The number of plastic parts which are painted and coated is growing relentlessly – in a practically unlimited scope of diversity. Requirements placed on the quality and individuality of painted surfaces are increasing continuously as well. At the same time, srising cost pressure and demand for environmentally sound production are making more efficient, flexible and resource-conserving painting processes necessary.

Not only are manufacturers in the automotive industry making more and more use of plastic parts. There’s hardly an area of life today in which we’re not encountered by plastics made primarily of macromolecules. Painting is taken advantage of when the product needs to be furnished with appealing optics and haptics, an individualised appearance, resistance against mechanical, chemical and physical stressing or special functional characteristics. A number of challenges need to be met to this end. These include optimised quality along with strong economic efficiency and sustainability. This is further augmented by ever smaller lot quantities and an increasing variety of colours.

Optimising the painting process

Entrapped dirt particles and other painting defects result in high costs for rework and scrap. In particular companies that paint components made of plastic are impacted by this problem. On the one hand, this is frequently due to high levels of contamination beginning with the injection moulding process and deburring, right on up to extensive of overspray. On the other hand, the great majority of plastics used today have a strong tendency towards the generation of electrostatic surface charges which attract contamination like a magnet. In order to avoid painting defects and optimise quality, it pays to carefully scrutinise the entire process sequence. In as far as possible, this begins with a tooling design which is adapted to downstream painting requirements.

For example, a reduced number of cut-outs provides for an optimised painting process. And rounded component edges can be more easily wetted with paint than sharp ones. Reducing deburring processes to a minimum also contributes to optimised quality – not only because residual burrs or particles resulting from removal of the sprues can lead to stray contamination all the way up into the painting booth. The cleanliness of the tools plays a role as well: painting defects and entrapped dirt particles can be caused by an accumulation of the ingredients of the utilised plastics.

Formulating constituents such as release agents, additives, filler materials and fibres frequently provide plastics with good processing and functional characteristics. However, if they end up on the surface they may impair paint adhesion. A further challenge is the minimal level of surface energy demonstrated by many plastics. Furthermore, the trend towards water-based paints and process-reduced coatings is placing greater demands on substrate surfaces.

Reliable cleaning or pre-treatment of the surface is therefore indispensable. Where the cleaning of plastic parts is concerned, there’s a trend towards dry processes such as CO2 snow-jet, plasma and steam cleaning with superheated steam. These processes frequently permit cost savings and reduced space requirements for cleaning processes, as well as integration of the cleaning process into the painting line, and they also make good ecological sense. Electrostatic charging of the plastic surfaces can be counteracted by means of ionisation.

In order to avoid adhesion problems with difficult to paint, non-polar plastics such as polypropylene (PP) and polyethylene (PE), their surfaces are activated before painting. Common processes used for this purpose include gas phase fluorination, atmospheric-pressure plasma activation, corona treatment and flaming.

Cutting the steps

Reducing the number of steps required for painting makes a considerable contribution to the goals of increased efficiency and reduced costs per unit. And thus the trend is moving towards painting processes which provide the desired results with just a single coat. Corresponding painting systems are available with solvent as well as water-based paints. Use of these systems necessitates corresponding pre-treatment of the surfaces of the parts.

Other approaches to streamlining the painting process also involve the eradication of possible causes of loss such as atomiser over-spray, as well as losses due to colour changeovers, during application and in the paint supply lines. Among other options, this can be accomplished through the use of electrostatically supported paint guns and high-speed rotary atomizers, which achieve application efficiency levels of greater than 90%. Application systems which permit minimised use of rinsing agents and shortened colour changeover times further support the cost-cutting measures.

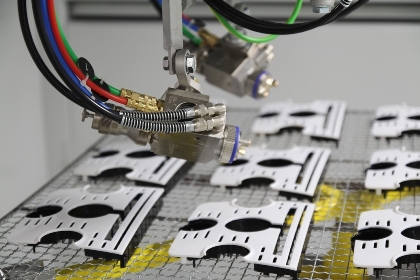

The trend towards automated application remains unbroken as well. And it’s no wonder because in addition to reduced material consumption, it also results in better reproducibility of the painting results and lower scrap rates. Automated paint application has a positive effect expressed in terms of savings because it’s easier to switch from fresh exhaust air systems to recirculating air for conditioning the paint booth. Energy savings of 60% to 70% can be achieved. Intelligent paint logistics also result in reduced material consumption.

In addition to dryers, overspray removal is one of the hungriest energy consumers in the painting process. Where conventional paint drying is concerned, optimised air routing through sluice and tunnel areas, as well as improved heating units and waste-heat utilisation systems assure pennywise consumption of costly energy. Infrared drying offers an alternative which can also be used for temperature-sensitive workpieces. The radiation penetrates the material and dries the paint layer from the inside out. This prevents the occurrence of a skin or bubbles on the surface, and paint drying is accelerated.

Conventional wet scrubbing for overspray consumes a great deal of energy and water. Dry scrubbing systems can be used to obtain savings in this area. Various solutions are available. They make use of different scrubbing concepts such as brushes, electrostatics, powder and special carton constructions.

Matching paint systems to requirements

Fundamentally, high quality, efficient painting of plastics necessitates a paint system which is ideally matched to the substrate, the utilised system technology and the requirements specified for the finished product. In the case of solvent-based paints which are still widely used for coating plastics, solvent emissions are significantly reduced by very-high and ultra-high-solid paint systems. Water-based paint systems continue their advance too. New developments with formulations based on innovative raw materials reach the same quality levels and the durability of conventional solvent-based paints. Depending on the degree to which the surfaces are subjected to stressing, they’re available as multi-coat systems consisting of a primer, a basecoat and a clear coat (or top coat and clear coat), or as a single-coat surface finish with single or 2-component systems including a broad range of colours and effects. The systems are individually matched to the application’s respective requirements and process conditions. Amongst others, new developments in the field of paint include a system which has been specially developed for coating carbon-fibre reinforced plastics. It’s distinguished by good adhesion, high levels of UV stability and resistance to scratching and chemicals in accordance with automotive standards. The coating system is based on a transparent primer with excellent durability. This makes it possible to obtain large layer thicknesses per application and thus to effectively and economically conceal surface defects in composite materials. The highly transparent clear coat, which is matched to the primer and the substrate, protects the material.

PaintExpo – Leading International Trade Fair for Industrial Coating Technology - covers the entire process sequence in the field of coating technology and offers a comprehensive overview of the latest developments in the areas of liquid painting, powder coatings and coil coating – from pre-treatment right on up to quality control. PaintExpo will take place at the exhibition centre in Karlsruhe, Germany, from the 19th through the 22nd of April, 2016. For details, visit: www.paintexpo.de.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login