To ensure this market demand is met, Sandvik Coromant has invested many decades and considerable resources into continuous research, development and testing of parting and grooving technologies. Conducted in close unison with customers, each technology is developed to bring direct benefits to the end user.

Solving the long overhang machining challenge

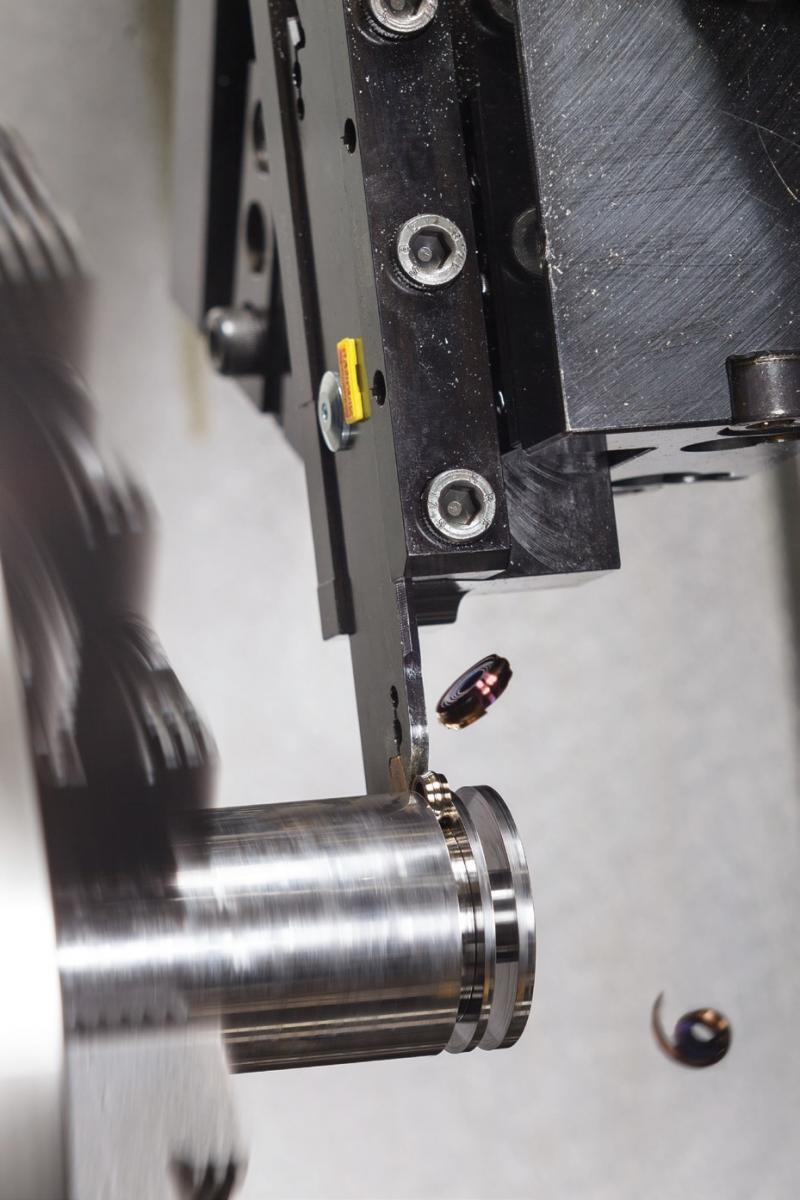

One of the main factors in all parting and grooving operations is to minimise tool overhang wherever possible. However, when parting-off large diameter bars, long overhang is unavoidable, if there is a need to reach past a sub-spindle, for example. This means the tool has to compensate for the inherent instability of the operation, offering the capability for safe, reliable machining that is also highly competitive. CoroCut QD, a parting-off tool system of inserts, holders and unique plug and play coolant adaptors has been developed from this market demand, allowing users to apply tools confidently without the tendency to under-perform the operation in the name of “just-in-case” security.

Customer requirements were prioritised during the development phase. Aside from process security factors such as rigidity, strength and excellent chip control, the focus was on extended tool life, ease of use, high surface finish, and optimised productivity to ensure low machining cost per cut. Also, there was a clear requirement to develop an easy-to-select yet comprehensive programme covering as many applications, machines and materials as possible.

The insert edge matters

In parting-off there are three stages of the plunge: the main long cut through most of the bar; the approach towards the end of the cut; and the short stage just before reaching the centreline. With regard to inserts, the strength of the cutting edge, resistance to built-up-edge (BUE) and the durability of the coating are all critical factors. However, this also has to be combined with achieving insert grade capability for high cutting speeds and feeds during the main plunging cut.

Dedicated inserts for parting-off and deep grooving have been developed with new geometries for all materials, including chip breaking where needed and wiper cutting edges for enhanced surface finish. Inserts have also been designed to make optimum use of the precision coolant jets that are applied as part of the CoroCut QD concept. This helps ensure that lower cutting forces are generated along with high levels of chip control for efficient evacuation. The inserts have a specially developed channel as part of the geometry to ensure that coolant and lubricant reaches the right place at the cutting edge and on to the chip forming part. Improved insert grades have been established for the programme where coating adhesion and edgeline security have been prioritised to better cope with all the stages of the parting-off plunge.

