Kurimoto, Ltd: 1600t forging press with servo drive system

Kurimoto, Ltd develops and builds plants and machinery for public and industrial infrastructures. The company has a global reach and has traditionally targeted markets in Japan, China, India and Southeast Asia.

The company dates back to 1909 and is involved in a broad range of activities. From water and power supplies to industrial production and manufacturing processes, as well as public transportation and pharmaceutical plants, the company’s solutions cover a wide range of industries and processes.

This also applies to the metalworking sector where Kurimoto, Ltd also supplies forging presses and forming presses. The main customer for this machinery is the automotive industry. But other industries have also been using Kurimoto, Ltd presses for decades - until now, conventional mechanical presses with flywheels.

New design with servo drive

With the development of its servo forging press in 2014, Kurimoto, Ltd launched an innovation process that focused on servo technology. Initially, the company built two presses with servo drives. The firm cooperates with Siemens – more precisely with Yaskawa Siemens Automation & Drives, in drive technology and press control systems, as one example.

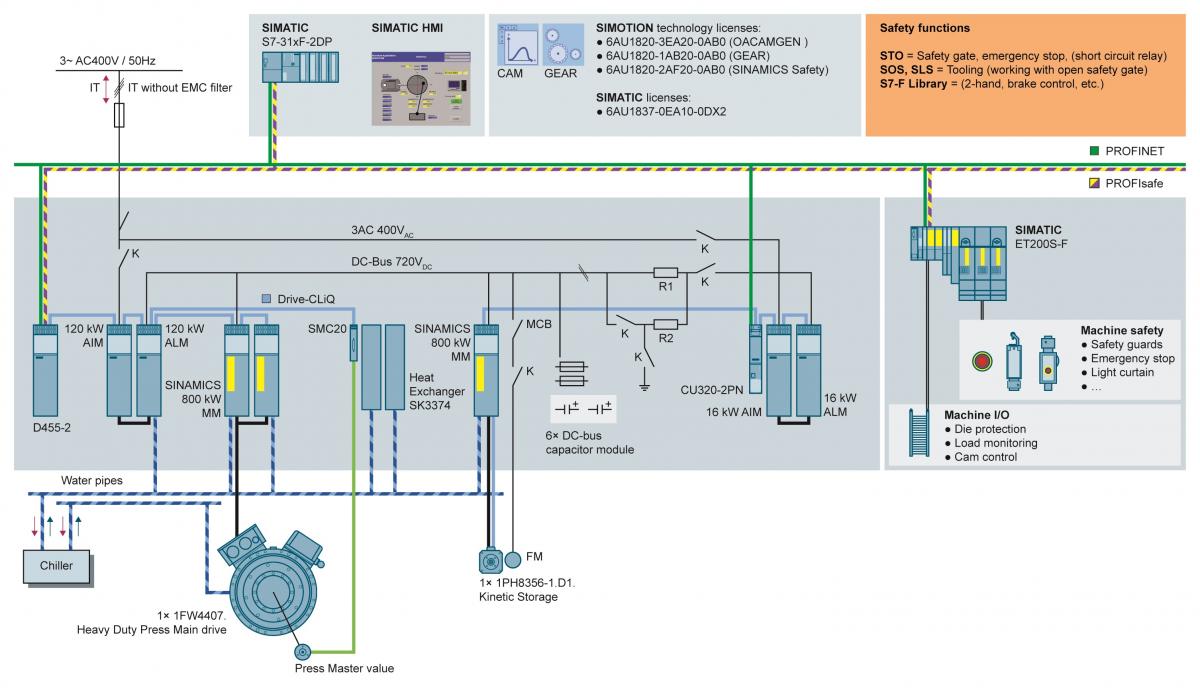

The presses are rated for 1600 tons and 2000 tons. Mechanically speaking, the machines are traditional connecting-rod presses where the excentric does not require a flywheel. It is driven directly by one of the most powerful Siemens torque motors, a water-cooled Simotics 1FW4 heavy-duty unit with a peak output of 1.5 MW. The characteristics of the motor are just one reason for Kurimoto, Ltd’s cooperation with Siemens as an automation partner on this project. High rated power, generous overload capability and plenty of torque, even at low speeds - these were the essential requirements for providing the forces needed for these huge forging presses.

Time savings: servo enables individually optimized motion profiles

The drive unit provides the extreme acceleration and also the precisely controlled guidance for the huge mass of ram and die, which are very heavy and have to be moved. The ram is accelerated dramatically at the beginning of the cycle. To save time, it traverses the space between the opened die and the workpiece at maximum speed. Prior to actually penetrating the workpiece, the press decelerates to reach the forming velocity adapted to the flow characteristics of the material, the shape of the die and the required workpiece quality.

