Manufacturers of medical, aerospace, prototype and complex multi-face parts have long understood the positive impact that 5-axis machining can have on productivity and quality, simply by consolidating operations. With increasing demand for small-part 5-axis machining, many companies are adding aftermarket 5th-axis rotary tables to 4-axis machining centres. However, these 5-axis retrofits frequently offer less rigidity and pose several challenges in cable interface management. Dave Ward, horizontal product line manager at Makino said that when looking for a small 5-axis machining solution, companies are typically limited to single-pallet-load vertical machining centres.

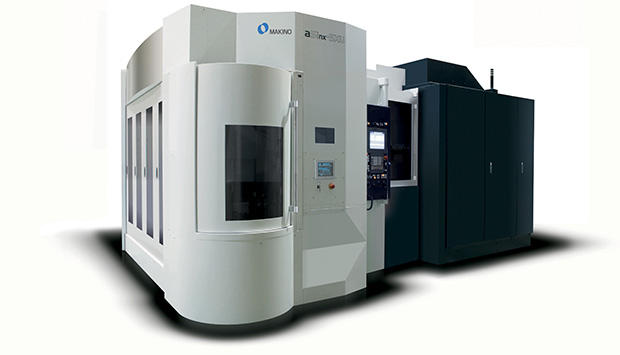

Makino’s a51nx-5XU 5-axis horizontal machining centre raises these capabilities to a new level, building on the quality, durability, and reliability of the nx-series next-generation horizontal machining platform. With a newly designed 5th-axis table and work-pallet magazine, this new machining centre enables manufacturers of complex parts to obtain the highest levels of utilisation and efficiency.

“The a51nx-5XU stands apart with its horizontal orientation, integral cast 5th-axis table, and integrated workpiece automation. Together, these features provide for a highly productive, highly reliable multi-axis machining solution that eliminates re-cutting of chips, stack-up errors, and challenges of 5-axis part loading. It’s the perfect blend of capabilities for the manufacturing of rotating cutting tools, aerospace, medical and prototype components,” comments Dave Ward.

Integral automation efficiency

Traditionally, one of the biggest challenges associated with 5-axis part production has been automated capabilities. This is why Makino designed the a51nx-5XU with a unique work-pallet magazine (WPM) that simplifies pallet changes in horizontally oriented 5-axis applications, and facilitates unattended operation for more value-added labour demands.

The WPM takes the place of a traditional horizontal pallet changer, providing manufacturers with automated load/unload capabilities for maximum machine utilisation. This technology follows a similar design to that of Makino’s proven matrix tool magazine, ensuring quick and reliable transfer of workpieces between magazine and machine worktable. The standard WPM offers storage capacity of 22 different workpieces with sizes up to 300 mm in diameter by 300 mm tall. An optional, larger capacity WPM provides storage of up to 58 workpieces with diameters up to 200 mm. Parts are mounted directly to the 50-taper dual-contact tool holders (BBT50) and stored in the WPM matrix. This capability makes the a51nx-5XU an ideal solution for continuous, unattended manufacturing in both high-mix, low-volume and low-mix, high-volume production environments.

The WPM system includes a dedicated work-setting station (WSS) for loading and setup operations, providing convenient and ergonomic operator access. A nearby work data management panel allows operators to process data defined per pallet and manage work schedules. Priorities can be set and changed for each pallet, helping to accommodate for engineering changes or urgent one-off part orders. For advanced levels of scheduling control and machine networking, the a51nx-5XU can also be equipped with Makino’s MAS-A5 control system.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login