Importantly, the geometry is designed to ‘fold’ the chip over, making it narrower than the groove being created so that it evacuates without becoming trapped. Almost all machine operators can recount horror stories of trapped swarf when parting and grooving, an issue that can cause both tool and workpiece damage. The latest inserts, which offer high edgeline security, are available in various grades to suit all workpiece materials. There are three PVD variants (GC1105, GC1125, and GC1145), two CVD grades (GC1135 and GC4325 with Inveio technology) and one uncoated grade (H13A). In terms of geometries, there are five for parting-off (-CF, -CM, -CR, -CO and -CL), two for grooving (-TF and -TM) and two Wiper inserts (-CF and -TF).

Selecting an insert always start with the recommended first choice grade. By way of a guide, harder substrates and higher coating thickness give increased wear and temperature resistance, while thinner coatings have better adhesion (it is important to avoid flaking when parting-off to the centre). For increased tool life, make sure to apply all the “hints and tips”, then select a harder grade and/or a grade with thicker coating. Always commence with the recommended cutting speed and feed rate for the material. As a rule of thumb, cutting speed can be increased by the following values when internal coolant is used: 10 bar, vc +10%; 30 bar, vc +30%; and 70 bar, vc +50%.

In terms of geometry, a ‘harder’ and more aggressive chip breaker gives shorter chips but also shorter tool life, while positive and light cutting geometries generally improve tool life. Geometries are also available with either curved or straight cutting edges which offer different chip forming capabilities depending on whether deep or shallow grooves are required. Wiper geometries should be selected where very high surface finish is required.

Ease of use

When it comes to changing a worn insert, there is no need to use a torque wrench. Instead of the traditional screw clamp, which is subject to under- or over-tightening, an innovative clamping solution is deployed on CoroCut QD. This makes use of a simple, quick release key that fool-proofs the entire process of achieving the correct clamping force every time. Furthermore, a unique top and bottom railed insert seat makes for stable and precise insert location.

An optimised, FEM-simulated tip seat angle is provided that inclines the insert 20° to better absorb cutting forces. The result is that when beginning the cut, the main cutting force is directed downwards, introducing inherent stability and security into the process.

Adapting to success Tooling systems that are user-friendly are becoming more sought after in machining because of the difference they make to machine stoppages, as a security factor for correct tool changes and in setting-up.

With this in mind, Sandvik Coromant has developed plug and play adaptors for easy and rapid coolant connection. The assortment covers most common machine tool interfaces for connecting shanks and parting blades in turning centres, and QS™ stops for sliding head machines.

Stable internal grooving

The latest advance to the CoroCut QD concept makes it possible to deliver reliable machining for internal deep grooves with the addition to the programme of CoroTurn SL blades. This added process flexibility is supported by the modularity of the CoroTurn SL interface, which enables tool assemblies to be optimised for specific applications.

Internal grooving requires stability and tooling solutions that keep vibration to a minimum. With this in mind, the stable clamping mechanism on CoroCut QD tools is now supported by the potential to use Silent Tools™ damped boring bars for vibration-free machining with long overhangs. For tube-shaped components, typically found in the oil and gas industry, this is welcome news that enables deep internal grooving with high process security.

For internal grooving using the CoroTurn SL blades, the Serration Lock (SL) interface is extremely robust and allows users to create a range of tool combinations from a small inventory of adaptors and cutting heads. The maximum cutting depth with CoroTurn SL heads is 40 mm.

Application successes

There are no end of customer success stories for CoroCut QD. For example, when parting-off a stainless steel tube at higher cutting data and with 25 percent decreased cutting widths, CoroCut QD increased tool life by 106 percent, while at the same time reducing cycle time in comparison with the customer’s previously deployed parting system. Another example, this time parting-off a 45 mm diameter stainless steel bar as part of a shower mixer machining process, saw tool life boosted by 283 percent. This meant that the machine could be run for a longer time, thus facilitating unmanned production.

For a process industry component, CoroCut QD was able to machine more than double the number of customer parts compared with a competitor system. The operation involved parting-off a 70 mm diameter steel bar of 195 HB hardness using an emulsion coolant. The application of QD allowed the cutting speed to be increased from 100 m/min (from 90 m/ min) and feed to be increased from 0.07 to 0.1 mm/rev. What’s more, tool life could be shown of 100 pieces in comparison with just 45 produced by the competitor system, representing a 122 percent increase. The results were equally impressive when parting off a 46 mm diameter stainless steel bar (320 HB) for an automotive valve. The use of CoroCut QD and an internal emulsion allowed cutting speed to be boosted to 105 m/min (from 85 m/min) and feed to be increased from 0.15 to 0.17 mm/rev. In addition, CoroCut QD demonstrated a tool life of 220 pieces versus just 120 completed by the competitor system, a gain of 83 percent.

At another customer which had been experiencing issues for some time in terms of unpredictable tool life and lack of productivity, CoroCut QD delivered remarkable results. A key aspect of the problem was that the tools in use had external coolant only. This led to chip control issues and a need for pecking during the part-off, which slowed the process down. By switching to CoroCut QD, the customer could machine four times the amount of 54 mm diameter stainless steel pump adaptors compared with the previous parting tool, while also increasing the cutting speed. By applying high precision internal coolant, chip control was improved considerably, thus eliminating the need for a pecking cycle. All together it saved the customer 34 hours in production time per year and led to an impressive 43 percent productivity increase.

Womens Running Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login