Both committed to excellence, the champagne house behind Veuve Clicquot Ponsardin and Cermex collaborate on an end-of-line packaging system

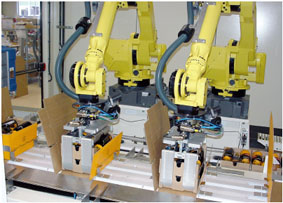

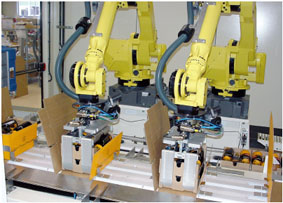

REGARDED by consumers as the most exclusive and the most prestigious champagne, Veuve Clicquot Ponsardin ranks second in the world in terms of sales. The champagne's success is not left to chance; the house demands total quality at all stages of product development. This includes generating original ideas for packaging designs that present a challenge in terms of automation for each new packaging launch. Partner of Veuve Clicquot Ponsardin since 1994, with approximately 20 machines installed, Cermex delivers the solutions that owe as much to its wide experience in the field, with more than 200 references within large champagne houses, as to the pertinence of its research. Cermex's lead in terms of robotics, command of speed, ergonomics and automation of format changeovers as well as its ability to produce reliable solutions which protect the products and their packaging contributed significantly to the attribution of this new contract. Close collaboration continues The latest result of this collaboration is an installation that is both unusual and innovative in many respects. From the start of the project, the technical, production and maintenance departments at Veuve Clicquot Ponsardin were deeply involved in the project for automating a new line.

Three conditions marked the new line five: the launch of a new secondary packaging; the launch of Veuve Clicquot Design Boxes for the sale of individual bottles; and the increase in production capacity with a required speed of 8 500 bottles/hour. Further complicating the project, the line was to handle 16 different formats initially, with the option of dealing with the presentation boxes as well as bottles in the future. The specification stipulated total automation combined with an extreme flexibility with regard to the multiple formats to be handled in short production runs. Naturally, the integrity of such fragile products and the quality of the finished packaging were to be taken into account. Focused on the requirements The new line installed at Veuve Clicquot Ponsardin integrates new intelligence solutions amongst the most advanced in the market. Three major advances particularly contributed to the quality of the solution. Firstly, robot integration, combining speed, protection and precision throughout each phase, backed up by a complete range of loading arms (delta, 2, 4 or 6 axes). They simplify product collating and case loading operations as well as various additional operations such as layer card insertion and creation of product assortments. Secondly, automated format changeovers, from the motorisation of setting points to the robot's participation in adjusting certain elements, including assistance in tooling management and changeover. Finally, product protection and the quality of the finished packaging, obtained as much by the technology as by quality control at each stage. In addition, product facing and shelf-ready packaging combine to achieve a top-quality finished packaging with greater shelf impact. The result was a high-performance and cutting-edge end of line, which consisted of the following: Tray forming (28 cycles per minute): one erector from an existing line plus one latest-generation F272 erector System for merging 2 lanes into 1: designed to collate trays formed separately and control quality prior to infeed into the tray packing zone

AN110 numerical axis gantry packer (8 500 bottles/hour): bottle infeed, spacing, gripping and laying flat, then loading top to tail into trays; presentation box infeed, spacing, turning, gripping and laying flat top to tail on their base or on their side; and corrugated tra

Shop Women's Sneakers by Brand REGARDED by consumers as the most exclusive and the most prestigious champagne, Veuve Clicquot Ponsardin ranks second in the world in terms of sales. The champagne's success is not left to chance; the house demands total quality at all stages of product development. This includes generating original ideas for packaging designs that present a challenge in terms of automation for each new packaging launch. Partner of Veuve Clicquot Ponsardin since 1994, with approximately 20 machines installed, Cermex delivers the solutions that owe as much to its wide experience in the field, with more than 200 references within large champagne houses, as to the pertinence of its research. Cermex's lead in terms of robotics, command of speed, ergonomics and automation of format changeovers as well as its ability to produce reliable solutions which protect the products and their packaging contributed significantly to the attribution of this new contract. Close collaboration continues The latest result of this collaboration is an installation that is both unusual and innovative in many respects. From the start of the project, the technical, production and maintenance departments at Veuve Clicquot Ponsardin were deeply involved in the project for automating a new line.

