Speed, accuracy, and safety are basic requirements in packing/packaging food products. Depending on a manufacturer’s specifications, these requirements are easily fulfilled with the combined use of weighers, inspection machines, labellers, packing systems, and other equipment. Continuing developments in automation also enhance simplicity and ease of use that manufacturers can expect from the latest machines.

Being able to partner with a packaging company that offers complete lines and turnkey solutions can be convenient for food manufacturers especially as their production grows.

Smart Weigh Packaging Machinery Co., Ltd., a company based in Zhongshan, China, offers these machines, and quite an extensive range of packaging equipment for just about any kind of product. It can provide automated systems for weighing, packing, labelling, and handling of food as well as non-foods.

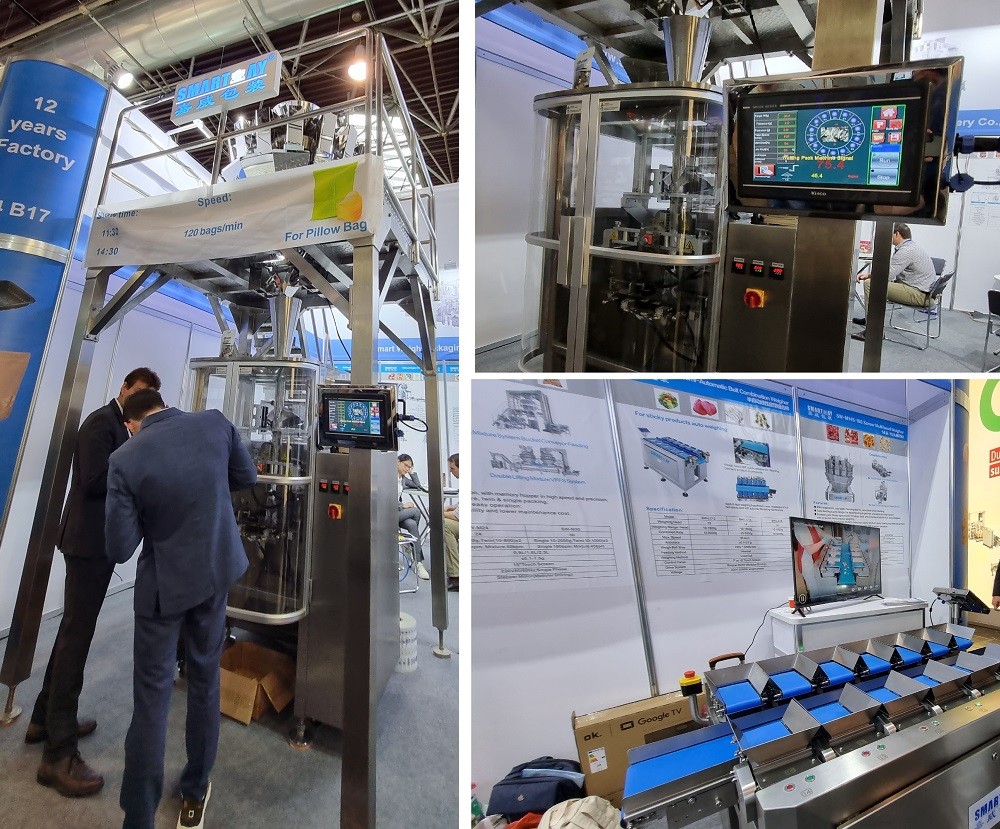

Multihead weigher and packing solutions from Smart Weigh

Established only in 2012, Smart Weigh has quickly expanded its capabilities, product range, and now exports to over 200 countries. Aside from a facility in China, it has a base in Spain for handling parts and supplies, machine installation, and after-sales service for its customers in Europe. Its R&D team can handle ODM.

According to Marketing Director Hanson Wong, packing machines for ready meals are popular in Asia, while machines for packing fruits, nuts, candy, and chips are in demand in Europe.

Smart Weigh ensures its machines are equipped with fully automated technology. Its vertical packaging units, form-fill-seal machines, and premade bag packing machines are ideal for products like tea, dried fruit, frozen food, nuts, and all kinds of snacks.

The company’s robotic case packing line solutions can be integrated into other existing production lines. Its customisable multihead weighers and packing machines are designed to weigh fresh, frozen, and dry foods.

A high-speed bagger that runs 120 bags per minute is among Smart Weigh’s top of the range.

Another design from Smart Weigh is a complete automated food packaging line that weighs items and packs up to 3,000 trays in an hour. The speed may be impressive, but the real benefit is in labour and cost reduction. The line will require about three operators, and investment can be recovered within two years, according to Mr Wong.

Smart Weigh also offers a machine for noodle manufacturers that weigh wet noodles before these undergo the drying stage. Mr. Wong explained that manually operated lines for noodles would require about 20 workers, whereas an automated line can be managed by three. Machines can also run 24/7 with minimal supervision. Within a year, manufacturers can recover their investment in noodle machines.

With automated lines such as these, Smart Weigh is receiving attention from major companies, including a high-speed train company in China that requires equipment that can handle ready meals, and a company in Singapore that is planning to build 100 factories for school lunches.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login