Sonderhoff recently launched a 3-component Dispensing Cell SMART-L/DM 403. This low pressure mixing and dosing machine, thoroughly modular constructed, is adaptable to various production concepts. The thin layer degassing for complete air evacuation of the potting material in the pressure tanks is one of the new features of the machine. This degassing method from Sonderhoff results in a crystal clear potting transparency free of air inclusions.

LED technology rapidly gains major shares in the lighting market. Every 6 to 8 months a new LED generation emerges. For protection against moisture, water, dust and other weather effects as well as for temperature and vibration stability LEDs are mostly encapsulated with 2-component casting resins based on polyurethane or silicone. This affects long durability of LEDs, for instance, in weather resistant LED Arrays for illuminated advertising, street and tunnel lights or information screens.

Sonderhoff Chemicals is a manufacturer of potting and foam seal material systems on the basis of polyurethane or silicone, especially for the foam sealing of housings for lamps and electronics and in particular for the encapsulation of LED lighting.

At Fakuma, Sonderhoff demonstrated the potting of flexible LED-stripes with a transparent 2-component polyurethane casting resin system from the product family Fermadur® using the new 3-component dispensing cell SMART-L/DM 403 with thin layer degassing. The air evacuation of the potting compound results in a crystal clear potting transparency free of air inclusions and streaks. Opacification and as a result deviation from the ideal LED light distribution caused by air inclusions will be avoided. With this bubble-free LED encapsulation ingress protection classes up to IP67 and an optimal lighting effect can be reached.

The transparent or opaque LED potting systems Fermadur® from Sonderhoff do not become yellow after a time. Using aliphatic isocyanate they are highly resistant against ultraviolet radiation and therefore have a very good light transmission of up to 89%. Unlike plastics, as for instance PC, PS or SAN, Fermadur® clear potting compounds have the resiliency to return to their original undamaged condition by a "self-healing effect" on scratches and cracks which occur under mechanical load. Thus, the transparent LED potting retains its constant light transmission this technology is also suitable for demanding surface coating applications.

Process reliable potting application

Besides LEDs electronics and electrical elements are also casted with the Fermadur® potting systems on polyurethane basis for protection against moisture, dust, mechanical load and other environmental impact. The potting systems from Sonderhoff are designed for various applications and according to requested properties like, for example, different hardness, material density, temperature resistance, mechanical stability and processing parameters like viscosity, pot life and tack-free time. For potting of electronic elements the customer can choose between different colors. However, for optically attractive LED solutions transparent or opaque potting systems are used.

Ingress protection classes up to IP67 are achievable depending on the part construction, so that external applications, for example swimming pool lighting, are possible. For tunnel lighting in non-explosive areas, the Fermadur® potting systems from Sonderhoff are adjustable flame-retardant, so that they pass the testing acc. to US fire protection classes UL94.

The application of industrial parts occurs economically and on a high level of process reliability with the dosing technique “Formed In-Place“(FIP) using semi or fully automatic low pressure dosing and mixing machines from Sonderhoff Engineering.

Due to a good flow rate the polyurethane based potting compound even dispenses into remote corners of complex parts, equally distributed and full-surface. Using the thin layer degassing method air inclusions in the potting material will be avoided. Several LED series of diverse parts or shapes can be casted with the same potting product processed on a mixing and dosing machine.

Flexible LED-stripes are encapsulated in a two-layer application process, first with a transparent potting and after curing in a second step covered with an opaque potting which provides an optimal light dispersion. Both potting layers are UV-resistant. Although LED light generates much less warmth as traditional incandescent light bulbs, it is essential that protective encapsulations have a high temperature resistance. It is thereby possible to cover a wide range of different applications and operating conditions.

Low-pressure mixing and dispensing system

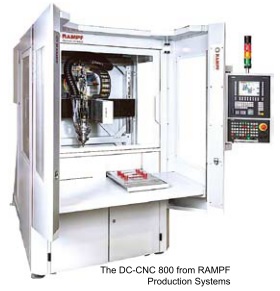

RAMPF Production Systems introduced DC-CNC 800 low-pressure mixing and dispensing system for 2D and 3D application of casting, sealing, and adhesive systems. With the DC-CNC 800 low-pressure mixing and dispensing system, RAMPF Production Systems is presenting the perfect solution for users requiring a compact machine construction without compromising on control technology.

Featuring an integrated material preparation system, the machine has the capability to be fit with optional piston and gear pumps. Further advantages include the CNC Siemens Sinumerik modular control system and integrated process control for continuous monitoring of pressure, fill level, and speed.

Standardised operating concepts for sliding tables, rotary index plates, and conveyor feeds

The system can also be optionally equipped with a high-pressure rinse agent recycling and water rinsing systems as well as numerous other automated equipment components depending on the application in question.

Further features include standardised operating concepts for sliding tables, rotary index plates, and conveyor feeds. The high-quality dispensing system is flexible in its programming and has optional interfaces for all common manufacturing execution systems.

“The DC-CNC 800 has also been fitted with larger tanks, enabling small containers to be fully filled in a single step,” explains Hartmut Storz, Director of Sales & Marketing at RAMPF Production Systems. The larger tanks improve material processing, thus ensuring more material-friendly homogenisation and faster degassing.

In addition, the DC-CNC 800 can be fitted with the MS-C mixing system for dispensing rates of 0.1 g/sec and higher, and the integration of vacuum barrel presses for gap fillers is also possible. “Accessibility has also been significantly improved for maintenance work on the piston and gear pumps and controls,” Mr. Storz pointed out.

The DC-CNC 800 is also used, among others, in the electrical industry, where it ensures exceptional process reliability when applying highly-filled heat dissipation materials to electronic assemblies.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login