Notwithstanding global uncertainties, enthusiasm for air travel in Asian countries continues to grow, creating countless opportunities for aerospace manufacturers. Singapore is well-equipped to capture the demand for aviation-related services. In line with this, FAG Aerospace, a part of the Schaeffler Group, opened its first aerospace bearing remanufacturing centre for the Asia Pacific region in Singapore.

Andreas Schick, CEO Schaeffler Asia Pacific, said, “Singapore is an important aviation hub and has over one hundred companies related to the aerospace industry in such a small geographic area. With this new facility, we are committed to bring greater value to our customers in the form of fast, reliable and cost-effective access to outstanding service and parts.”

Backed by a large pool of aerospace companies, the region has garnered a quarter of the Asian Maintenance, Repair and Overhaul (MRO) market, according to Singapore Economic Development Board. The country’s aerospace industry has grown at an average rate of 10 percent in the last two decades. Today, it is the most comprehensive aerospace MRO hub in Asia, accounting for a quarter share of the region's MRO output.

Aerospace bearing remanufacturing centre

Schaeffler’s investment is part of an ongoing initiative to strengthen its footprint in the region to give its customers faster and wider access to its advanced products and technologies. FAG Aerospace has developed and manufactured specialty bearings, integrated bearing systems as well as high-precision components for the aviation and aerospace industries. Renowned for their reliability and quality, FAG Aerospace components can be found in most of the leading airplane models in operation today, including the Airbus 380 and the Boeing 787 Dreamliner.

The remanufacturing facility is designed as per the best practice layout, technologies, equipment and workflow from Schaeffler’s existing aerospace bearing remanufacturing centres in Europe and North America. The 500 m2 floor area is optimised to fulfil the high global standards of FAG Aerospace and as mandated by aviation authorities. The facility offers service inspection Level 1 and 2 components and also provides original OEM spare parts replacement. After refurbishment, the bearings will be as “good as new”.

“FAG Aerospace Singapore is the first company to offer bearing refurbishments for the growing aviation industry in this region. Leading global aerospace companies expect a major boom in the aviation sector in Southeast Asia within the next 10 years. This new facility in Singapore enables us to stay close to our customers and grow together with them in this important aviation hub,” said Mark Gabel, Vice President Industrial Aftermarket SEA.”

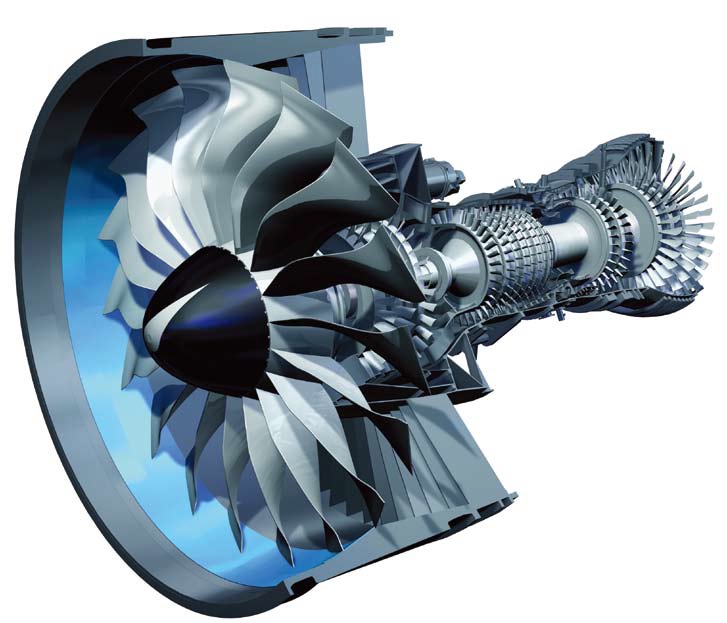

Capable aircraft engines

FAG Aerospace's latest aircraft engine ball bearing redefines the performance limits for high-speed bearing supports in main shafts. As part of the collaborative project “Effective Oil System”, conducted under the Aviation Research Program (LuFo) funded by the Federal Ministry for Economic Affairs and Energy, FAG Aerospace has broken new ground by designing an engine bearing that for the first time exceeds the speed parameter of four million millimetres per minute und uses only minimal cooling oil quantities. The new bearing represents a significant technological leap in the development of more efficient engines and could reduce the consumption of the world’s passenger aircraft fleet by up to 200,000 tons of fuel annually.

The newly developed ball bearing has been validated on a Schaeffler test stand where the testing program requirements, i.e. the simulated flight cycle, were coordinated in close collaboration with the project partner MTU Aero Engines.

FAG Aerospace is the leading development partner for performance-enhanced, more efficient and environmentally-friendly bearing systems for next-generation aircraft and helicopter engines, such as the PW1000G geared turbofan

FAG Aerospace is the leading development partner for performance-enhanced, more efficient and environmentally-friendly bearing systems for next-generation aircraft and helicopter engines, such as the PW1000G geared turbofan

The cooling design enables a specific adjustment of the maximum permissible ring temperatures using the same oil quantities as for conventional bearings. This means that almost 70 percent higher speed parameters are achieved with identical bearing temperatures and oil quantities, so that current materials and cooling oils can be used despite higher circumferential speeds. In turn, if the speed parameters remain the same and smaller quantities of cooling oil are used, then the bearing temperatures will be up to 25 degrees Celsius lower and power losses reduced by up to 25 percent. All this adds up to increased efficiency and reliability of the bearing support.

The aircraft engine bearing also features integrated oil damping of vibration loads. In addition, the performance-enhanced “duplex hardened” raceways provide greater robustness, strength and wear resistance, while reducing the rolling contact loads at the same time. The higher efficiency and reliability of the new ball bearing is also due to direct cooling of the outer ring and the ceramic balls that help to reduce friction and weight. Bearings in aerospace applications need to work with the utmost reliability even under the most critical operating conditions.

These days, in the initial phase during take-off, speed parameters of up 2.4 million millimetres per minute are achieved with the engine bearing investigated. However, to meet the future requirements of airlines as well as the constraints imposed by environmental and climate protection legislation, further improvements will be necessary with regard to the mechanical and thermal efficiency of aircraft engines over the next 20 years. As a consequence, enhanced speed and thermal load capabilities will be required for the bearings. And this calls for innovative materials, cooling concepts, manufacturing and heat treatment procedures, as well as advanced calculation and simulation methods.

(From L to R) Ramdas Cherupara, President Schaeffler South East Asia, Andreas Schick, CEO Schaeffler Asia Pacific and Matthias Biegner, Accountable Manager FAG Aerospace Singapore poised to cut the ceremonial ribbon at the opening ceremony of FAG Aerospace (Singapore) Pte. Ltd.

(From L to R) Ramdas Cherupara, President Schaeffler South East Asia, Andreas Schick, CEO Schaeffler Asia Pacific and Matthias Biegner, Accountable Manager FAG Aerospace Singapore poised to cut the ceremonial ribbon at the opening ceremony of FAG Aerospace (Singapore) Pte. Ltd.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login