Plastics have, since long, been a part of the automotive industry. History dates back to 1950s when plastics were used in multiple applications but with time, not only have the applications increased, so have the utilities and the innovative

techniques by which polymers can be put to use in various forms and shapes, offering added benefits and sustainability.

Plastics are used in three broad categories in automobiles: interiors, exteriors and under-the-hood (UTH) applications. The usage of plastics is justified; they offer reduced weight, moulded-in colours, good insulation properties and ease of manufacture.

However, with the increased use of plastics, it is imperative to ensure sustainability too. Estimates predict more than three billion vehicles will ride the roads in the imminent future, making fuel economy, safety, sustainability and eco-friendly products an issue of concern today. Vishnu Shankar, Associate Director and Head, Chemicals and Materials Practice, Middle East, North Africa and South Asia, Frost & Sullivan said: “With rapid improvements in technology

in the coming years, bio-based materials are expected to be available for large scale commercial applications. These materials would offer the combination of improved performance properties and reduced carbon dioxide emissions.”

Original Equipment Manufacturers(OEM) are working towards the right balance; offering sustainable, cost effective and efficient automobiles with no compromise on performance, comfort or the pocket. DuPont has launched an important concept of innovation and sustainability for this sector by focusing on solutions across eight automotive themes; sustainability, alternative drive, light-weighting, improved performance, powertrain efficiency, total system cost, safety, and comfort and design.

DuPont works with the ambition to tie up with stakeholders and collaboratively devise solutions which offer cleaner, energy-efficient cars.

New materials for lightweight parts

DuPont Performance Polymers collaborates with major manufacturers and dealers to develop new, innovative and sustainable products, systems, applications and parts that help alleviate fossil fuel dependence while ensuring environmental consciousness. The company have been lauded for the efforts too. DuPont materials, design and development support were featured in two automotive components honoured at the 44th Society of Plastics Engineers (SPE) Automotive Innovation Awards Competition. Renault's win in the "Most Innovative Use of Plastics" award in the Chassis & Hardware category featured DuPont Zytel in flexible coolant pipes. The constant velocity joint (CVJ) half-shaft driveaxle boot seal using DuPont Hytrel TPC/ET thermoplastic polyester elastomer was selected as the 2014 Hall of Fame winner.

DuPont Zytel polyamide resins for rigid and flexible coolant pipes are geared to achieve long-term resistance to aggressive water/glycol and road salts –to temperatures from -40°C to +125°C – while delivering processing efficiencies and weight saving.

Another company, HEXPOL TPE has also developed thermoplastic elastomers specifically for automotive mats using its range Dryflex AM. Other applicative uses of DryflexAM include floor mats, coin mats, fascia mats and trim.

Sven-M. Druwen, European sales coordinator for HEXPOL TPE commented on the innovation: “Our teams work hand-in-hand with our automotive customers to develop solutions that address new and emerging demands. With governments’worldwide enacting fuel efficiency and carbon emissions laws, one of the ways car manufacturers are looking to address these regulations is vehicle light weight. By reducing the weight of each component they can look to reduce the weight of the whole vehicle. That is one of the reasons we have developed our TPEs for automotive mats, they have a lower specific gravity compared to several alternative materials, you can therefore not only create lighter-weight parts, but you can also produce more parts per kilogram of material”.

Fuel efficiency as target

Traffic and carbon emissions are a continuous concern for car manufacturers as the heavier the car, the greater the emissions.

Bayer MaterialScience’s materials and solutions offer the flexibility to make vehicles lighter, economical and fuel efficient. If the weight of an average car is reduced by 100 kgs., it will consume around 0.3 litres less fuel over a course of 100 kilometers. Bayer’s plastic polycarbonate is a highly transparent, break resistant and light material which makes a perfect substitute for metal and glass, either independently or in combination. Polycarbonate comes handy in automotive glazing, which can be used for side, rear, panoramic windows or rear hatches. Components made of polycarbonate carry almost 50% less weight than their glass counterparts. LED lenses used in headlights, when made from polymer are also quite light in weight.

BASF also recently introduced an alternative to the typical thermoset technology – a zero-emission thermoset technology. Acrodur® is a water-based formaldehyde-free cross linking resin that creates one byproduct during curing which is water. The conventional thermoset process releases formaldehyde during the cross linking process, which is toxic in nature.In terms of mechanical performance, Acrodur products offer benefits of light-weight and sustainability, significant in the automotive industry as manufacturers strive to reduce weight with no compromise on performance, sustainability or efficiency of the automotive.

Role in automotive industry’s future

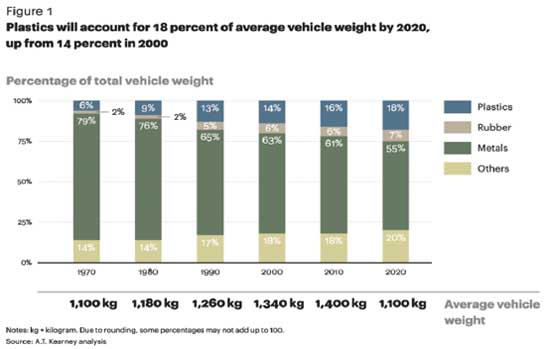

According to insights issued by A.T. Kearney, a leading global management consulting firm, engineered plastics are forming a huge chunk of two major industries – chemical and automotive – which also gives rise to alarming environmental concerns. Legislations across countries globally are churning out laws to curb emissions and car makers are keener to deploy light materials, plastics and plastic components. A.T. Kearney suggests that more than one hundred types and grades of plastics are used in any average vehicle. Polypropylene is generally used in dashboards, wheel covers and some engine parts; Polyurethane (PUR) is employed in seats; Polyethylene (PE) is deployed for carpets and Polyamide (PA) in parts which are heatand chemical-resistant. Mass-volume plastics such as acrylonitrile butadiene styrene (ABS), PP, PUR and nylon make up 70% of the plastics found in an average car while composites and higher-end plastics account for the rest.

While plastics consumption is all set to grow in the automotive industry, A.T. Kearney has identified major challenges for this industry, despite a significant opportunity for chemical companies.

- Price: Since prices are oil-dependent, the volatility exists.

- Steel: Steel is still cost-effective compared to plastics and is innovation friendly, whether it is product or process-based; its performance has improved over the years as well.

- Shortage: Given that plastics supply is not matching up to the growing demands, there may be a certain amount of shortage especially when it is required for immediate use.

- Recyclability: Various types and grades of plastics pose a fair amount of difficulty in recycling. However, this factor remains controllable with bio-sourced and recyclable components. Bio-plastics are derived from renewables; hence the oil dependency is also considerably less.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login