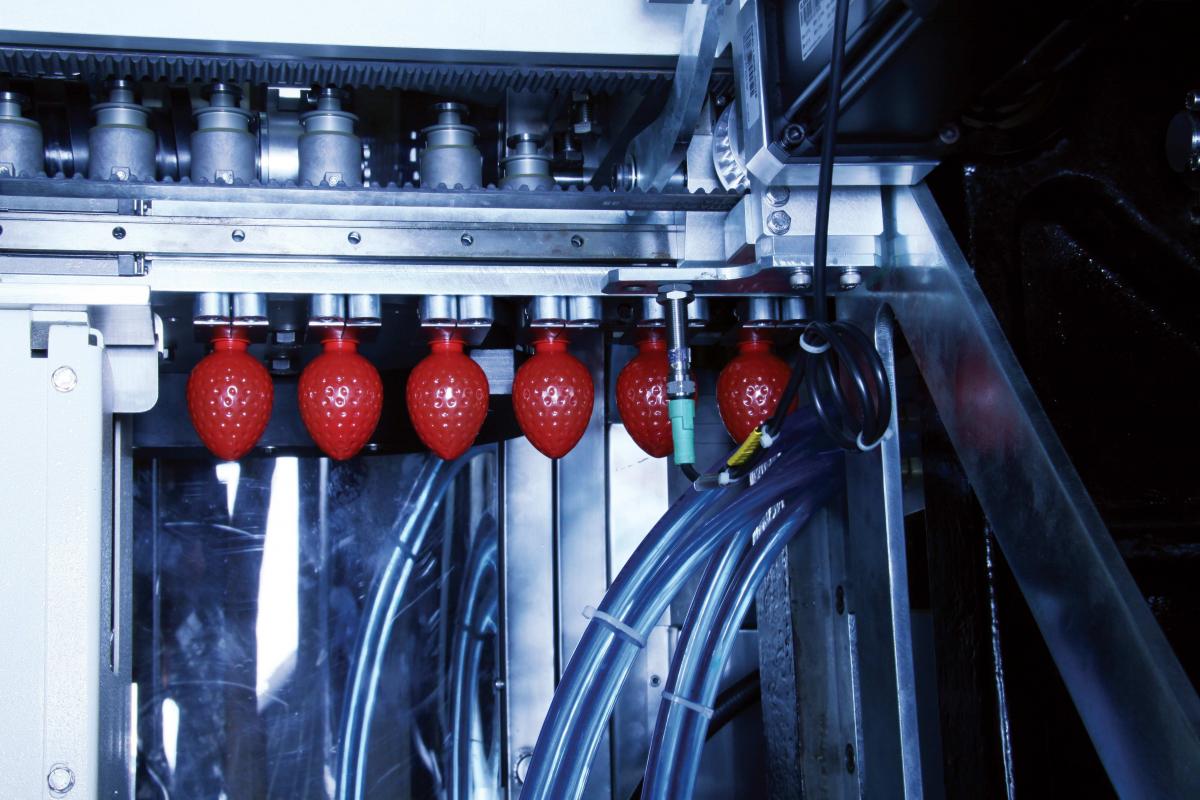

As an example of what Serac’s SBL can achieve, we can quote these 50 g yogurt portions presented in an attractive fruit-shaped flask blown from a PET preform of 2,3 g only with nearly half of the mass concentrated in the neck. The fruit-shaped flask requires an expansion rate of 16 (4 times in both length and width), which is extreme in this industry.

High level of precision in stretch-blow-molding with a 50g yoghurt portion

A preferential heating option is also available to further enhance the versatility of the SBL blowing units. Unlike what is done in the standard process, heat is not evenly distributed on the preform but concentrated on two sides. Preferential heating is used to produce oval bottles (width/length ratio equal or higher than 2), square and complex-shaped containers. The main applications of this specific process are to be found on markets such as oils and sauces, dishwashing and surface care products, hair and skin care products.

Particularly reliable, the high precision linear blowing units proposed by Serac are also highly efficient since they can produce up to 12 000 bottles of 1 liter per hour, with an efficiency rate up to 98%.

Combox: a unique single block blow-fill-cap concept

Under the name Combox, Serac is proposing a unique single block blow-fill-cap equipment associating a high precision blowing unit with a rotary weight filler for low to medium outputs. The net weight filling technology, a specialty of the group for over 40 years, offers great benefits in terms of filling accuracy and reliability, Clean In Place (CIP) facilities and maintenance.

Quality and efficiency of the single block unit are guaranteed thanks to a unique, patented transfer system designed by Serac. Preforms and bottles are always positively transferred and move along the process without ever touching each other. This avoids jams, bottle drops and scratches. The transfer system also converts the sequential motion of the linear blower into a continuous motion adapted to the rotary filler. It is associated with a special filling mode to ensure quick adjustment of the filler-capper to the blowing unit output. At the end of each production batch, both machines communicate with each other to ensure all remaining preforms in the blowing unit are used and properly filled and capped.

Specific transfer system (Serac patented)

Combox units also allow reducing downtime to a minimum, thanks to quick mold changeovers that require 10 minutes of one operator, simplified maintenance operations and the avoidance of production starts and stops potentially associated with accumulation systems.

With a compact and ergonomic design, Combox units enable manufacturers to save the packaging lines footprint comparing a classic packaging line with conveyor and to reduce labor costs since a single person is enough for monitoring both the blowing and filling operations.

With different models of SBL stretch blow-molding machines associated with its complete range of filling units, Serac can propose a Combox concept for a wide variety of applications to answer Japanese market needs. Technical service is ensured by Serac Japan and blowing tests can be easily conducted for packaging qualification in advance of full industrialization.

adidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login