With two China subsidiaries, SD has developed an agency network in over 45 different countries and has been a pioneer manufacturer of metal coil stamping, processing, feeding machinery since 1983. Over the past 35 years, SD has not only built its strengths in coil stamping industry and coil stamping automation machines but also developed coil slitting line, high speed cut to length line, and press blanking line and various kinds of coil stamping, processing machines for different applications.

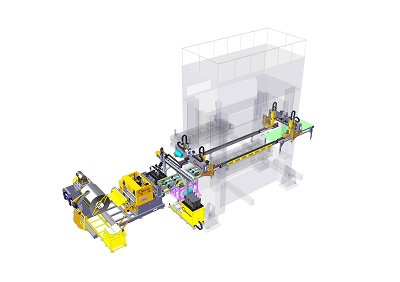

SD produces varies types of metal stamping machine solutions to satisfy different customer requirements. For the coilfeeder and transfer press system, it integrated two systems so that customers can process mass production and small batch orders on the same press line. Customers can also choose to use coil material for progressive stamping for mass production orders, whilst metal blank material can be used by destacker and press transfer systems for multi-station transfer stamping.

Shung Dar's Factory

"Integration of the coil feeder and transfer press lines helps customers to boost their productivity drastically and gives them more flexible production options, enabling higher value returns on the same machinetool investment. All SD systems are tailormade, according to customers’ actual requirements. High speed and high stability of production are the key strengths and the core value of our manufacturing principles," according to Shung Dar.

"More and more automation applications are developing for the coil stamping and processing industry, but the key factor now is how to integrate them all and provide a turnkey solution to clients to increase their production competitiveness while reducing the amount of investment. Here at Shung Dar, supported by our manufacturing expertise and R&D activities, we are doing this for our customers," it added.

Shung Dar with client

In 2014, Shungar sold its first completed blanking press line integrated with coil feed line and high-speed electro-magnetic stacking system to the largest automotive stamper in Thailand. It was a heavy-duty machine with highly automated auxiliary devices for both coil feed and blank stacking operations. SD received several enquiries and orders for the same production line in the years that followed. Further cooperation with Taiwan; Germany; American and Japanese press manufacturers has enabled SD to broaden its product sales network and provide its services to a wider market.

Meet Shung Dar at EuroBLECH 2018 in Hanover, Germany (Hall 27, Stand C156) or at TIMTOS 2019 in Taipei, Taiwan (Hall 1, Stand C0310). For more information, visit www.shungdar.com.tw/en.

Follow Shung Dar on YouTube:

Nike Zoom Live 2017

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login