OTTAWA, Canada-based ShapeGrabber is a 3D laser scanning company that was recently acquired by the world's largest vision metrology company, Quality Vision International (QVI). Pierre Aubrey, the president of ShapeGrabber, was recently in town to meet with Kelly Ho, general manager of OGP, which is also a subsidiary of QVI. INTERNATIONAL METALWORKING NEWS FOR ASIA (IMNA) sat down with them to discuss their exciting new partnership, the necessary move towards automation, and the time-saving possibilities with 3D scanning.

IMNA: Can you tell us about your operations in Asia? When did it begin?

Pierre Aubrey: We have been active in Asia for a long time now, more than 15 years. We have several customers in Japan and Taiwan that we've had through long-term relationships with distributors there. Our product focus changed a few years ago and now we focus more on automated inspection.

IMNA: How does the acquisition of ShapeGrabber by QVI fit into the overall ShapeGrabber corporate vision?

Pierre Aubrey: It has a huge impact because we believe that we have a really good product line that can solve a lot of needs of component manufacturers. The biggest thing that we have been missing is the distribution network and that's what QVI brings. They have a huge network of customers in South East Asia and China, and there are other partners in other areas of Asia as well. So it is going to have a lot of impact on our company in terms of visibility and sharing our products with other people.

IMNA: With this acquisition, what are the benefits for the customers in Asia?

Pierre Aubrey: Access to sales and services that is local and in their own language. It can provide them with local support faster than we can from our headquarters in Ottawa. QVI has been in the metrology business for 70 years, and the sales partners in Asia are also very experienced. They can explain the benefits of the ShapeGrabber product and explain how it fits in with all of the other metrology products that are out there.

IMNA: What synergies in your partnership with QVI ShapeGrabber are helping OGP Singapore evolve?

Kelly Ho: Before ShapeGrabber became part of the QVI family, we had already been working with them for three years. We started quite early in terms of 3D scanning because we do see that there is a lot of potential. In Asia, when we look at machines, we tend to look at the technical specifications and focus on accuracy, resolution and pricing. We don't have a strong concept of how 3D scanning can fit into daily inspection. So during the first few years in the market, we had to expose the machine and the idea to people. We found many people that had a lot of parts that were piled up and they didn't have the time to inspect them one by one. This 3D scanning gives them the information they require in much shorter time. But because of our new relationship, there is a lot more information and resources that we can share and it is much easier in terms of cooperation.

IMNA: How involved is the company, from a manufacturing and marketing standpoint, in Asia?

Pierre Aubrey: ShapeGrabber does not have any manufacturing facilities in Asia, all of the assembly currently occurs in Ottawa, but parts are sourced worldwide including Asia. In regards to marketing, it is done through the regional subsidiaries which would be in Singapore, Shanghai and elsewhere. There will be some marketing activities that will happen in Asia through advertising and trade shows.

Kelly Ho: We also have been doing a lot of marketing through magazines and the website. Now, we are focusing on events and we are trying to get the related people involved. We try to let them know how the machines work and what our latest strategies are.

IMNA: What market opportunities or major application areas do you see growing rapidly in Asia?

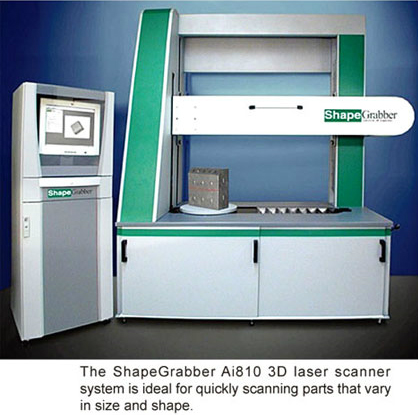

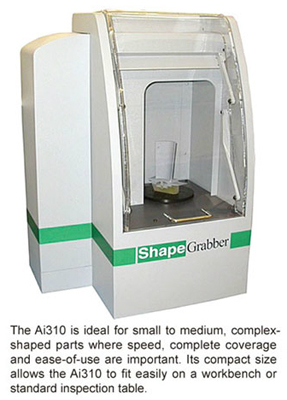

Pierre Aubrey: We see that 3D scanners are being used more and more for regular quality control inspection tasks within manufacturing. It was a new idea just over a decade ago and only very few people were doing this. Now, it is becoming an accepted way of doing quality control. This is because it is so much faster and it gives you so much more data than single-point gathering devices. This is happening in Asia, just as much as everywhere else. Because so much manufacturing happens in Asia, this means that there is a big opportunity for ShapeGrabber in Asia. The penetration of 3D scanners into the overall metrology industry is going to increase at a very fast rate and our products are very well positioned for that because we focus on automation and ease-of-use, as opposed to making it a tool for engineers. We are focusing on allowing people to conduct day-to-day regular inspection.

IMNA: How do you see the needs of manufacturers in Asia changing? How are you addressing these needs?

Kelly Ho: The labour in Singapore is very expensive; you can't always have lots of people working on measurements. We are going in the direction of more automation. They can now get the information just by pressing a button, and their personnel can concentrate on doing other things. It is just the cost that might be hindering people from buying equipment right now. Our job is to let the customers understand the ease of using ShapeGrabber as part of their measurement routine. You can get information in a few minutes that would take much longer with other equipment. Customers see the value in this.

Pierre Aubrey: It's not an Asia-specific thing. People everywhere are trying to find a more effective way of making things, measuring things and going away from more labour intensive methods. A reason why a lot of Asian-based economies started getting involved in manufacturing is because labour was not expensive. But over time people realise that it's not a sustainable advantage because labour rates rise and after a point you don't want to just keep catching up with the more advanced economies. More and more there are a lot of Asian companies that are able to produce goods that are of higher quality and faster. It's not enough just to import traditional machines from Germany or the USA, they'll need to start investing in new technologies. There is no reason why Asia can't adopt 3D scanning faster than, for example, Europe.

Kelly Ho: Some people are even using this technology for things other than industrial scanning.

Pierre Aubrey: There's a lot of talk in using 3D scanners in conjunction with 3D printers - to scan something with the purpose of printing it. A lot of the focus is on consumer applications and a lot of people do this because it's a fun thing to do and it might be a hobby for them. For example, they might have a part around the house that's broken, then they'll scan it and print another one. That's interesting technology, but it's not the part of 3D scanning technology that we are involved in. We are really focused on quality control and industrial metrology.

Shop Womens Socks - View the Large Range

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login