The force and motion profiles of the high-performance servo drive can also be precisely modified to influence the forming process as it takes place. Finally, the ram is returned to the top dead center at maximum velocity, which increases the workpiece handling time even more.

This enables faster cycle times without shortening the time needed to remove the workpiece and place a new blank into the press. The servo technology results in a higher cycle rate with the same or even greater process reliability.

A servo forging press as a test and demonstration machine

Kurimoto, Ltd delivered its second servo press to a well-known production company in Osaka. The first of these new forging presses is operated by the machine manufacturer itself. It serves as a testing press to evaluate the feasibility of forming operations and to optimize machining processes for industrial customers.

Intermittent or continuous operation

Both presses are currently being operated intermittently. However, the automation concept also supports continuous operation with slow motion through the top dead center. This control strategy makes it possible to boost energy efficiency even more.

Energy management with capacitive and kinetic buffers

The servo presses are equipped with a high-performance energy management system. The system takes advantage of the interaction between the acceleration and braking phases during the cyclic process to prevent the load peaks of the big servo motor from having a negative impact on the power supply.

When the press is powered up, a large induction motor is accelerated from its idle speed to a high-speed. The rotating mass of its rotor stores kinetic energy, which flows back into the DC link of the Sinamics S120 drive system when it brakes in the generator mode. Further, the DC link of the drive is equipped with six Sinamics capacitor modules to store energy. The energy needed to accelerate the ram and die is delivered primarily by the flywheel motor and the capacitor bank. When the press decelerates, the main motor operates in generator mode and feeds energy back into the DC link of the Sinamics drive system, which charges up the capacitor bank and brings the flywheel motor back up to speed.

High performance, small connected load and low consumption

Only the forming energy and power losses of the machine are drawn from the line supply, and the power draw is evenly distributed over the cycle time. This means that despite its 1.5 MW peak drive power rating, the press has a connected load of just 120 kW and thus only requires a power supply for this rating. The cross-section of the connecting cables is also correspondingly small, which makes electrical installation of the press easy and inexpensive.

The low peak load and active infeed at high efficiency and low harmonic content reduce power costs.

This energy management system has already impressed many potential buyers and is a key sales argument for Kurimoto, Ltd.

Plug-and-play control cabinet from the automation partner

The servo motor and power units of the converters are liquid cooled, enabling efficient dissipation of waste heat, which can be used cost-efficiently to treat industrial water or as process heat. Furthermore, the liquid-cooled drive system eliminates the need for control panels to have high-maintenance air filters, creating an overall very robust industry-standard solution. Kurimoto, Ltd sourced the control panels using pre-installed and pre-tested drive technology from the Siemens Systems Engineering Plant in Chemnitz. This helped to reduce the installation work and speed up commissioning.

Rapid implementation: comprehensive system software - efficient engineering

The Kurimoto, Ltd servo presses use Siemens SimoPressServo system software. This software meets all of the usual requirements for the control, operation, maintenance and diagnostic functions of the presses. With this range of functions, the machine manufacturer’s developers can devote their full attention to the specific mechanical and customer-related functions. This approach ensures efficient engineering and provides added project reliability - with SimoPressServo, most of the user software is already supplied in a quality-assured form.

Promoting technology and productivity

Kurimoto, Ltd has combined the benefits of a forging press with energy management and a servo press with freely definable ram motion. This helps the machine manufacturer’s technology experts to determine the best possible forming process for a given component.

During operation, freely configurable motion profiles allow the time required for infeed and retraction of the die to be reduced. Further, these profiles allow the forming process to be optimized. Despite the shortened cycle time, there is enough time for workpiece handling. As a consequence, with the same level of process reliability, a higher productivity is achieved - both in terms of achievable quality and throughput.

The Siemens drive and control system technology provides access to an advanced energy management system and system software with complete basic functionality and facilitates efficient engineering for the machine manufacturer as well as streamlining project performance. In the company’s international business, a global presence, widespread acceptance, and the performance of the automation partner are additional sales arguments. End users can be assured of outstanding service and fast availability of spare parts for all of the drive components.

For Kurimoto, Ltd, the flexible, in-house try-out servo press is a key building block for taking forming technology to the next level with its customers.

The 1.5 MW Siemens torque motor coupled with the press.

State-of-the-art forming technology: liquid-cooled drive technology, energy management and press control from a single source.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login