The booming plastics market in Vietnam has driven domestic companies to strive and upgrade their production processes in order to release quality products. In this area, Tan Lap Thanh Plastic Co., Ltd. has been establishing its niche as the company moves forward to raise its efficiency. International Plastics News for Asia had the chance to talk to Lam Tuan Dung, General Manager of Tan Lap Thanh Plastic on the company’s operations and directions of Vietnam’s plastics industry.

Please give an overview on the operation of Tan Lap Thanh Plastic? What are its major products? Where is the factory located?

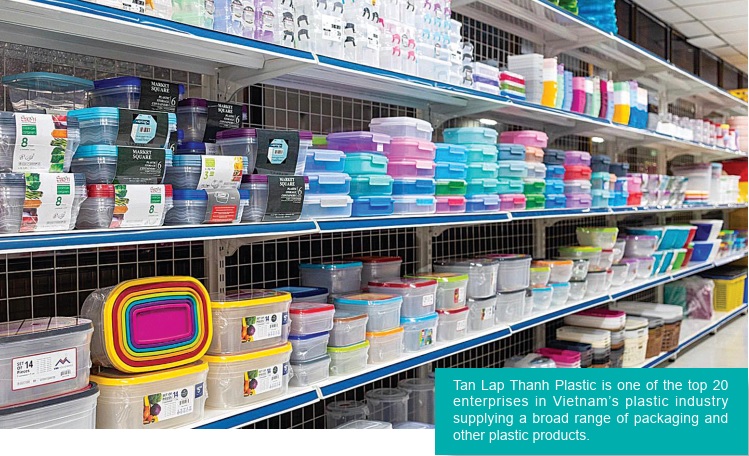

Mr. Lam: The company was established in 1993 as a family enterprise. After 30 years of continuous improvement in our production process, optimisation of quality, upgrading of our production technology, and expanding the scale of development, Tan Lap Thanh Plastic has moved to become one of the top 20 enterprises in the plastics industry in Vietnam. It has 1,000 employees and technicians, and the company's factory is located in Tan Binh District, Ho Chi Minh City with an area of 3 hectares, while the warehouse is located in Long An Province with an area of 5 hectares with the expansion of the production scale.

The main products of the company are furniture, daily necessities, industrial products, and processing of accessories for various industries.

Mr. Lam Tuan Dung, General Manager of Tan Lap Thanh Plastic Co., Ltd.

What are the unique advantages of Tan Lap Thanh Plastic over other companies in the plastics industry in Vietnam?

Mr. Lam: At the beginning of this year, Vietnam has announced a remarkable economic performance of 7.02% GDP growth and 11.29% manufacturing growth in 2022. Just by looking at the figures, you can feel the vigor of this developing country in Southeast Asia.

There is a growing number of manufacturing factories, more big brands being launched and coupled with the Vietnamese government's active investment policy, Vietnam is gradually becoming a new "factory of the world." It is expected that the plastics industry in Vietnam from 2023 to 2032 will continue to grow, the market size will be further expanded, as the country becomes a new base for the plastics processing industry and related industry chain.

Within these developments, Tan Lap Thanh Plastic is also expanding to supply the growing needs of the market. After the pandemic, each industry also gradually resumed production to meet market demand growth. However, market competition has become very fierce. But Tan Lap Thanh Plastic has been able to cope with these market conditions due to its inherent strengths and experience in meeting the customers’ requirements and adoption of advanced production technology. More important, the company has been monitoring the needs of the market to quickly respond to market demand.

Compared with other counterparts, Tan Lap Thanh Plastic has maintained its focus of not directly competing with other counterparts but on self-improvement, constantly launching new plans, initiating policies for self-reform, self-improvement, optimising the quality of late service to improve customer repurchase volume. In addition, our company used to focus on injection moulding products, processing industrial parts, with the market changes and market trends our company spread to develop other categories.

Tan Lap Thanh Plastic has been very active in Vietnam’s plastics industry. What is your overall assessment of the industry and how is the company responding to these conditions?

Mr. Lam: According to Vietnam's official statistics, in recent years, Vietnam's processing and food packaging industry has been able to register stable growth, an average annual growth rate of 15-20% and is expected to improve further. With this double-digit annual growth rate, Vietnam's packaging and printing industry has become a very attractive industry. Vietnam's demand for plastic products is growing, but the country's local demand for raw materials is limited and largely dependent on imports.

According to the Vietnam Plastics Association, the country's plastics industry needs an average of 2 million to 2.5 million raw materials per year, but 75-80% of the raw materials are dependent on imports. The association said earlier that as the Covid-19 pandemic began to ease, the demand for plastics started to pick up and PP and PE imports began to grow, yet some suppliers have also increased their prices. However, Tan Lap Thanh Plastic still maintains a price structure, giving the market a stable supply and the most affordable unit price.

The Association of Vietnam Retailers (AVR) estimates that Vietnam's own population of more than 90 million people, coupled with a rapidly growing number of tourists each year along with the general growth and development of the retail sector, has helped make the country's food, beverage and pharmaceutical sectors a fertile ground for investors, which in turn has stimulated the growth of the domestic packaging industry. Currently, food and beverages account for the highest proportion of the monthly expenditure structure of Vietnamese consumers, with share of about 35% of expenditure. The value of the Vietnamese population's annual food consumption is estimated at 15% of GDP and is on an upward trend.

It is worth noting that our company, with its unique market advantages and labour resources, has now become attractive and trusted by well-known domestic brands, and orders are rising. At the same time, our company is constantly expanding our presence by developing new products to supply the packaging industry and so on. Plastics have specific properties depending on the type. However, most plastics tend to have common properties such as chemical and corrosion resistance, heat resistance, light weight and varying strength levels, aside from being low cost, easy handling and availability of different colours. These factors make plastics the best choice for packaging in the Vietnamese market, thus making plastic packaging the largest plastic application in the country.

In the packaging industry, plastics are used in healthcare, food and beverage, consumer products, personal care packaging, and home/garden sectors. Food and beverage packaging accounts for the largest market share in the plastics market, where plastics are used in the production of bottles, boxes, jars, plastic utensils and cups, among others. Vietnam's packaging industry has experienced rapid growth due to increasing demand for consumer goods and food & beverage. Household and growing commercial applications such as containers, plastic bags, boxes, cutlery, etc. are expected to increase the demand for plastics in the packaging industry.

How important is acquiring the right technology to the overall operations of the company?

Mr. Lam: In terms of technology and equipment, as most of the local enterprises in the plastics industry in Vietnam are small and medium-sized enterprises (SMEs), they rely mainly on imports in terms of technology and equipment. A number of machinery and equipment enterprises have successively set up local production bases, stock warehouses, subsidiaries, and after-sales service points to take advantage of the low-cost advantage on the one hand, and to meet the demand of the local market in the vicinity on the other hand.

Vietnam’s plastics industry is growing by an average of 6% annually, with injection moulding technology accounting for the highest proportion. This technology is used in the production of plastic parts and components production for household equipment, home electronics and automobiles. Packaging, automotive, electronics and other industries are expected to lead the market in this phase. The processing and packaging industry in Vietnam has been rated as an attractive industry for machinery and equipment suppliers with double-digit annual growth.

The most important element in the selection of equipment is the durability of the equipment to ensure the quality of the product as a prerequisite to supply and meet market demand. In this area, we rely on Chuan Lih Fa as our supplier for injection moulding machine to boost our production efficiency and product quality.

In the future, the Vietnamese plastics industry will continue to be an attractive market and Tan Lap Thanh Plastic is constantly developing new products to expand our market reach.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login