Sumitomo (SHI) Demag is highlighting one of its injection molding solutions at NPE 2015 (booth W623) - micromolding of a POM gear that plays a vital role in a unique new cataract surgery device developed by Eye Care and Cure (ECC) of Tucson, AZ (eyecareandcure.com).

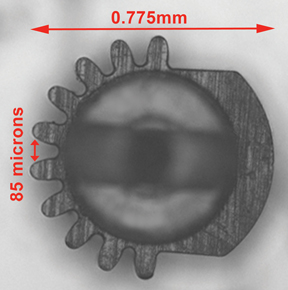

An SE30DUZ direct-drive all-electric equipped with the SL Screw assembly will mold a 0.524-gram gear that rotates the surgical blade in the new I-core Capsulorrhexis Instrument from ECC. The gear will be molded in a Sansyu FineTool (Takahama City, Japan) single-cavity cold-runner mold on loan from micromolder Makuta Technics of Shelbyville, Indiana (makuta.com). A robot from Yushin America, Inc. (NPE Booth W763) will remove the micro-sized part.

SHI appreciates the opportunity to partner with these companies in presenting its innovative product and in demonstrating a challenging process. According to John F. Martich III, V.P. and Chief Operating Officer of Sumitomo (SHI) Demag’s U.S. operations. “When you consider the micron-measured precision

requirements of the gear teeth on this part and the importance of the function they perform — it’s hard to think of a better way to showcase the precision capabilities of our equipment.”

The I-core device is used to create a capsulotomy, which is a circular opening in the human eye’s capsular bag that holds the lens that focuses light onto the retina. When a cataract forms, it clouds the lens so that vision becomes impaired or even blocked. The surgical procedure that removes the clouded lens material requires a uniform opening into the capsular bag. Many different devices have been developed to create the opening but often are difficult to use and are typically slow. While certain laser systems can perform the process, these systems are very expensive and not suited for easy portability.

Specifically designed for small facilities and remote or underdeveloped regions, the I-core device provides a fast, cost-effective and portable solution. The single-use, pre-sterilized device is compact and performs a uniform circular opening in the capsule in a matter of seconds. The device fits through a micro incision and gives the surgeon better skills than many of the older techniques. It operates by transferring motion from a lever arm to the tiny gear that rotates the blade attached to it.

In traditional injection molding, shear heat develops due to dragging resistance of the resin between the screw flights and the barrel. This causes fluctuation of the molten resin density and various other problems. The SL (Spiral Logic) Screw assembly avoids these problems by eliminating shear heating instability.

With the SL Screw assembly, the GS loading system matches the speed of the screw and can feed or meter the material even pellet-by-pellet. The screw is designed with no compression zone and the problem of stagnation or degradation of the melt in the barrel is eliminated. Additionally, the GS valve, which replaces a check ring, is a positive-locking non-return valve that prevents back-flow of material into the barrel. The result is even resin pressure stability the entire length of the screw, a highly stable process and shot-to-shot repeatability.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login