The recent EuroBlech exhibition appearance ran under the motto "World Class Manufacturing". This reflected what Bystronic Group is presenting with comprehensive program of new products and services, which enable them to sustainably optimize their customers' processes and gear them towards success.

In a recent interview with Interview Alex Waser, CEO of Bystronic Group, INTERNATIONAL METALWORKING NEWS FOR ASIA (IMNA) got valuable insight regarding the company’s Asian market particularly, China market including laser technology and its impact on sheet metal fabrication.

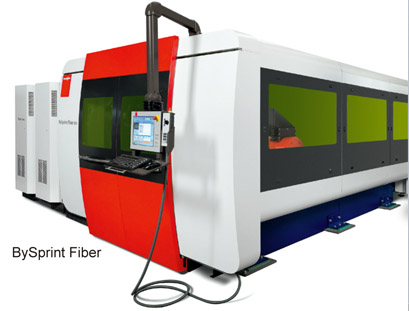

IMNA: One of Bystronic products is the laser cutting system, specifically fiber lasers. I understand you are now developing and manufacturing fiber lasers in China. How would you compete with the local companies in that space who have their own fabs and local personnel’s in the region to optimize products?

Alex Waser: China is a very important market for us. Here, we see considerable potential for further growth in the future. With our "World Class Manufacturing" program, we offer our customers comprehensive solutions for all the process steps relating to cutting and bending. Thus, as a full-range provider, we are able to sustainably gear our customers' production processes towards success. Moreover, for our customers in Asia, we also combine many years of know-how in the local market together with Swiss precision.

IMNA: The laser technology is being touted as the next new platform to hit the metalworking industry. What impact do you think this will have on sheet metal fabrication?

Alex Waser: The fiber laser remains an unbroken trend. At Bystronic, we recognized the potential of the fiber laser at a very early stage. Hence, we adjusted the focus of our development accordingly. This has allowed us to develop sufficient innovative drive in the field of fiber laser technology, but also in the field of CO2 laser technology. Both technologies are indispensable for the market.

IMNA: Do you see manufacturers of metal products having the same or a different set of requirements when it comes to laser cutting machines? How different are the expectations for price points?

Alex Waser: In the field of sheet metal processing, we certainly see diverse segments amongst our customers. Our wide-ranging portfolio of products and services enables us to offer customized solutions for these diverse requirements.

IMNA: What challenges would you like to be working on, or what’s going to keep you interested in this industry for another 10 years?

Alex Waser: Our "World Class Manufacturing" program will continue to be a topic for quite a while yet. Because when we examine all the processes related to cutting and bending, we still see many possibilities for improvement. In addition, our customer's demands are naturally also always changing. Gaps are always opening up anew, which we will continue to close with innovative solutions.

IMNA: Are there emerging technologies that Bystronic is uniquely positioned to provide or support?

Alex Waser: Bystronic is a full-range provider for cross-process solutions for all the processes related to cutting and bending. Let me illustrate this using an example: We not only provide our customers with a high-performance cutting or bending machine. Nowadays, this is not enough. Sheet metal processing consists of many individual stages. It begins with preparing an offer, continues with programming the cutting and bending processes, and ends with the delivery of the finished product. As a provider, we master all of these stages and can release our customers' full potential for optimization at every stage.

IMNA: My question consists of two parts. As the CEO for Bystronic, what areas do you see as requiring more focus, and what are you bringing to the company that will ensure you meet these objectives?

Alex Waser: We constantly work on improving our technologies. This is true for all our product groups. And we are searching for new trends so we can continue to shape sheet metal processing with our innovations in the future.

IMNA: What synergies in your dealings with Asian customers are helping the company evolve and be in a stronger position in today's fluid economy? Where do you see the greatest opportunities for growth?

Alex Waser: We work very closely with our customers in Asia. High demands are placed on us here. This challenges us as a company. And it helps to continuously develop our competitiveness further. In dialogue with our customers, we learn a great deal about the local requirements. This leads us to new solutions, which we may never have thought of without our customers.

Geographically, we expect strong growth particularly in Asia and America.

Air Jordan XIII Melo PE

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login