REGARDED by consumers as the most exclusive and the most prestigious champagne, Veuve Clicquot Ponsardin ranks second in the world in terms of sales. The champagne's success is not left to chance; the house demands total quality at all stages of product development. This includes generating original ideas for packaging designs that present a challenge in terms of automation for each new packaging launch. Partner of Veuve Clicquot Ponsardin since 1994, with approximately 20 machines installed, Cermex delivers the solutions that owe as much to its wide experience in the field, with more than 200 references within large champagne houses, as to the pertinence of its research. Cermex's lead in terms of robotics, command of speed, ergonomics and automation of format changeovers as well as its ability to produce reliable solutions which protect the products and their packaging contributed significantly to the attribution of this new contract. Close collaboration continues The latest result of this collaboration is an installation that is both unusual and innovative in many respects. From the start of the project, the technical, production and maintenance departments at Veuve Clicquot Ponsardin were deeply involved in the project for automating a new line.  Three conditions marked the new line five: the launch of a new secondary packaging; the launch of Veuve Clicquot Design Boxes for the sale of individual bottles; and the increase in production capacity with a required speed of 8 500 bottles/hour. Further complicating the project, the line was to handle 16 different formats initially, with the option of dealing with the presentation boxes as well as bottles in the future. The specification stipulated total automation combined with an extreme flexibility with regard to the multiple formats to be handled in short production runs. Naturally, the integrity of such fragile products and the quality of the finished packaging were to be taken into account. Focused on the requirements The new line installed at Veuve Clicquot Ponsardin integrates new intelligence solutions amongst the most advanced in the market. Three major advances particularly contributed to the quality of the solution. Firstly, robot integration, combining speed, protection and precision throughout each phase, backed up by a complete range of loading arms (delta, 2, 4 or 6 axes). They simplify product collating and case loading operations as well as various additional operations such as layer card insertion and creation of product assortments. Secondly, automated format changeovers, from the motorisation of setting points to the robot's participation in adjusting certain elements, including assistance in tooling management and changeover. Finally, product protection and the quality of the finished packaging, obtained as much by the technology as by quality control at each stage. In addition, product facing and shelf-ready packaging combine to achieve a top-quality finished packaging with greater shelf impact. The result was a high-performance and cutting-edge end of line, which consisted of the following: Tray forming (28 cycles per minute): one erector from an existing line plus one latest-generation F272 erector System for merging 2 lanes into 1: designed to collate trays formed separately and control quality prior to infeed into the tray packing zone

Three conditions marked the new line five: the launch of a new secondary packaging; the launch of Veuve Clicquot Design Boxes for the sale of individual bottles; and the increase in production capacity with a required speed of 8 500 bottles/hour. Further complicating the project, the line was to handle 16 different formats initially, with the option of dealing with the presentation boxes as well as bottles in the future. The specification stipulated total automation combined with an extreme flexibility with regard to the multiple formats to be handled in short production runs. Naturally, the integrity of such fragile products and the quality of the finished packaging were to be taken into account. Focused on the requirements The new line installed at Veuve Clicquot Ponsardin integrates new intelligence solutions amongst the most advanced in the market. Three major advances particularly contributed to the quality of the solution. Firstly, robot integration, combining speed, protection and precision throughout each phase, backed up by a complete range of loading arms (delta, 2, 4 or 6 axes). They simplify product collating and case loading operations as well as various additional operations such as layer card insertion and creation of product assortments. Secondly, automated format changeovers, from the motorisation of setting points to the robot's participation in adjusting certain elements, including assistance in tooling management and changeover. Finally, product protection and the quality of the finished packaging, obtained as much by the technology as by quality control at each stage. In addition, product facing and shelf-ready packaging combine to achieve a top-quality finished packaging with greater shelf impact. The result was a high-performance and cutting-edge end of line, which consisted of the following: Tray forming (28 cycles per minute): one erector from an existing line plus one latest-generation F272 erector System for merging 2 lanes into 1: designed to collate trays formed separately and control quality prior to infeed into the tray packing zone  AN110 numerical axis gantry packer (8 500 bottles/hour): bottle infeed, spacing, gripping and laying flat, then loading top to tail into trays; presentation box infeed, spacing, turning, gripping and laying flat top to tail on their base or on their side; and corrugated traShop Women's Sneakers by Brand

AN110 numerical axis gantry packer (8 500 bottles/hour): bottle infeed, spacing, gripping and laying flat, then loading top to tail into trays; presentation box infeed, spacing, turning, gripping and laying flat top to tail on their base or on their side; and corrugated traShop Women's Sneakers by Brand

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login