Modernisation continues and product lifecycles aren't what they used to be. Competition is fiercer – and comes from more unexpected sources – than ever. As manufacturers look ahead to 2016 and beyond, some of the biggest themes shaping the future of their supply chains will arise from the challenges they face today.

Pete Carrier, Senior Vice President and Managing Director for Asia Pacific, Siemens PLM Software shared his thoughts with IMNA about the manufacturing space in 2015 and 2016 including technologies changing the paradigm.

Highlights of 2015 in the manufacturing space

2015 saw the markets within the Asia Pacific region evolve away from low-skill and low-cost production. The manufacturing climate saw several contractions across countries such as China, Korea and Singapore – and it is forecasted that the situation will not improve anytime soon. However with the implementation of the ASEAN ICT Masterplan in 2015 and the ASEAN Smart Network Initiative, both programs transitioned into a “smart region” via the enhancements of technological infrastructure and facilitating the deployment of IoT technologies.

The past year also saw improved resolution in 3D printing and the ability to print in new materials. It is expected that there will be increased affordability in the upcoming year, addressing complex issues within the healthcare sector particularly. Given the immense benefits they offer to manufacturing organisations, many companies are turning to these solutions in order to overcome the current business climate.

Moving forward, the region will increase capitalisation of the ASEAN Economic Community (AEC) which will enable greater access to markets and freer flow of goods, services and labour. With ASEAN’s efforts to lower barriers for organisations to regionalise, it is timely for businesses to upgrade their capabilities by investing in smart technology or contemplate on plans for regionalisation.

Sustaining competitive advantage

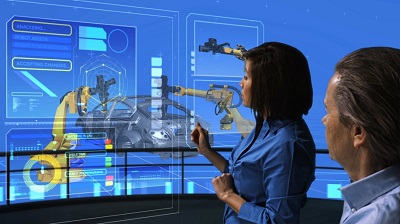

Through realising innovation, organisations will be able to stay ahead of the competition. A model-based enterprise will help develop smarter products with additional dimensions of connectedness and cognitive capability. This simply means the realisation of automation and production in the Digital Enterprise for which digitisation is an approach to innovation. With this, manufacturing organisations of today are better equipped to confront complex business risks and disruptors of tomorrow.

In order to stay relevant and competitive, organisations are recommended to groom three types of talents – 1) workers with deep analytical skills to execute big data studies that will provide invaluable insights on consumer demand that will benefit metalworking, 2) managers and analysts to examine these studies and make them into smart, actionable insights, and 3) supporting technology personnel to enable execution based on these insights.

Smarter decisions will help build the right product by reducing manufacturing costs, increasing quality performance and enable more frequent development of complex products done right.

Major manufacturing changes in 2016

Digital business transformation for manufacturers will continue to evolve, with the supply chain and logistics as one of the core value drivers. Organisations will build towards the “second pillar”, becoming entirely digitalised, spurring on competiveness from countries such as China and India with their “Make In India” and “Make in China 2025” initiatives. And with China’s "Internet Plus" initiative announced in March 2015 as a driving force, many conventional businesses will connect to the Internet initially, followed by digitalisation of IT systems, to drive competitiveness.

3D printing and robotics will continue to gain momentum in 2016, with accelerated product development cycles and rapid prototyping, form and fit testing. In a report conducted by Wohlers Associates, the worldwide 3D printing industry is now expected to grow from $3.07B in revenue in 2013 to $12.8B by 2018, and exceed $21B in worldwide revenue by 2020.

Moving forward, Product Lifecycle Management (PLM) will play a vital role in all verticals, given the rise of digital integration that will require software to align all divisions together. Siemens PLM continues to invest in software solutions to realise innovation and power customer’s digital enterprise move from conceptual to real, connecting virtual development and production planning with the real production environment and lifecycle support. How manufacturers merge both these virtual and tangible assets will become the essence of innovation in the future.

For IMNA, the change will be for manufacturers to improve their entire supply network further than the four walls of their own enterprise. It's particularly significant as more production takes place at contract manufacturers, and more finished products are shipped to more markets around the globe. Greater agility requires end-to-end planning, rapid time to market, and responsiveness versus cost.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login