SIMPLEX Hydraulik’s MLC 2011 vertical ladle milling unit simplifies the relining of monolithically lined casting ladles without pushing up refractory and waste disposal costs.

The unit uses a controllable milling head to remove fused refractory material and baked-on slag from the monolithic lining on the inside wall of the casting ladle. This ensures the inside wall is “white” and that the new refractory concrete can bond strongly with the remaining refractory layer. This likewise avoids removing any material that is still in good condition. The milling head, which is always accurately positioned relative to the ladle, can be moved to any position of the lining automatically or manually by remote control.

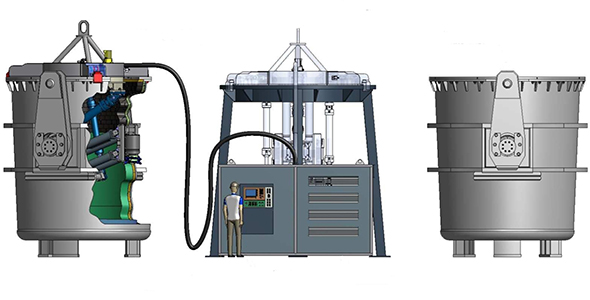

Simpex MLC 2011: The ladle milling unit is lifted by a bay crane from the holding frame (shown in the middle) into the casting ladle

Andreas Berendt, managing director of Simpex Hydraulik GmbH, said the system will not only save on material and disposal costs but will also eliminate strenuous and hazardous work in a steel plant.

The entirely automatic process reduces operation time while ensuring a uniform removal of the fused refractory material. With the use of the milling unit, the amount of wrecked material, transportation and disposal costs, and refractory concrete consumption are also reduced because the system does not remove more material than necessary. Upon completion of the milling, the inside walls are visually inspected.

Further, compared with manual wrecking, the ladle milling unit prolongs the life of the permanent lining because it is subjected only to pressure load. The process does not result in cracks and brittleness.

The automatic process also reduces personnel requirements and takes approximately one hour to be completed. Afterwards, the milling unit will be lifted into the provided holding frame or into the next ladle to be milled.

The ladle milling unit was developed with Hackenberg Ingenieurgesellschaft. Simpex Hydraulik said the design phase has been completed and the first prototype will be built shortly.

The first unit, which was designed for casting ladles with filling weights of 80 to 160 t, comprises the milling equipment proper, a holding frame and a container. The last accommodates the hydraulic unit, including the tank and the controls.

adidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login